Hygiene Revolution: Comparing Cleaning One Commercial Induction Bratt Pan vs. Three Separate Machines

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: The most dangerous time in a commercial kitchen is the closing shift. As staff tire, cleaning shortcuts happen. When a kitchen line consists of a fryer, a griddle, and a boiling kettle, there are simply too many corners, gaps, and surfaces to sanitize effectively every night. This creates a hygiene risk. The solution is consolidation. By replacing three machines with a single AT Cooker Commercial Induction Bratt Pan, you don’t just save space; you revolutionize your sanitation protocol. This guide compares the cleaning commercial induction bratt pan workflow against traditional setups to prove why “Less is More” when it comes to hygiene.

In hospital kitchens and institutional catering, HACCP compliance is not optional. Every piece of equipment adds to the cleaning burden. A standard cookline with three separate appliances introduces grease traps, floor gaps, and backsplash seams that harbor bacteria. Hospital kitchen sanitation efficiency depends on reducing these variables.

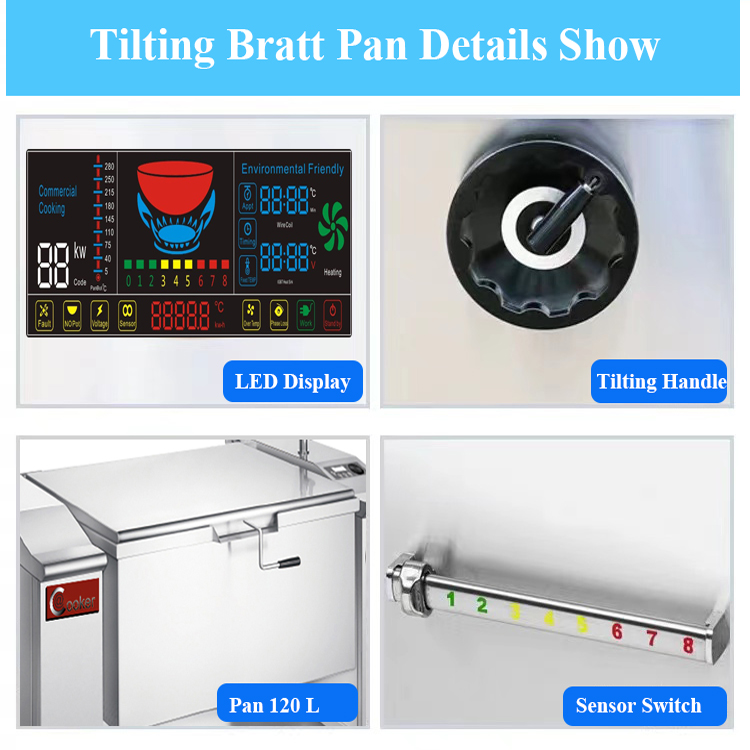

The AT Cooker Tilting Skillet is designed with a “Clean-in-Place” philosophy. Its motorized tilting mechanism, seamless stainless steel body, and lack of open flame components make it the most hygienic tool in the modern kitchen. But how much labor does it actually save?

In this detailed analysis, we perform a Time-Motion study to quantify the hygiene advantages of equipment consolidation.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Time Motion Study: Quantifying Labor Minutes Saved Cleaning One Vessel vs Three

In a standard kitchen, a porter might spend 15 minutes scrubbing a fryer, 15 minutes scraping a griddle, and 15 minutes cleaning a boiling kettle. Total time: 45 minutes.

Cleaning an AT Cooker Induction Bratt Pan involves tilting the pan, spraying it out, and wiping it down. Total time: 10-15 minutes. This reducing kitchen labor costs advantage saves 30 minutes per shift. Over a year, that is 182 hours of paid labor saved—pure profit added to your bottom line.

2. The HACCP Advantage: Reducing Critical Control Points (CCPs) in the Cleaning Schedule

More machines mean more logs. Each piece of equipment is a Critical Control Point (CCP) that must be monitored for hygiene. Three machines mean three checklists, three swab tests, and three potential failure points.

Consolidating to one Bratt Pan simplifies your HACCP plan. You have one surface to validate, making it easier to maintain HACCP compliance equipment standards and pass inspections with flying colors.

3. Eliminating “Grease Migration” Gaps Between Adjacent Stand-Alone Appliances

The 2-inch gap between a fryer and a range is a graveyard for food scraps and grease. It is nearly impossible to clean without unhooking gas lines and moving heavy equipment.

A single Bratt Pan eliminates these gaps. There are no side crevices for grease to migrate into. This seamless installation prevents the buildup of rancid fat that attracts pests and creates fire hazards.

4. The Physics of Drainage: How Motorized Tilting Simplifies Waste Water Removal

Cleaning a fixed kettle requires bailing out soapy water with a bucket—a back-breaking and wet task. A tilting skillet cleaning guide is simple: push a button.

The motorized tilt mechanism pours dirty water directly into a floor trough or bucket. Gravity does the work, preventing spills and reducing the physical strain on your cleaning staff.

5. Water Conservation Analysis: Liters Required to Rinse One Tank vs Multiple Stations

Washing three separate machines consumes triple the water and triple the chemicals. You need three buckets of soapy water and three rinse cycles.

Washing one Bratt Pan requires one cycle. This institutional catering hygiene benefit reduces water consumption by up to 60%, lowering utility bills and reducing the environmental footprint of your kitchen.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

6. Reducing Chemical Exposure: Simplifying Detergent Inventory for a Single Surface Material

Different machines need different chemicals. Fryers need degreasers; griddles need carbon removers. A stainless steel Bratt Pan needs only mild detergent and water.

This simplifies your chemical inventory and reduces staff exposure to harsh caustics. It is safer for the user and cheaper for the operator.

7. The Psychological Factor: How Lowering “Closing Shift” Burden Improves Staff Compliance

When staff are tired at midnight, they cut corners. Staring at three dirty machines is demoralizing. Staring at one is manageable.

By reducing the cleaning workload, you improve staff morale and compliance. It is easier to get a team to perfectly clean one machine than to halfway clean three.

8. Surface Area Calculation: Why Less Exposed Metal Means Fewer Bacterial Harboring Sites

Bacteria live on surfaces. Three machines have 3x the exterior surface area—knobs, legs, sides, and backs—that gather dust and grease.

One Bratt Pan has a fraction of the surface area. The sleek, enclosed stainless steel easy clean design of the AT Cooker unit means there are fewer square inches for bacteria to colonize.

9. Preventing Cross-Contamination: The Safety of Sterilizing One Tank Between Allergen Batches

In a hospital, allergen control is vital. Cleaning a fryer to remove gluten traces is nearly impossible. Cleaning a stainless steel pan is easy.

You can boil water in the Bratt Pan to sterilize it completely between batches. This ability to “reset” the hygiene status of the machine allows for safe cross contamination prevention when switching from gluten-containing to gluten-free meals.

10. Maintenance Hygiene: Eliminating Dust Traps on Gas Lines, Pilot Assemblies, and Knobs

Gas equipment is cluttered with pipes, valves, and pilot assemblies that trap grease and dust. These areas are hard to clean and attract pests.

The AT Cooker induction unit is smooth and sealed. There are no gas manifolds or pilot assemblies to harbor grime. The touch-sensor controls eliminate physical knobs, which are notorious germ vectors.

11. Solving the “Si Jiao” (Dead Corner) Problem: Eradicating Floor Gaps Found in Multi-Unit Lineups

Underneath a lineup of ranges is a dark, dirty tunnel of lost food and grease. It requires moving the equipment to clean properly.

A single Bratt Pan stands on accessible legs or a plinth. The floor underneath is easy to see and easy to mop, eliminating the “dead corners” where hygiene problems start.

12. High-Pressure Wash Compatibility: Utilizing Waterproof Ratings for Rapid “Gun Cleaning” Techniques

Many AT Cooker units are rated IPX4 or higher. This means you can use a spray hose to rinse down the exterior surfaces (carefully avoiding direct intake vents).

This capability speeds up the cleaning process significantly compared to gas units, which often require careful hand-wiping to avoid dampening the pilot or burners.

| Cleaning Metric | 3 Separate Units | 1 Induction Bratt Pan |

|---|---|---|

| Time Required | 45-60 Mins | 10-15 Mins |

| Chemical Use | High (Multiple Types) | Low (Single Type) |

| Gap Cleaning | Difficult (Between units) | None (Single unit) |

| Water Usage | High | Low |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Hygiene is non-negotiable. By consolidating your equipment into a single AT Cooker Commercial Induction Bratt Pan, you make cleanliness the path of least resistance. Save labor, save water, and ensure safety.

With stock ready for immediate delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we can help you revolutionize your kitchen hygiene today. Visit our About Us page to learn more.