Save Money Instantly: How Commercial Induction Woks Cut Costs Every Time the Chef Tosses

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Watch a chef at a wok station. The motion is rhythmic and constant: scoop, toss, catch, toss again. In a traditional gas kitchen, that roaring flame burns continuously, whether the wok is touching the metal ring or flying in the air. That “air time”—the seconds the pan is lifted—represents 100% wasted energy. Over a year, this invisible waste burns a hole in your profit margin.

But what if every time the chef lifted the pan, your utility meter stopped running? This is the reality of commercial induction pan detection energy savings. By utilizing advanced magnetic sensors, AT Cooker induction woks automatically cut power the millisecond the physical connection is broken. In this article, we’ll calculate the true value of reducing restaurant utility bills through the simple, repetitive act of tossing the wok.

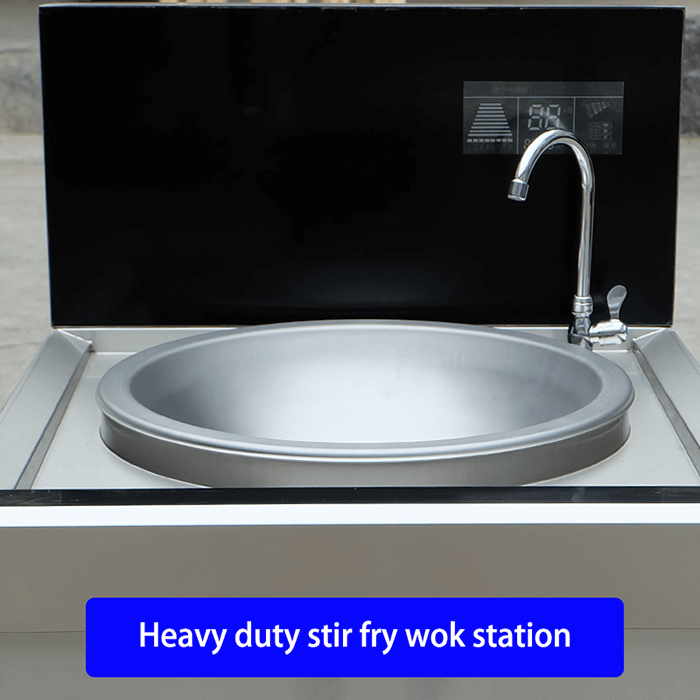

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Physics of the Toss: How Magnetic Decoupling Cuts Power to Zero Instantly

Induction cooking relies on magnetic coupling. The copper coil beneath the glass creates a magnetic field that interacts with the ferrous bottom of the wok. This interaction is binary: connected or disconnected.

When a chef lifts the wok for a toss, the distance between the coil and the pan exceeds the magnetic reach (typically 2-4cm). In a properly engineered system like ours, this physical separation causes “Magnetic Decoupling.” The system detects the loss of load and instantly drops the power consumption from 25KW (or whatever your setting is) to standby mode (approx. 5W-10W). This drop happens faster than the eye can blink.

2. Quantifying “Air Time”: Calculating Energy Waste in Traditional Gas Wok Cooking

Let’s do the math on wok cooking energy waste. A typical 1-minute stir-fry involves roughly 15-20 tosses. Each toss lasts about 1-1.5 seconds. That means for every minute of cooking, the pan is “in the air” for nearly 20 seconds.

With an induction wok, those 20 seconds are “off” time. You are literally only paying for the 40 seconds the food is actually cooking. This efficiency gain is automatic and requires no change in the chef’s behavior.

3. The Accumulative Effect: How Micro-Breaks Save Thousands in Annual Utility Bills

Saving 20 seconds of energy per dish doesn’t sound like much until you scale it. If a busy restaurant serves 400 stir-fry dishes a day, that’s 8,000 seconds (over 2 hours) of “burn time” saved daily per station.

Over a year (360 days), this equates to 720+ hours of high-power energy consumption eliminated. When you factor in commercial electricity rates versus the inefficiencies of gas, the commercial kitchen cost saving is massive—often enough to pay for the induction unit itself within 12-18 months.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

4. Induction vs. Gas Pilot Lights: Comparing Continuous Consumption Profiles

The waste in gas kitchens isn’t limited to cooking time. Pilot lights and “standby” flames consume fuel 24/7. Chefs often leave gas woks running on low even when not cooking because reigniting them is a hassle. This “Continuous Consumption Profile” is a flat line of waste.

In contrast, induction vs gas wok consumption profiles look like a barcode—energy is only used in bursts. When the service lulls, the induction wok uses zero energy. There are no pilot lights. There is no idle burning. This “On-Demand” profile aligns perfectly with the ebb and flow of restaurant service.

5. Smart Sensor Technology: Reacting Faster Than a Chef’s Wrist Movement

The secret to induction wok auto shutoff is in the sensor sampling rate. AT Cooker uses 32-bit processors that check the coil resistance thousands of times per second.

This means the system detects the “lift” before the chef’s wrist has even reached the top of the toss arc. By the time the wok is 2cm off the glass, the power is cut. This ultra-fast reaction time ensures that no energy bleeds out during the transition, maximizing the savings from every single movement.

6. The “30% Rule”: Why Wok Chefs Spend One-Third of Service Time Lifting the Pan

Culinary ergonomic studies show that in high-volume Chinese cooking, the wok is disconnected from the heat source for approximately 30% of the active cooking time. This includes tossing, plating, and cleaning between batches.

If you are using gas, you are paying for that 30%. With energy efficient stir fry equipment like ours, that 30% becomes free. It is a built-in discount on your operational costs that gas simply cannot offer.

7. Reducing Ambient Heat: Why Cutting Power Mid-Toss Lowers Kitchen Temperature

Where does the wasted heat from a gas burner go? Into your kitchen. It heats the ambient air, forcing your HVAC system to work harder. This is a “double penalty”—you pay for the gas to create the heat, and you pay for the electricity to remove it.

By cutting power mid-toss, induction woks eliminate this fugitive heat. The kitchen stays cooler. Staff are happier. And your air conditioning bills drop significantly, adding another layer to the reducing restaurant utility bills strategy.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

8. Visualizing Savings: Using Real-Time Power Displays to Monitor Drop-to-Zero Events

AT Cooker units feature digital displays that show real-time power consumption (KW). You can actually see the savings happening. As the chef cooks, the numbers fluctuate: 25KW… 0KW… 25KW… 0KW.

This visual feedback confirms the smart induction sensors are working. It also helps owners verify that the equipment is responding correctly to the chef’s rhythm, providing peace of mind that every toss is a money-saving event.

9. The “Miao Hui” Balance: Saving Energy Without Losing the Wok Hei Heat Rhythm

Saving energy is great, but not at the expense of food quality. The challenge is “Miao Hui”—restoring power instantly when the pan returns. If the power stays off too long, the pan cools, and the Wok Hei (breath of the wok) is lost.

Our technology strikes the perfect balance. We cut power to save money, but we maintain a “sensing pulse” that allows us to restore full 30KW power within milliseconds of the wok landing. This gives you the best of both worlds: the efficiency of an eco-friendly appliance with the brute force of a traditional dragon burner.

10. Component Durability: Can Inverters Handle Millions of On-Off Cycles Per Year?

A valid concern: does rapid switching wear out the electronics? Standard consumer electronics might fail, but heavy duty asian cooking equipment is built differently.

Our Infineon IGBT modules are designed for high-frequency switching. The “Soft Start” and “Soft Stop” algorithms manage the in-rush current, protecting the components from stress. We engineer our inverters to handle millions of on-off cycles annually, backed by our industry-leading warranty.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

11. Impact on Peak Demand Charges: Reducing Average Hourly KWh Draw

Commercial electricity bills often include “Peak Demand Charges”—penalties for your highest hour of usage. Because induction woks cut power frequently (during every toss), your average hourly KWh draw is lower than your peak potential.

This “smoothing” effect can help keep you in a lower tariff bracket compared to equipment that draws constant high power. It’s a hidden financial benefit of the commercial induction pan detection energy savings mechanism.

12. Owner vs. Chef Perspective: Aligning Culinary Technique with Operational Cost Control

Often, chefs want performance and owners want savings. Induction woks satisfy both. The chef gets a cooler kitchen and instant power response. The owner gets lower bills and less waste.

By automating the savings through the physics of the toss, you remove the need to “police” your staff about turning off equipment. The equipment polices itself, creating a harmonious kitchen where high-quality food and cost control coexist.

Final Thoughts: Turn Motion into Money

Every time your chef tosses the wok, they are creating rhythm, flavor—and now, savings. Switch to AT Cooker and turn that repetitive motion into a cost-cutting machine.

Ready to Slash Your Utility Bills?

Contact us today for a free ROI calculation based on your kitchen’s volume.