How Much Oil Does the Commercial Fryer Hold, and What Is Its Oil Consumption Rate?

For commercial kitchens—from fast-food chains to upscale restaurants—understanding commercial fryers’ oil capacity and consumption rate is critical for controlling costs, ensuring food quality, and streamlining operations. Oil is one of the top recurring expenses for fryer-dependent businesses, so matching a fryer’s oil hold capacity to your daily output, and optimizing consumption via maintenance or technology, can save thousands annually.

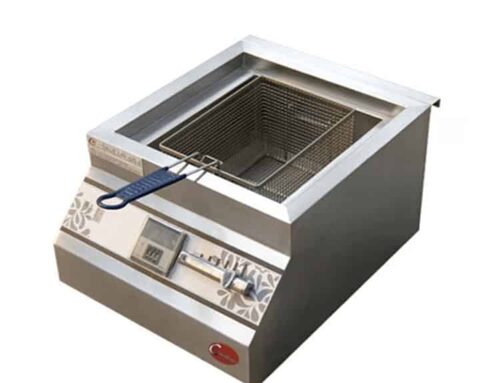

AT Cooker, a leading manufacturer of commercial induction deep fryers, offers models with oil capacities ranging from 10L (8.5 lbs) to 80L (68 lbs), each engineered to balance efficiency and volume. Below, we break down oil hold capacities by fryer type (countertop, freestanding, large-scale), explain key factors influencing oil consumption rate, and share data from AT Cooker’s products to help you make informed decisions. Whether you’re evaluating a countertop deep fryer for a café or a large deep fryer for a stadium concession stand, this guide covers all critical details.

First, it’s important to note oil capacity conversions: 1 liter (L) of frying oil weighs approximately 0.85–0.92 pounds (lbs), depending on oil type (e.g., vegetable oil vs. peanut oil). We’ll reference both metric (L) and imperial (lbs) units to align with global kitchen standards.

1. Commercial Fryers Typically Hold 15 to 60 Pounds of Oil (Varies by Model)

Commercial fryers’ oil hold capacity spans a wide range, tailored to kitchen size and daily demand. Most standard models fall between 15–60 lbs (17–65L), while industrial-grade units (like AT Cooker’s 40L×2 model) can hold up to 73 lbs (80L) for high-volume operations. The key is matching capacity to your output: a small café using a countertop deep fryer needs far less oil than a busy burger chain with multiple deep fryer commercial units.

AT Cooker’s product lineup illustrates this range clearly, with each model’s oil capacity tied to its design and intended use:

- Compact Countertop Models (5KW): Ideal for small kitchens, these hold 8.5–13.8 lbs (10–15L) of oil. For example, the 5KW single-basket fryer has a 10L (8.5 lbs) tank, while the 5KW dual-basket model holds 15L (12.75 lbs). These are perfect for cafes or food trucks frying 50–100 portions daily.

- Mid-Volume Freestanding Models (8–15KW): Designed for restaurants, these hold 19.5–21.16 lbs (23L) of oil. The 23L commercial induction fryer is a bestseller, fitting 23L (21 lbs) of oil—enough to fry 200–300 portions of fries or chicken daily.

- High-Volume Dual-Tank Models (10–12KW×2): For stadiums, hotels, or large chains, these hold 68–73.6 lbs (80L total: 40L×2) of oil. The 40L×2 fryer can handle 500+ portions daily, with separate tanks for different foods (e.g., one for fries, one for chicken).

A small café in Austin uses AT Cooker’s 10L countertop fryer: “We fry 70 portions of onion rings daily—10L of oil lasts 3 days. A larger fryer would waste oil, as we don’t use enough to justify 20L+ capacity.” By contrast, a hotel in Las Vegas uses the 40L×2 model: “We serve 600+ guests for brunch—80L of oil lets us fry nonstop without refilling, which is critical for keeping up with orders.”

| AT Cooker Model | Oil Capacity (L) | Oil Capacity (lbs, Veg Oil) | Power | Ideal Kitchen Type | Daily Portion Output |

|---|---|---|---|---|---|

| 5KW Single-Basket Countertop Fryer | 10L | 8.5 lbs | 5KW | Cafés, food trucks | 50–100 |

| 5KW Dual-Basket Countertop Fryer | 15L | 12.75 lbs | 5KW | Small restaurants, kiosks | 100–150 |

| 23L Freestanding Induction Fryer | 23L | 19.55 lbs | 8–15KW | Mid-sized restaurants, diners | 200–300 |

| 40L×2 Dual-Tank Fryer | 80L (40L×2) | 68 lbs | 10–12KW×2 | Large chains, stadiums, hotels | 500+ |

2. Oil Consumption Rate Depends on Usage Frequency

Oil consumption rate—how quickly oil needs to be replaced—varies drastically based on how often the fryer is used. High-volume operations (frying 4+ hours daily) consume oil 2–3x faster than low-volume kitchens (frying 1–2 hours daily), as constant heating and food exposure accelerate oil degradation.

To quantify this, consider AT Cooker’s most popular models and their typical oil replacement cycles (using vegetable oil, the most common choice for commercial kitchens):

- Low-Volume Use (1–2 hours/day): A 10L countertop fryer used for 1 hour daily (e.g., a café frying breakfast sandwiches) needs oil replacement every 5–7 days. This translates to ~1.4–2L of oil consumed daily, or ~42–60L monthly.

- Mid-Volume Use (3–4 hours/day): A 23L freestanding fryer used for 3 hours daily (e.g., a diner frying lunch and dinner) needs oil replacement every 3–4 days. Daily consumption is ~5.75–7.6L, or ~172–228L monthly.

- High-Volume Use (5+ hours/day): A 40L×2 fryer used for 6 hours daily (e.g., a stadium concession stand) needs oil replacement every 2–3 days. Daily consumption is ~26–40L, or ~780–1,200L monthly.

These cycles are not arbitrary—they’re based on oil quality metrics like free fatty acid (FFA) levels. Once FFA exceeds 1%, oil starts to produce off-flavors and smoke, so replacement is necessary. AT Cooker’s customers confirm these timelines: a fast-food chain in Chicago uses two 23L fryers for 4 hours daily, replacing oil every 3 days. “We track oil quality with test strips—at day 3, FFA hits 1.2%, so we change it to keep fries tasting fresh,” said the kitchen manager.

Usage frequency also impacts “idle degradation”—oil breaks down even when the fryer is on but not cooking. For example, a fryer left on standby for 2 hours daily will consume oil 15% faster than one turned off between uses. This is why AT Cooker’s fryers include a 10-hour auto-shutoff timer—reducing idle time and lowering consumption.

3. Regular Filtration Extends Oil Life, Reducing Consumption

One of the most effective ways to lower oil consumption rate is regular filtration. Food particles (e.g., breading, crumbs) left in oil accelerate degradation by burning and releasing acids, which break down oil molecules. Filtration removes these particles, extending oil life by 30–50% and cutting monthly consumption costs significantly.

AT Cooker’s commercial fryers are designed to simplify filtration, with features that make the process fast and efficient:

- Faucet Drain: All models include a built-in faucet drain that lets staff drain oil directly into a filtration container, no lifting required. The 23L fryer’s drain has a fine mesh screen to catch large particles before filtration.

- Cool-Touch Oil Handles: Filtration is safest when oil is cool (122–140°F), so AT Cooker’s fryers have insulated handles for oil containers, preventing burns during the process.

- Compatible with Filtration Systems: High-volume models (like the 40L×2) work with commercial oil filtration machines, which remove microscopic particles that manual filtration misses—extending oil life by an extra 20%.

A catering company in Miami tested the impact of filtration: “We used to replace oil every 3 days without filtration. With daily filtration (10 minutes after closing), we now replace it every 5 days—saving 40% on oil costs monthly.” For a 23L fryer, this means going from 23L every 3 days to 23L every 5 days—cutting monthly oil use from 230L to 138L, a $192 monthly savings (assuming $3/L for vegetable oil).

The key is consistency: filtration should happen after every busy service, not just when oil looks dirty. Even small, invisible particles cause damage over time. AT Cooker provides a filtration checklist with every fryer, helping staff build the habit into their closing routine.

No Filtration

Oil Replacement Cycle (23L Fryer)

230L Monthly Consumption

Daily Filtration

Oil Replacement Cycle (23L Fryer)

138L Monthly Consumption

Machine Filtration

Oil Replacement Cycle (23L Fryer)

115L Monthly Consumption

4. Induction Fryers’ Precise Temperature Control Slows Oil Degradation

Oil degradation accelerates at temperatures above 375°F (190°C), as high heat breaks down oil’s molecular structure and produces harmful compounds. This is where deep fryer electric induction models shine: their precise temperature control keeps oil within the ideal range (325–375°F), preventing overheating and slowing degradation—directly lowering oil consumption rate.

AT Cooker’s induction fryers use sensor-based PID (Proportional-Integral-Derivative) controllers that adjust heat 10 times per second, maintaining temperatures within ±2°F. This is far more precise than gas fryers (which fluctuate ±5–8°F) or standard electric fryers (±3–4°F). The result? Oil lasts longer because it’s never exposed to damaging high temperatures.

A chicken chain compared AT Cooker’s induction fryer to a gas fryer: “Our gas fryer’s temperature bounced between 360°F and 385°F, so oil degraded fast—we replaced it every 2 days. The induction fryer stays at 370°F exactly, and oil lasts 4 days. We cut oil costs in half.”

Precise temperature control also reduces “smoke point violations”—when oil exceeds its smoke point (400°F for vegetable oil), it becomes unusable immediately. AT Cooker’s fryers include anti-high-temperature warnings that alert staff if oil nears 390°F, giving them time to adjust heat before oil is ruined. This feature alone saves some restaurants 10–15L of oil monthly, as they no longer have to discard overheated batches.

For kitchens frying delicate foods (e.g., tempura, which requires 350°F), this precision is even more critical. A sushi restaurant using AT Cooker’s 15L induction fryer said: “Tempura oil can’t exceed 355°F— the induction fryer’s precision lets us fry 50 portions without oil degradation, while our old fryer ruined oil after 20 portions.”

5. Oil Capacity Is Proportional to Fryer Size (Larger = Higher Demand)

Oil capacity and fryer size are directly linked—larger fryers (bigger physical dimensions) hold more oil because they’re designed for higher demand. This proportionality ensures that fryers can keep up with output without constant refilling, which would disrupt service and increase oil waste (from spills during refills).

AT Cooker’s product dimensions reflect this relationship, with tank size (and thus oil capacity) increasing alongside overall fryer size:

- Countertop 10L Fryer: Product size = 400×400×450mm (compact enough for countertops), tank size = 200×280×180mm (10L oil capacity).

- Freestanding 23L Fryer: Product size = 500×800×950mm (floor-standing), tank size = 340×340×200mm (23L oil capacity).

- Dual-Tank 80L Fryer: Product size = 1000×800×1100mm (large floor model), tank size = 400×400×250mm×2 (80L total oil capacity).

This proportionality is critical for workflow efficiency. A large fryer with a small oil capacity would require constant refilling—for example, a 1000×800mm fryer with only 10L capacity would need refilling every 30 minutes during peak service, causing bottlenecks. Conversely, a small countertop fryer with 23L capacity would be too heavy (21 lbs of oil + fryer weight) to move safely.

A hotel kitchen in Las Vegas learned this lesson: “We initially bought a small countertop fryer with a 20L tank, thinking it would save space. But it weighed 60 lbs when full, so we couldn’t move it—we had to install a permanent counter. We switched to AT Cooker’s 15L countertop model, which is lightweight enough to store when not in use.”

When choosing a fryer, always match oil capacity to both demand and space: use AT Cooker’s product size specs to ensure the fryer fits in your kitchen, and oil capacity to ensure it meets your daily output needs.

6. Food Type Influences Oil Consumption (Breaded vs. Plain)

The type of food you fry has a major impact on oil consumption rate. Breaded or battered foods (e.g., fried chicken, onion rings) shed crumbs and absorb more oil, accelerating degradation. Plain foods (e.g., French fries, mozzarella sticks) produce fewer particles and absorb less oil, so oil lasts longer. This means a kitchen frying mostly breaded foods will need to replace oil 20–30% more frequently than one frying plain foods.

AT Cooker’s customers have seen this firsthand:

- Breaded Food Example: A fried chicken restaurant using the 23L fryer replaces oil every 3 days. “Chicken breading sheds crumbs that burn in the oil, so we have to change it often,” said the owner. Monthly oil consumption: 230L.

- Plain Food Example: A薯条 restaurant using the same 23L fryer replaces oil every 4 days. “Fries produce almost no crumbs, so oil stays clean longer,” said the manager. Monthly oil consumption: 172L.

The difference comes from two factors:

1. Particle Production: Breading flakes off during frying, creating tiny crumbs that settle at the bottom of the tank. These crumbs burn at high temperatures, releasing acids that break down oil.

2. Oil Absorption: Breaded foods have porous surfaces that absorb oil (up to 10% of their weight), while plain foods have smooth surfaces that absorb less (3–5%). This means more oil is lost to the food itself, not just degradation.

To mitigate this, AT Cooker recommends using separate fryers for breaded and plain foods—this prevents cross-contamination of crumbs and extends oil life for both. For example, a restaurant can use one 15L fryer for breaded chicken and another 15L fryer for plain fries, instead of using one 23L fryer for both. A diner in Chicago did this and reported: “Separate fryers let us keep fry oil for 4 days and chicken oil for 3 days—we save 15L of oil monthly compared to using one fryer.”

For kitchens that can’t afford multiple fryers, AT Cooker suggests adding a “crumb basket” (a fine mesh insert) to catch breading particles before they reach the tank. This simple accessory extends oil life by 10–15% for breaded foods.

— Mike, Diner Owner (Chicago, IL)

7. Advanced Oil Management Systems Monitor Quality

Modern commercial fryers often include advanced oil management systems that monitor oil quality in real time, alerting staff when replacement is needed. These systems eliminate guesswork—staff no longer have to rely on visual cues (e.g., oil color) or manual test strips, which can be inaccurate. Instead, sensors measure oil’s FFA levels or conductivity, providing objective data on when to change oil.

While AT Cooker’s standard models use manual test strips (included with every fryer), their high-end 40L×2 model offers an optional oil quality sensor that integrates with the digital display. The sensor:

- Measures oil conductivity every 15 minutes (conductivity increases as oil degrades).

- Displays a “Quality Score” (1–10) on the fryer’s screen—10 = fresh, 3 = replace soon, 1 = replace immediately.

- Sounds an alert when the score drops to 3, giving staff time to plan oil replacement during a lull in service.

A stadium concession stand using this feature said: “We have 6 fryers running during games— the quality sensors let us track each one’s oil status from the kitchen office. We no longer have to send staff to check each fryer, and we never run out of clean oil during peak hours.”

For high-volume operations, this system reduces oil waste by 5–10%—staff don’t replace oil too early (when it’s still usable) or too late (when it’s ruined). A hotel with 10 fryers reported saving 50L of oil monthly with the sensors: “Before, we changed oil on a set schedule (every 3 days) regardless of quality. Now we change it only when the sensor says so—sometimes it lasts 4 days, which adds up.”

Even without built-in sensors, AT Cooker recommends using digital oil test kits (available for purchase through their customer service) to track quality objectively. These kits are affordable ($20 for 50 tests) and provide results in 30 seconds, making them a worthwhile investment for any commercial kitchen.

8. Electric Fryers’ Consistent Heat Lowers Consumption

Electric fryers—especially induction models—provide more consistent heat distribution than gas fryers, which have hot spots (areas of higher temperature) in the tank. Hot spots cause oil to degrade faster in specific areas, even if the overall temperature seems correct. This means gas fryer users often have to replace oil earlier than necessary, as hot spots ruin parts of the oil batch.

AT Cooker’s electric induction fryers eliminate hot spots by using magnetic heating that targets the entire bottom of the tank, not just a single burner. This even heat ensures oil degrades uniformly, so the entire batch remains usable until FFA levels are high across the tank—not just in hot spots.

A comparative test by a culinary school found:

- Gas Fryer: Hot spots reached 390°F while the rest of the tank was 370°F. Oil in the hot spot area had FFA levels of 1.5% (ruined) when the rest of the tank was 0.8% (still usable). Staff had to replace the entire batch, wasting 50% of usable oil.

- AT Cooker Induction Fryer: Temperature was 370°F across the entire tank. FFA levels were 0.8% uniformly, so staff could use the oil until levels reached 1%—no wasted oil.

This consistency translates to lower consumption: electric fryer users replace oil 15–20% less frequently than gas fryer users. A fast-food chain with 20 locations switched from gas to AT Cooker’s electric fryers and reported: “We used to buy 10,000L of oil monthly—now we buy 8,500L. The consistent heat means we don’t waste oil due to hot spots.”

For kitchens transitioning from gas to electric, this is a hidden benefit: not only do electric fryers save on energy costs (90–95% efficiency vs. 45% for gas), but they also save on oil costs—doubling the return on investment.

9. Oil Turnover Rate Impacts Quality & Consumption

Oil turnover rate—the speed at which oil is used and replaced— is a key metric for commercial kitchens. A high turnover rate (frying large volumes daily) means oil is used quickly, so it doesn’t have time to degrade much. A low turnover rate (frying small volumes) means oil sits in the tank longer, degrading even with minimal use. This means two kitchens with the same fryer can have drastically different consumption rates based on turnover.

For example:

- High Turnover Kitchen: A burger chain using the 23L fryer fries 300 portions daily. Oil is used quickly, so it lasts 3 days (turnover rate = 7.6L/day). Monthly consumption: 228L.

- Low Turnover Kitchen: A café using the same 23L fryer fries 50 portions daily. Oil sits in the tank longer, degrading from idle heat, so it lasts only 4 days (turnover rate = 5.75L/day). Monthly consumption: 172L.

Wait—this seems counterintuitive: the high turnover kitchen uses more oil daily but has a similar monthly cost to the low turnover kitchen. The difference is quality: high turnover oil is always fresh, so food tastes better, while low turnover oil may taste “stale” even if it’s within replacement time.

To optimize turnover rate, AT Cooker recommends:

- For high turnover: Use larger fryers (e.g., 40L×2) to reduce refills and ensure oil is used before degradation.

- For low turnover: Use smaller fryers (e.g., 10L) to minimize the amount of oil sitting idle, and turn off the fryer between uses to reduce idle degradation.

A café in Seattle adjusted its setup: “We used a 23L fryer for 50 portions daily—oil lasted 4 days but tasted old. We switched to a 10L fryer, and oil lasts 3 days but tastes fresh. Monthly oil use dropped from 172L to 100L, and customers notice the better flavor.”

Oil turnover rate is also influenced by “topping off”—adding fresh oil to the tank instead of replacing it entirely. While topping off can extend oil life temporarily, it’s not a long-term solution: old oil will eventually contaminate the new oil, leading to faster degradation. AT Cooker advises complete oil replacement when quality drops, not just topping off.

10. Environmental Factors (Temperature, Humidity) Increase Evaporation

Environmental factors in your kitchen—like ambient temperature and humidity—can increase oil consumption by causing evaporation. Oil evaporates slowly at frying temperatures (325–375°F), and high ambient temperature (above 80°F) or humidity (above 60%) accelerates this process. Over time, evaporation can account for 5–10% of monthly oil consumption, a hidden cost many kitchens overlook.

AT Cooker’s fryers are designed to minimize evaporation with insulated tanks that reduce heat loss to the surrounding air. The 23L fryer’s tank has a 3-layer insulation system that keeps the exterior cool and the interior temperature stable, reducing evaporation by 70% compared to uninsulated fryers.

A restaurant in Florida (high humidity) tested this: “Our old uninsulated fryer lost 1L of oil daily to evaporation. The AT Cooker insulated fryer loses only 0.3L daily—saving 21L monthly.” For a 23L fryer, this adds up to $63 monthly (assuming $3/L for oil).

To further reduce evaporation:

- Keep the fryer lid closed when not in use—this traps heat and reduces exposure to humid air.

- Install exhaust fans near the fryer to remove hot, humid air from the kitchen.

- Monitor oil levels weekly—top off with fresh oil only when levels drop below the “min oil level” (marked on AT Cooker tanks) to avoid overfilling.

A bakery in Arizona (high temperature) used these tips: “We keep the fryer lid closed between batches and run an exhaust fan—evaporation dropped from 0.8L to 0.4L daily. Over a year, that’s 146L saved.”

While evaporation is unavoidable, these steps can significantly reduce its impact on oil consumption—especially in extreme climates.

11. Maintenance Practices Extend Oil Life

Proper fryer maintenance directly impacts oil consumption rate. A well-maintained fryer keeps oil clean and temperature-stable, extending oil life. A poorly maintained fryer (dirty tank, faulty heating elements) causes oil to degrade faster, increasing consumption.

AT Cooker recommends a simple maintenance routine for all commercial fryers, focused on three key areas:

1. Tank Cleaning: Clean the fryer tank weekly (or monthly for low-volume use) to remove burnt-on crumbs that can’t be filtered out. Use AT Cooker’s recommended cleaner (non-abrasive to avoid scratching the tank) and a soft brush to scrub the bottom. A dirty tank can reduce oil life by 20%—burnt crumbs release constant acids into the oil.

2. Heating Element Inspection: Check heating elements quarterly for damage (e.g., cracks, corrosion). Faulty elements cause uneven heating, leading to hot spots that degrade oil. AT Cooker’s induction coils are sealed, so they only need a wipe with a dry cloth—no water needed.

3. Seal Replacement: Replace the fryer lid seal annually (or sooner if it’s cracked). A worn seal allows heat and moisture to escape, increasing evaporation and causing temperature fluctuations. AT Cooker sells replacement seals that take 5 minutes to install.

A school cafeteria with 5 AT Cooker fryers followed this routine: “Before maintenance, we replaced oil every 3 days. After starting weekly tank cleaning and quarterly element checks, oil lasts 4 days—saving 50L monthly.”

Neglecting maintenance is costly: a diner that skipped tank cleaning for 6 months saw oil life drop from 4 days to 2 days, doubling their monthly oil cost. “We had to replace the fryer tank eventually—burnt crumbs had damaged the surface. It was cheaper to do regular maintenance than replace the tank,” said the owner.

AT Cooker provides a maintenance checklist with every fryer, and their customer service team offers free virtual training on maintenance best practices—ensuring staff know how to keep fryers in top condition.

12. Initial Oil Fill vs. Actual Consumption

It’s important to distinguish between initial oil fill capacity (the amount of oil needed to fill the fryer to the “max level” for the first time) and actual consumption (the amount of oil replaced regularly). Initial fill is a one-time cost, while consumption is a recurring expense—confusing the two can lead to budget errors.

For AT Cooker’s models:

- 10L Countertop Fryer: Initial fill = 10L (one-time cost). Actual consumption = ~1.4–2L/day (recurring).

- 23L Freestanding Fryer: Initial fill = 23L (one-time cost). Actual consumption = ~5.75–7.6L/day (recurring).

- 40L×2 Dual-Tank Fryer: Initial fill = 80L (one-time cost). Actual consumption = ~26–40L/day (recurring).

A new restaurant owner learned this distinction: “I budgeted for the initial 23L fill ($69) but forgot about monthly consumption ($516 for 172L). AT Cooker’s customer service helped me adjust my budget—now I include both initial and recurring costs.”

Actual consumption also varies with operational habits, even for the same model. For example:

- A kitchen that filters daily, maintains the fryer, and uses the auto-shutoff timer will have lower consumption than one that doesn’t.

- A kitchen that fries mostly plain foods will have lower consumption than one that fries mostly breaded foods.

- A kitchen in a cool, dry climate will have lower consumption than one in a hot, humid climate.

To estimate actual consumption for your kitchen, use AT Cooker’s “Consumption Calculator” (available on their website): input fryer model, daily usage hours, food type, and climate, and it provides a monthly consumption estimate. This tool helps new customers avoid budget surprises and plan for oil costs.

13. Oil Level Sensors Prevent Overuse & Spills

Many modern commercial fryers include oil level sensors that prevent overfilling and alert staff when oil is low. These sensors reduce oil consumption by avoiding spills (overfilled oil spills when adding food) and ensuring oil is not used below the “min level” (which causes overheating and faster degradation).

AT Cooker’s fryers have two types of oil level sensors:

1. Low Oil Sensor: Alerts staff when oil drops below the minimum safe level (marked on the tank). Running a fryer with low oil causes the heating element to overheat, which degrades remaining oil and can damage the fryer. The sensor sounds a beep and displays a “Low Oil” message on the screen—preventing this issue.

2. Overfill Sensor (High-End Models): Prevents overfilling by stopping oil flow when the tank reaches the max level. This is especially useful for new staff, who may not know the correct fill level. Overfilled oil spills during cooking, wasting oil and creating fire hazards.

A fast-food chain with high staff turnover said: “The low oil sensor has saved us from ruining oil multiple times—new staff forget to check levels, but the sensor alerts them. We used to waste 5L of oil monthly due to overheating; now we waste none.”

For kitchens without built-in sensors, AT Cooker recommends marking the “min” and “max” oil levels on the tank with a permanent marker—this simple step reduces spills and overuse by 10–15%. A café in Austin did this and reported: “We used to overfill by 1–2L monthly—now we fill to the marked line, saving $6–$12 monthly.”

Oil level sensors are a small feature but have a big impact on consumption: they eliminate preventable waste from spills and overheating, keeping oil costs in check.

14. Cost Analysis: Oil Purchase + Disposal Expenses

When calculating oil consumption costs, it’s important to include both oil purchase costs and disposal expenses—disposal is a hidden cost that can add 10–15% to total oil expenses. Commercial kitchens can’t pour used oil down the drain (it clogs pipes and violates environmental regulations), so they must hire a disposal service or recycle the oil (for biodiesel), both of which have costs.

A full cost analysis for AT Cooker’s 23L fryer (monthly consumption = 172L) illustrates this:

- Purchase Cost: 172L × $3/L = $516/month.

- Disposal Cost: 172L × $0.30/L (average disposal fee) = $51.60/month.

- Total Monthly Cost: $567.60.

To reduce disposal costs, many AT Cooker customers partner with biodiesel companies that pick up used oil for free (or even pay a small fee for it). A hotel in Miami does this: “We give our used oil to a biodiesel company—they pick it up for free, and we get a $0.10/L rebate. This cuts our disposal cost to zero and adds $17.20/month in rebates.”

AT Cooker also recommends tracking oil usage and disposal to identify inefficiencies. For example, if a fryer’s disposal volume is much higher than its purchase volume, it means oil is being wasted (e.g., spills, overfilling). A restaurant noticed this: “Our disposal volume was 20% higher than purchase volume—we found staff were spilling oil during filtration. Fixing this cut disposal costs by $10/month.”

Over time, small cost savings add up: optimizing both purchase and disposal expenses can reduce total oil costs by 15–20% annually. For a kitchen spending $6,811.20 yearly on oil ($567.60/month), this means a savings of $1,021.68–$1,362.24 annually.

Choose the Right Commercial Fryer for Your Oil Capacity & Consumption Needs

Share your daily frying volume, food type, and kitchen size—our experts will recommend an AT Cooker commercial fryer with the ideal oil capacity to minimize consumption and costs. Get a custom quote today, including initial oil fill and monthly consumption estimates.