The Spinner Effect: Dangers of Wobbling Cookware on Induction

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

You put a pan on the induction stove to heat oil. You turn your back to grab ingredients. Suddenly, the pan starts to rotate on its own, spinning faster and faster. This is the “Spinner Effect”—a dangerous phenomenon caused by warped induction pan spinning. It happens when the base of a cheap pan deforms under heat, turning into a convex rocker that spins on the smooth glass surface.

In a commercial kitchen, a spinning pan is more than a nuisance; it’s a safety hazard waiting to spill 200°C oil onto a chef. At AT Cooker, we engineer cookware and induction surfaces to work in harmony. Understanding why pans spin and how to prevent it is critical for commercial kitchen safety hazards management.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Physics of Thermal Expansion: Why Pans Deform into Convex Shapes

Metal expands when heated. In a poorly designed pan, the bottom expands faster than the sides can accommodate. Since it cannot expand outward (restricted by the sidewalls), the base has nowhere to go but up (concave) or down (convex).

If it buckles downward, the bottom becomes a rounded dome. This creates a single point of contact with the flat induction glass, acting like the pivot of a spinner toy. Any movement causes it to spin uncontrollably.

2. The Friction Deficit: How Smooth Glass Surfaces Exacerbate Instability

Commercial induction cooktops use high-strength microcrystalline glass. It is incredibly smooth to make cleaning easy. Stainless steel is also smooth.

This metal-on-glass interface has very low friction. When you combine this with the “spinner” convexity, you have zero grip. A slight nudge is enough to send a pan sliding across the range, unlike gas grates which physically lock the pan in place.

3. Safety Hazards: The Risk of Hot Oil Spills During Vigorous Stirring

The biggest danger is hot oil. If a chef vigorously stirs a stir-fry or sauce in a spinning pan, the lack of stability can cause the entire vessel to slide off the burner.

4. Magnetic Decoupling: How Air Gaps Trigger Intermittent Heating and Error Codes

A convex bottom creates an air gap between the outer edges of the pan and the induction coil. Magnetic fields weaken rapidly over distance.

If the gap exceeds 3-5mm, the induction sensor may lose the connection (“Magnetic Decoupling”). This causes the unit to pulse on and off or display “E0/No Pan” errors, disrupting the cooking process and potentially damaging the inverter through rapid load switching.

5. The “Dancing” Phenomenon: Vibration Causing Unattended Pans to Slide Off

Even without stirring, a warped pan can move. Boiling water creates vibration. On a convex base, this vibration translates into lateral movement.

We call this “The Dancing Pan.” An unattended pot of stock can slowly vibrate its way to the edge of the stove and fall off. A truly flat base creates a suction-like seal with the glass, preventing this drift.

6. Uneven Heating Consequences: Scorching Food Due to Partial Base Contact

A spinner pan only touches the glass in the center. The center gets superheated, while the edges remain cooler.

This thermal gradient scorches food in the middle while leaving the outer rim undercooked. For delicate sauces or searing, this makes the pan useless. Consistent cooking requires 100% surface contact.

7. Material Thickness: Why Heavy-Gauge Stainless Steel Resists Deformation

Why do some pans warp and others don’t? Thickness. Thin metal (under 1.5mm) has low structural integrity.

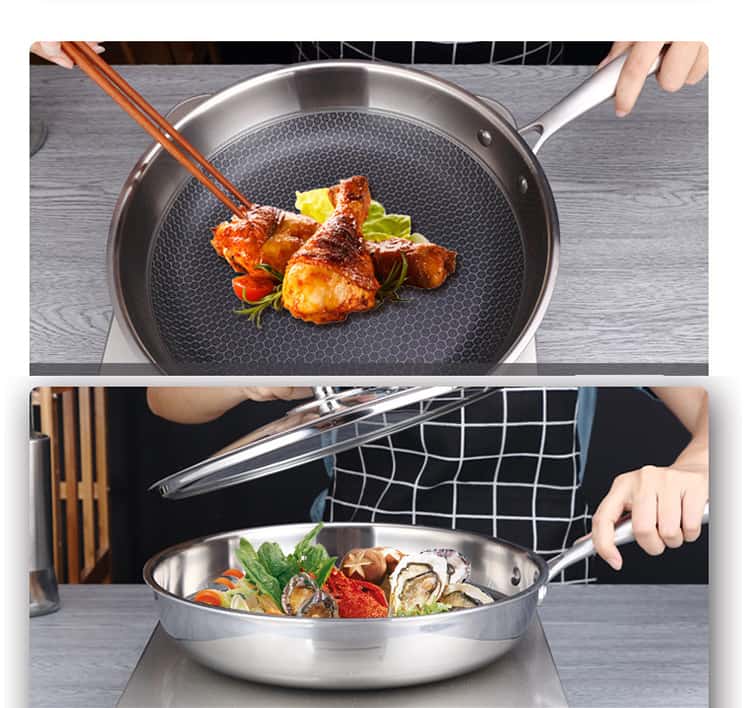

AT Cooker recommends heavy duty stainless steel pan stability standards of at least 2.5mm to 3.0mm thickness. The extra mass resists the thermal torque of rapid heating, maintaining its shape even under the stress of 3500W induction power.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

8. The “Ruler Test”: Verifying Absolute Flatness Before Purchasing Commercial Sets

Before you buy, perform the “Ruler Test.” Place a straight edge (ruler) across the bottom of the pan.

If the ruler rocks back and forth, the pan is convex (a spinner)—reject it. If there is a slight gap in the middle, it is concave (Ao Di). A slight concavity is acceptable (and often engineered), but convexity is a deal-breaker for induction.

9. Tri-Ply Cladding vs. Impact Bonded Discs: Which Construction Maintains Geometry?

Impact bonded bases (a disc glued to the bottom) often have different expansion rates than the pan body, leading to separation and warping.

Tri-Ply Cladding (used in AT Cooker premium lines) fuses the metals into a single sheet. This monolithic structure expands uniformly, maintaining its geometry far better than disc-bottom pans, significantly reducing the spinner effect.

10. Cool-Down Protocols: Preventing Warpage by Avoiding Thermal Shock in Sinks

The fastest way to create a spinner is to take a hot pan and blast it with cold water. The metal contracts violently and unevenly.

Preventing cookware wobble on glass top starts at the sink. Establish a protocol: Pans must cool to hand-warm temperature before washing. This simple habit saves thousands in equipment replacement costs.

11. The “Ao Di” (Concave) Standard: Understanding Pre-Tensioned Base Engineering for Stability

“Ao Di” means “Concave Bottom.” High-quality manufacturers intentionally engineer a slight (0.5%) inward curve to the base.

When the pan heats up, the metal expands downward. The pre-tensioned curve flattens out to become perfectly level. If the pan started flat, it would expand into a convex spinner. This engineering is the secret to stability at high temperatures.

12. Ci Lou (Magnetic Leakage): How Floating Bases Reduce Energy Efficiency and Damage Inverters

A warped pan that floats above the glass causes “Ci Lou” (Magnetic Leakage). The magnetic field isn’t fully absorbed by the pan and radiates outward.

This reflected energy can heat up the induction cooktop’s own internal components and interfere with touch controls. Using stable, flat cookware ensures 100% of the energy goes into the food, protecting both the chef and the machine.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts: Stability is Safety

A spinning pan is a warning sign. Don’t ignore it. Upgrade to AT Cooker commercial-grade, warp-resistant cookware to ensure your kitchen remains safe, efficient, and stable.

Stop the Spin, Start Cooking

Invest in heavy-duty cookware designed for the rigors of commercial induction. Contact us for a catalog.