Reducing Burn Risks: Why Commercial Induction Bratt Pans Are the Safer Choice for Institutional Kitchens

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Burns are the most common and costly injury in commercial kitchens. In high-volume institutional settings—hospitals, schools, and prisons—the risk multiplies with the scale of the equipment. Handling 100 liters of boiling soup or 50kg of searing meat creates extreme hazard zones. Traditional gas equipment, with its open flames and hot external surfaces, exacerbates these risks. The safest alternative is commercial kitchen burn prevention equipment powered by induction. At AT Cooker, our Induction Bratt Pans are engineered with “Cool-Touch” technology and automated safety locks to protect your most valuable asset: your staff.

Workplace injuries don’t just hurt employees; they hurt your bottom line through workers’ compensation claims, lost shifts, and lowered morale. When a kitchen upgrades to safe institutional cooking appliances, the reduction in accidents is immediate. The Commercial Induction Tilting Bratt Pan represents the pinnacle of safety engineering. By eliminating open flames and utilizing magnetic friction, we remove the primary sources of ignition and contact burns found in gas kitchens.

In this safety audit, we explore the 12 critical features that make induction the responsible choice for risk-averse organizations.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Eliminating the Open Flame: Removing the #1 Source of Kitchen Burns and Fires

The “Fire Triangle” requires heat, fuel, and oxygen. Gas kitchens provide all three in abundance. An open flame can ignite loose clothing, kitchen towels, or oil splatter instantly. This risk is constant and unpredictable.

Induction removes the ignition source. There is no open flame. The surface of the AT Cooker Bratt Pan generates heat only when activated by the magnetic field. This flameless operation eliminates the most common cause of catastrophic kitchen burns.

2. The “Cool-Touch” Chassis: Why Multi-Layer Insulation Prevents Contact Burns

In a gas appliance, the entire metal body heats up due to thermal conduction and waste heat. Leaning against a gas range can result in a serious contact burn.

Induction is targeted. The heat stays in the cooking pan. The chassis of the AT Cooker unit is heavily insulated and remains cool to the touch (typically below 40°C). This cool touch commercial kitchen technology protects staff working in tight quarters from accidental burns.

3. Automated Tilting Safety: Removing the Risk of Scalding from Manual Pouring

Pouring 50 liters of hot soup manually is a recipe for a scalding accident. Back injuries and splash burns are common when staff try to lift heavy pots.

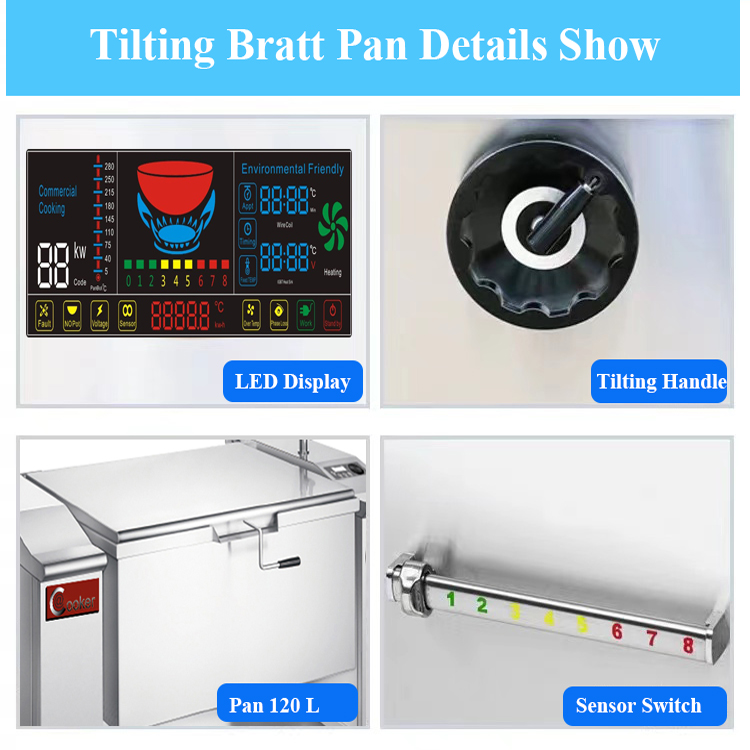

Our Bratt Pans feature a motorized tilting mechanism with a precise worm gear. You can tilt the pan with a button press, controlling the pour speed exactly. This hands-off approach removes the physical strain and splash risk from the equation.

4. Precise Temperature Limits: Preventing Dangerous Oil Flashovers and Boil-Overs

Oil fires occur when fryers overheat past the flash point (approx 300°C). Gas thermostats can drift or fail, allowing this to happen.

Digital Safety

The AT Cooker control system has a hard digital limit. If you set it to 180°C, it stays there. If the sensor detects an abnormal spike (dry burning), it cuts power in milliseconds, preventing the oil from ever reaching ignition temperature.

5. Controlled Steam Venting: How Heavy-Duty Lids Protect Staff from Sudden Bursts

Steam burns are often worse than hot water burns. Opening a lid incorrectly can release a cloud of scalding steam into a chef’s face.

Our units feature heavy-duty, counterbalanced lids with engineered steam vents. These vents direct steam away from the user during cooking. The lid mechanism holds its position safely, preventing it from slamming down on hands.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

6. The Danger of Radiant Heat: How Gas Burners Can Ignite Aprons and Towels

Radiant heat travels through the air. A gas burner running at full blast radiates heat that can dry out and ignite flammable materials nearby.

Induction produces zero radiant waste heat. The energy goes into the food. This creates a safer perimeter around the cooking station, reducing the risk of accidental ignition of aprons or towels hanging nearby.

7. Slip-and-Fall Prevention: How Precise Pouring Spouts Reduce Floor Spills

Slips are the #1 cause of worker comp claims. Spilling greasy water or oil during transfer creates a skating rink.

The AT Cooker unit features a specially designed pouring lip. It ensures a laminar flow of liquid directly into the floor trough or transfer container, eliminating splashes and drips that cause slip hazards.

8. Intelligent Sensors: Dry-Burn Protection That Shuts Down Overheating Instantly

Leaving a pan on without food is a fire risk. The metal can warp or melt.

Our smart chips detect the thermal profile of a dry pan (rapid temp rise). If the pan is empty and heating, the system triggers an “Overheat Error” and shuts down immediately. This intelligence protects the equipment and the building.

9. Ergonomic Safety: Eliminating Back Strain and Splash Risks When Handling 100L Loads

Musculoskeletal injuries from lifting are common. The Bratt Pan eliminates the need to lift heavy stock pots.

By bringing the cooking surface to a comfortable working height and utilizing the tilt function for unloading, the chef maintains a safe, upright posture. This ergonomic design reduces long-term strain and injury risk.

10. Lowering Insurance Premiums: The Financial Benefit of “Flameless” Kitchen Safety

Insurers assess risk. A kitchen with open flames and hot oil is high risk. A kitchen with flameless induction and automated safety features is low risk.

Upgrading to induction bratt pan safety features can often lead to reduced insurance premiums, adding a financial incentive to your safety upgrade.

11. The “Cold Shell” Standard: Ensuring Outer Body Temperatures Remain Below 40°C

We adhere to the “Cold Shell” standard. Through advanced insulation and airflow design, the exterior stainless steel panels of our units remain safe to touch, even when the pan inside is at 200°C.

This prevents “accidental brush” burns in tight kitchen aisles, protecting all staff members.

12. Eliminating “Chimney Fires”: Removing the Risk of Grease-Laden Flue Combustion

Gas appliances require flues that collect grease. If a flare-up happens, the flue can ignite, causing a chimney fire that spreads to the roof.

Induction has no flue. There is no combustion exhaust. By removing the chimney, you remove the chimney fire risk entirely.

| Safety Hazard | Gas Bratt Pan | AT Cooker Induction |

|---|---|---|

| Open Flame | Yes (High Risk) | None |

| Surface Temp | Hot | Cool-Touch |

| Pouring | Manual/Assist | Motorized Auto-Tilt |

| Oil Fire Risk | Medium | Ultra-Low (Digital Limit) |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Safety is the most important investment you can make. The AT Cooker Commercial Induction Bratt Pan protects your people, your building, and your business continuity.

With stock ready for immediate delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we can help you build a safer kitchen today. Visit our About Us page to consult with our safety experts.