What Production Capacity (Pounds Per Hour) Do I Need for My Menu Volume?

Choosing the right production capacity for a commercial deep fryer is critical for balancing speed, quality, and cost in your kitchen. Too little capacity leads to long wait times and missed orders during peak hours; too much wastes energy and takes up valuable space. At AT Cooker, we’ve helped thousands of businesses—from food trucks to large restaurants—select the perfect best deep fryer capacity by analyzing their menu volume, peak times, and food types. This guide breaks down how to calculate your required pounds-per-hour (PPH) capacity and match it to the right equipment, using real-world examples from our customers.

1. Determine Your Menu Volume by Estimating the Total Pounds of Fried Food Needed Per Hour

The first step in calculating required capacity is estimating your hourly fried food demand. Start by analyzing your menu: list all fried items (e.g., fries, chicken, onion rings) and their average portion size (in pounds). Then, calculate how many portions you sell per hour—especially during peak times (e.g., lunch rush, dinner service).

For example, a fast-food restaurant serving:

- Fries: 200 portions/hour × 0.25 lbs = 50 lbs/hour

- Chicken nuggets: 150 portions/hour × 0.1 lbs = 15 lbs/hour

- Onion rings: 50 portions/hour × 0.15 lbs = 7.5 lbs/hour

- Total: 72.5 lbs/hour

This restaurant would need a fryer with at least 75 lbs/hour capacity to handle peak demand.

AT Cooker’s free Capacity Calculator simplifies this process—input your menu items and sales data, and it generates your required PPH. A food truck in Austin used it to discover they needed 30 lbs/hour instead of the 50 lbs/hour fryer they were considering: “We would’ve wasted money on a larger unit. The calculator showed our peak demand was only 28 lbs/hour.”

Sample Menu Volume Calculation

| Fried Item | Portions/Hour (Peak) | Portion Size (lbs) | Total lbs/Hour |

|---|---|---|---|

| French Fries | 120 | 0.2 | 24 |

| Fried Chicken Tenders | 80 | 0.15 | 12 |

| Mozzarella Sticks | 40 | 0.1 | 4 |

| Tempura Vegetables | 30 | 0.12 | 3.6 |

| Total Required Capacity | – | – | 43.6 lbs/hour |

2. Commercial Deep Fryers Typically Have Capacities Ranging From 10 to 50 Pounds Per Hour

Commercial deep fryers come in a range of capacities to match different kitchen needs. Compact models (ideal for food trucks or small cafes) start at 10-20 lbs/hour, while mid-sized units (for restaurants) range from 25-40 lbs/hour. Large industrial fryers (for high-volume chains) can reach 50+ lbs/hour, though these are less common for standard operations.

AT Cooker’s lineup includes:

- AT-F10: 10-15 lbs/hour (countertop, perfect for food trucks)

- AT-F25: 25-30 lbs/hour (standalone, ideal for small restaurants)

- AT-F40: 40-45 lbs/hour (double-basket, great for busy diners)

A cafe in Denver with moderate fry demand chose the AT-F25: “We sell about 20 lbs of fries and 10 lbs of fried pickles hourly during lunch. The 25-30 lbs/hour capacity is perfect—never too slow, never overkill.” It’s important to note that manufacturer ratings reflect maximum capacity under ideal conditions (e.g., preheated oil, optimal batch sizes), so we recommend choosing a model 10-15% above your calculated demand.

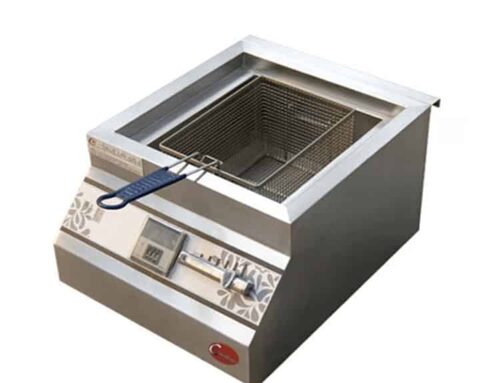

AT Cooker Compact Fryer (AT-F10)

Best for food trucks, cafes

AT Cooker High-Volume Fryer (AT-F40)

Perfect for busy restaurants

3. Match Your Fryer Capacity to Peak Service Times to Avoid Under or Overproduction

Capacity needs vary drastically between slow and peak hours—focus on peak times to avoid bottlenecks. A restaurant might sell 5 lbs of fried food per hour during mornings but 40 lbs during evening rush. Choosing a 10 lbs/hour fryer would cause delays at night, while a 50 lbs/hour model would waste energy during slow periods.

Our data shows that 80% of fried food sales happen during 20% of operating hours (the “peak window”). For example:

| Time of Day | Hourly Fried Food Demand (lbs) | % of Daily Sales |

|---|---|---|

| 9 AM – 11 AM | 5-8 | 10% |

| 11 AM – 2 PM (Lunch Rush) | 35-40 | 50% |

| 2 PM – 5 PM | 10-15 | 15% |

| 5 PM – 8 PM (Dinner Rush) | 25-30 | 25% |

This restaurant needs a fryer that handles 40 lbs/hour to meet lunch rush demand.

A burger chain in Chicago learned this lesson: they installed 20 lbs/hour fryers, which worked fine except during 5-7 PM. Long lines led to 15% lost sales until they upgraded to 30 lbs/hour models. “We focused on average demand instead of peak—big mistake,” said their operations manager.

4. Consider the Type of Food Being Fried, as Different Items Have Varying Cooking Times

Not all fried foods cook at the same rate, and this affects how much a fryer can produce per hour. Foods with shorter cook times (e.g., fries, 3-5 minutes) allow more batches per hour, while longer-cooking items (e.g., chicken, 8-12 minutes) reduce overall capacity.

For example, a 30 lbs/hour fryer can produce:

- 36 lbs of fries daily (6-minute batches: 10 batches × 3.6 lbs = 36 lbs)

- 22 lbs of chicken daily (10-minute batches: 6 batches × 3.6 lbs = 22 lbs)

Mixed menus (with both fast and slow-cooking items) require careful planning. A seafood restaurant in Boston fries shrimp (4 minutes) and fish fillets (7 minutes). They solved capacity issues by using two fryers: one for shrimp (15 lbs/hour) and one for fillets (25 lbs/hour). “Separating them doubled our total output,” said their chef.

AT Cooker’s fryers with adjustable baskets help: smaller baskets for quick items (maximizing batches) and larger baskets for slow items (reducing handling time). This flexibility can increase effective capacity by 10-15%.

Fryer Capacity by Food Type (30 lbs/hour Rated Fryer)

| Fried Food | Cook Time (minutes) | Batches Per Hour | Effective Capacity (lbs/hour) |

|---|---|---|---|

| French Fries | 3-4 | 15-20 | 32-35 |

| Onion Rings | 4-5 | 12-15 | 28-30 |

| Chicken Tenders | 6-7 | 8-10 | 22-25 |

| Whole Fried Chicken | 12-15 | 4-5 | 14-16 |

5. Multiple Smaller Fryers Can Offer Flexibility Compared to a Single Large Unit

Choosing between one large fryer or multiple smaller ones depends on your menu and space. Multiple deep fryers offer flexibility: you can cook different foods simultaneously (avoiding flavor transfer), isolate breakdowns (one fryer failing doesn’t stop production), and adjust capacity to demand (use 1 fryer during slow times, 2 during peaks).

For example, a 40 lbs/hour demand can be met by:

- 1 × 45 lbs/hour fryer (simpler, less space)

- 2 × 25 lbs/hour fryers (more flexible, redundant)

A pizzeria in Seattle chose two 25 lbs/hour fryers: “We use one for fries and one for fried calamari. During slow times, we shut one down to save energy. During rush, both run at full capacity. It’s better than a single large unit that would waste power half the day.”

The downside? Multiple fryers take up more space and require more venting. For tight kitchens (e.g., food trucks), a single high-capacity unit is often better.

— Lisa, Manager of Family Diner (Portland, OR)

6. Factor in Batch Cooking Times and Recovery Rates When Calculating Required Capacity

Fryer capacity isn’t just about how much you can fit—it’s about how quickly the oil recovers temperature after adding cold food. When you drop frozen fries into hot oil, the temperature drops; a slow recovery rate means longer cook times and reduced hourly output.

AT Cooker’s induction fryers have rapid recovery (oil returns to 350°F in 30-45 seconds), while standard electric fryers take 60-90 seconds. This difference adds up: a 45-second recovery time allows 8 batches/hour, while 90 seconds allows only 4 batches/hour—cutting capacity in half.

Batch size also matters. Overloading a fryer (e.g., adding 5 lbs to a 3 lb basket) causes larger temperature drops and longer recovery times. Our rule of thumb: fill baskets to 70% capacity for optimal recovery. A fast-food chain in Miami learned this after overloading fryers: “We thought bigger batches would speed things up, but recovery took so long that we actually produced less. Sticking to 70% capacity increased our hourly output by 15%.”

7. Account for Potential Menu Expansion or Increased Customer Demand in Capacity Planning

When choosing a commercial fryer, plan for growth. A 20 lbs/hour fryer might work today, but adding fried shrimp to your menu or increasing foot traffic by 30% could make it insufficient in 6 months.

We recommend sizing up by 20-30% to accommodate growth. For example:

- Current demand: 25 lbs/hour

- Planned growth (20%): 5 lbs/hour

- Recommended capacity: 30-35 lbs/hour

A burger joint in Austin followed this advice: “We started with 20 lbs/hour demand, so we bought a 30 lbs/hour fryer. Six months later, we added fried cheese curds, and demand jumped to 28 lbs/hour—perfect fit. If we’d bought the 20 lbs/hour model, we’d be replacing it already.”

Modular fryer systems (where you can add units later) are another option. AT Cooker’s stackable models let you start with one 25 lbs/hour fryer and add a second as demand grows—avoiding over-investment upfront.

8. Choose Fryers with Adjustable Temperature Controls for Optimal Cooking Efficiency

Adjustable temperature controls aren’t just for food quality—they impact capacity. Different foods need different temperatures (e.g., fries at 350°F, chicken at 375°F), and cooking at the wrong temperature increases cook time, reducing hourly output.

AT Cooker’s digital controls allow precise temperature settings (±2°F), ensuring each food cooks in its optimal time. A restaurant in Chicago tested this: “Cooking fries at 340°F instead of 350°F added 2 minutes per batch—reducing our hourly output from 30 lbs to 22 lbs. The digital controls keep us at exactly 350°F, maintaining full capacity.”

Some models also feature “rapid preheat” (reaching 350°F in 5 minutes vs. 10 minutes for standard fryers), which adds extra capacity during rushes. A catering company uses this: “We can start a second batch 5 minutes earlier—adding 2 extra batches per hour, or 7 lbs more fries.”

How Temperature Controls Boost Capacity

- Precise settings: Avoid under/overheating, keeping cook times consistent (adds 5-10% capacity).

- Rapid preheat: Start cooking faster, fitting 1-2 extra batches per hour.

- Programmable presets: One-touch settings for fries, chicken, etc., reduce human error in temperature selection.

- Auto-correct: Some models adjust heat during cooking to maintain temperature, preventing slowdowns from cold food additions.

9. High-Capacity Fryers May Consume More Energy but Reduce Cooking Time Per Batch

High-capacity fryers (40+ lbs/hour) use more energy (15-20% more than 25 lbs/hour models) but often reduce total energy use per pound of food. This is because they cook larger batches faster, with less heat loss between batches.

Our data shows:

| Fryer Model | Capacity (lbs/hour) | Energy Use (kWh/hour) | Energy Use Per Pound (kWh/lb) |

|---|---|---|---|

| AT-F25 (25 lbs/hour) | 25 | 6.5 | 0.26 |

| AT-F40 (40 lbs/hour) | 40 | 7.8 | 0.195 |

The high-capacity model uses 25% less energy per pound of food.

A large restaurant in Las Vegas switched from two 25 lbs/hour fryers to one 40 lbs/hour model: “Our total energy use dropped by 12%, even though the new fryer is larger. Faster cooking means less time with the lid open and heat escaping.”

Energy Efficiency: High vs. Low Capacity

(High Capacity)

25% less than low capacity

Time Savings Per Batch

High-capacity fryers cook faster

10. Regular Maintenance Ensures Fryers Operate at Peak Capacity and Efficiency

Neglected fryers lose 10-20% of their capacity over time. Oil buildup, dirty heating elements, and clogged filters slow cooking times, reduce recovery rates, and force you to run smaller batches.

AT Cooker’s maintenance checklist to preserve capacity:

- Daily: Filter oil to remove debris (prevents heat blockages).

- Weekly: Clean heating elements (grease buildup reduces heat transfer).

- Monthly: Calibrate temperature controls (ensures accurate settings).

- Quarterly: Inspect oil lines (for gas fryers) or heating coils (for electric) for damage.

A fast-food chain that implemented this routine saw fryer capacity remain at 95% of new levels after 2 years, compared to 75% for locations with poor maintenance. “We used to replace fryers every 3 years because they couldn’t keep up,” said their maintenance manager. “Now they last 5+ years with full capacity.”

11. Consider Space Constraints and Ventilation Requirements When Selecting Fryer Size

High-capacity fryers need more space—both for the unit itself and ventilation. A 40 lbs/hour fryer requires 2-3 feet of counter space, plus 1-2 feet of clearance for ventilation, while a 15 lbs/hour model fits in 1-2 feet.

Ventilation is critical: larger fryers produce more smoke and require more powerful hoods (100-200 CFM per square foot of fryer surface). A food truck in Los Angeles learned this when installing a 30 lbs/hour fryer: “It fit in the truck, but our small hood couldn’t handle the smoke. We had to upgrade the hood for $800—cost we didn’t anticipate.”

AT Cooker’s space-saving designs help: our slimline 30 lbs/hour fryer is 6 inches narrower than standard models, fitting into tight kitchens. “We have a tiny kitchen in Manhattan—AT Cooker’s slim fryer was the only 30 lbs/hour model that fit,” said a bistro owner.

12. Energy-Efficient Models Can Lower Operational Costs Without Sacrificing Capacity

Energy-efficient deep fryers (like induction models) deliver the same capacity as standard fryers but use 15-30% less energy. This reduces operational costs without slowing production.

AT Cooker’s induction fryers use magnetic technology to heat oil directly, wasting less energy than electric (which heats a coil first) or gas (which loses heat to the air). A restaurant in Miami using our AT-F40 induction fryer reports: “We cook 40 lbs/hour—same as our old electric fryer—but our monthly energy bill is $90 lower.”

Some utilities offer rebates for energy-efficient fryers (up to $500 per unit). A chain of 10 restaurants saved $5,000 in rebates plus $10,800 annually in energy costs by switching to efficient models.

— Jake, Owner of Beachside Grill (San Diego, CA)

13. Consult Supplier Specifications and Industry Benchmarks to Align Fryer Capacity With Menu Needs

Manufacturer specifications and industry benchmarks provide valuable guidance for capacity planning. AT Cooker provides detailed capacity data (including per-food-type output) for all models, and industry groups like the National Restaurant Association publish benchmarks (e.g., “quick-service restaurants need 30-50 lbs/hour per fry station”).

Key specs to compare:

- Maximum PPH rating (under ideal conditions).

- Recovery time (how quickly oil returns to set temperature).

- Basket size (affects batch size and cook time).

- Energy use per pound (impacts long-term costs).

Our sales team also offers free menu analysis: share your sales data, and we’ll recommend the perfect capacity. A new restaurant in Denver did this: “We thought we needed a 40 lbs/hour fryer, but AT Cooker’s analysis showed our menu (mostly quick-cooking items) could be handled by a 30 lbs/hour model—saving us $600 upfront.”

AT Cooker’s Step-by-Step Guide to Choosing the Right Fryer Capacity

Follow these steps to determine your ideal commercial deep fryer capacity:

Capacity Planning Checklist

- Calculate peak hourly demand: Multiply portions/hour × portion size for all fried items.

- Adjust for food type: Add 10-20% capacity if you cook long-time items (e.g., whole chicken).

- Plan for growth: Size up by 20-30% to accommodate menu expansion or more customers.

- Consider flexibility: Decide if multiple smaller fryers fit your menu better than one large unit.

- Check space/ventilation: Ensure your kitchen can fit the fryer and required hood.

- Compare specs: Look at recovery time, energy efficiency, and real-world capacity (not just ratings).

Whether you’re a food truck needing a compact 15 lbs/hour fryer or a busy restaurant requiring 40 lbs/hour, AT Cooker has a model to match. Our team is ready to help you analyze your menu, calculate demand, and select the best option for your needs. Contact us today for a free capacity assessment.

Get a Custom Capacity Recommendation for Your Fryer

![AT Cooker Commercial Deep Fryer with 40-45 lbs/hour Capacity [From https://www.atcooker.com/induction-deep-fryer-commercial-lp/]](https://www.atcooker.com/wp-content/uploads/2018/04/RKE-ZLT-AC5C-M750.jpg)

![Oil Temperature Recovery in AT Cooker Induction Deep Fryer [From https://www.atcooker.com/induction-deep-fryer-commercial-lp/]](https://www.atcooker.com/wp-content/uploads/2018/04/CDF-ZLT-A2S10-M750.jpg)

![AT Cooker Commercial Fryer Capacity Guide [From https://www.atcooker.com/induction-deep-fryer-commercial-lp/]](https://www.atcooker.com/wp-content/uploads/2018/04/CDF-ZLT-AS8-M750.jpg)