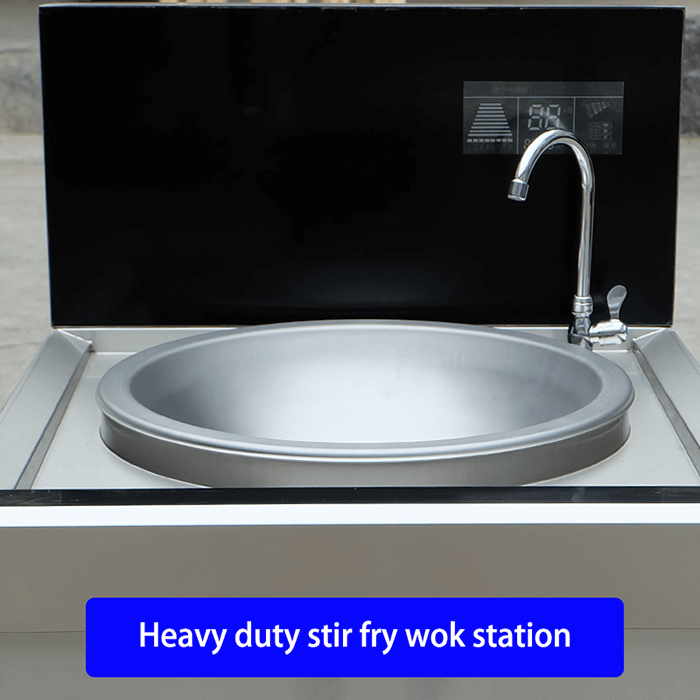

Does Sensor Lag on Commercial Induction Woks Ruin the Chef’s Cooking Flow?

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

There is a nightmare scenario for any chef transitioning from gas to electric: You are in the middle of a high-speed dinner rush, tossing a heavy wok of fried rice. Every time you lift the pan to flip the food, the induction cooker beeps. The power cuts. You set it back down, and there is a 2-second pause—a “lag”—before the heat kicks back in. In those 2 seconds, the pan cools, the rice stops frying, and your rhythm is shattered. This is the phenomenon of commercial induction wok sensor lag.

For professional Asian cuisine, where maintaining stir fry rhythm is as important as the recipe itself, this lag is unacceptable. It turns a fluid dance into a stuttering, frustrating battle with the machine. At AT Cooker, we understand that induction pan detection speed isn’t just a technical spec; it’s the heartbeat of the kitchen. In this article, we dissect the mechanics of pan detection, why it causes lag, and how modern engineering has virtually eliminated it.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Mechanics of Pan Detection: Why Induction Heat Cuts Off During Tossing

Induction works by creating a magnetic field that induces electrical currents (eddy currents) in the ferrous metal of the wok. When you lift the wok, that connection breaks. To prevent the machine from blasting magnetic energy into thin air (which could damage the internal electronics), the system engages a safety protocol called “Pan Detection.”

The system stops full power output and starts “pulsing”—sending small test signals to check if the pan has returned. The delay between the pan landing back on the ceramic glass and the machine resuming full power is the “sensor lag.” In cheaper models, this loop can take 1-3 seconds. In heavy duty asian cooking equipment like ours, this is reduced to milliseconds.

2. Comparing Lag Times: Residential Cooktops vs Professional 30KW Wok Stations

Many chefs have a bad first impression of induction because they tried a residential unit. A home cooktop prioritizes safety over speed. If you lift the pan, it might beep five times and shut off entirely. It assumes you are done cooking.

A Professional 30KW Wok Station is built with a different logic. It assumes you are still cooking. It knows that tossing is part of the process. Therefore, its “tolerance window” is much tighter. While a home unit lags by 2000ms (2 seconds), an AT Cooker unit targets a reconnection time of under 100ms, which is faster than the human eye can perceive.

3. The Impact of “Micro-Disconnects” on Maintaining Wok Hei Temperatures

“Wok Hei” requires sustained temperatures above 230°C. If your cooker cuts out every time you toss, you experience “Micro-Disconnects.” Imagine driving a car and taking your foot off the gas every 5 seconds. You lose momentum.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

4. Technique Adaptation: Sliding vs Lifting to Maintain Magnetic Connectivity

One way chefs adapt to induction vs gas chef workflow differences is by modifying their technique. Instead of lifting the wok high into the air (which breaks the magnetic link), they keep the wok base closer to the ceramic bowl, using a “sliding” toss motion.

However, we believe the machine should adapt to the chef, not the other way around. While keeping the wok close helps, our sensors are sensitive enough to detect the return of the wok even after a high, aggressive toss, ensuring that electronic wok burner responsiveness feels natural regardless of style.

5. Chef Frustration Factors: Dealing with Error Beeps During Rapid Service

There is nothing more annoying than a machine that screams at you. Many generic induction woks emit a loud “BEEP” every time the pan is lifted, signaling an “E0” (No Pan) error. In a busy kitchen, this constant beeping adds to the sensory overload and stress.

AT Cooker units are programmed with “Silent Detection.” When you lift the pan, the machine quietly goes into standby. When you put it back, it silently resumes full power. No beeps, no errors, just cooking. This small detail significantly reduces chef frustration factors.

6. The Role of Deep Concave Coils in Extending the Vertical Magnetic Zone

The shape of the coil matters. A flat coil has a very short magnetic throw (about 2-3cm). Our commercial wok heat recovery system uses a “Deep Concave” coil design that hugs the curve of the wok.

This design extends the “Vertical Magnetic Zone.” This means you can lift the wok slightly higher (up to 4-5cm in some sweet spots) and still maintain some magnetic coupling. This buffer zone allows for small tossing movements without breaking the power connection at all, preserving the commercial induction wok sensor lag from even becoming an issue.

7. Miao Hui Technology: Millisecond Power Restoration for Seamless Cooking

We’ve engineered a solution specifically for this: “Miao Hui” (Instant Return) technology. This proprietary algorithm pre-loads the capacitors when a disconnect is detected. Instead of shutting down the inverter, it keeps the system in a “ready-to-fire” state.

The moment the sensor detects the ferrous mass of the wok returning, the energy is released instantly. The lag is virtually zero. This seamless transition is what allows a chef to switch from a gas wok to an AT Cooker induction wok and feel zero difference in the rhythm.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

8. Why Some Input Lag is Necessary to Protect IGBT Inverters from Voltage Spikes

Why not have zero lag? Technically, you need some delay for protection. If you pump 30KW of power into a circuit the nanosecond a pan touches the glass, you risk a voltage spike that could blow the IGBTs (Insulated Gate Bipolar Transistors).

The art of engineering is finding the balance. We set our “Soft Start” ramp-up time to be fast enough to be imperceptible to the chef (under 0.1 seconds) but controlled enough to protect the expensive internal components. This ensures heavy duty asian cooking equipment longevity without sacrificing performance.

9. The “Rhythm Breaker”: How Delayed Heating Affects High-Speed Menu Turnaround

If you are cooking 200 portions of Fried Kway Teow an hour, a 1-second delay per toss adds up. If you toss 20 times per dish, that’s 20 seconds lost. Over an hour, that’s huge.

By eliminating this “Rhythm Breaker,” AT Cooker helps you maintain a high-speed menu turnaround. The chef stays in the zone, the food comes out faster, and the queue of tickets gets cleared efficiently.

10. Digital Processing Power: How 32-Bit Chips Eliminate Perceptible Sensor Delay

The speed of detection is limited by the speed of the processor. Older analog systems or 8-bit chips are slow to calculate the resistance changes.

We utilize advanced 32-bit Infineon digital processing chips. These processors can sample the coil environment thousands of times per second. They calculate the presence of the pan, the temperature, and the required power adjustment faster than a blink of an eye, effectively eliminating any perceptible sensor lag.

11. The “Clicking” Sound: Distinguishing Between Pulse Checks and Actual Power Loss

Chefs sometimes hear a faint “clicking” sound when the pan is lifted. This is not a malfunction; it is the “Pulse Check.” The coil is sending magnetic pulses to search for the pan.

Hearing this is actually a good sign—it means the system is active and hunting for your wok. Understanding this helps chefs realize that the machine hasn’t shut down; it’s simply waiting in ambush, ready to deliver full power the moment the wok lands.

12. Standardizing the Toss: Why Consistent Height Improves Sensor Reliability

While our machines are robust, physics is physics. The further you move the pan, the weaker the signal. We recommend training staff to standardize their toss height to stay within the optimal “Re-Connect Zone” (usually within 10-15cm of the glass).

Consistent movement yields consistent results. By understanding the invisible magnetic field, a chef can manipulate the wok to keep the power engaged exactly when they need it, mastering the commercial induction wok sensor lag dynamic completely.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts: Don’t Let Lag Slow You Down

Cooking is about flow. Your equipment should extend your capabilities, not limit them. With AT Cooker’s advanced sensor technology and “Miao Hui” instant return, you can say goodbye to the annoying beeps and power drops of the past. Cook with the speed of gas and the power of induction.

Test Our “Zero Lag” Technology Today

Contact us to see a video demonstration of our sensor speed in action.