Replace 3 Machines: How Commercial Induction Bratt Pans Save 50% Floor Space in Institutional Kitchens

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Space is the most expensive commodity in a modern institutional kitchen. Hospitals, universities, and military canteens are under pressure to produce high-volume meals in shrinking footprints. The traditional solution—buying a boiling kettle, a griddle, and a frying range—is obsolete. The solution is consolidation. By deploying AT Cooker Commercial Induction Bratt Pans (Tilting Skillets), you can replace three separate stations with one powerhouse unit. This guide explores the commercial induction bratt pan benefits that are allowing facilities to cut their kitchen footprint in half while doubling their menu versatility.

In the world of mass catering, efficiency is defined by flow. If a chef has to walk 10 feet from the boiling pan to the griddle, time is lost. If your kitchen requires three separate hoods to vent three separate machines, money is wasted. The Commercial Induction Bratt Pan is the “Swiss Army Knife” of industrial cooking. It braises, boils, fries, and grills—all in one rectangular, tilting footprint.

But versatility is only half the story. The real revolution is in the heating method. By combining the multi-functional design of a tilting skillet with the 95% energy efficiency of AT Cooker induction technology, we have created a machine that saves space, energy, and labor simultaneously. Let’s analyze how this single piece of equipment can transform your institutional catering kitchen layout.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The All-in-One Solution: Braising, Boiling, Grilling, and Frying in a Single Unit

The Bratt Pan is the transformer of the kitchen. It is a large, rectangular, tilting vessel that can do almost anything. You can use it as a fryer for schnitzel in the morning, a griddle for pancakes at lunch, and a boiling pan for soup in the evening.

By integrating AT Cooker induction technology, we add speed and precision to this versatility. The uniform heating of the induction coil turns the entire pan floor into a consistent cooking surface, eliminating the hot and cold spots common in gas skillets.

2. Calculating Square Footage Savings: Consolidating Kettles, Griddles, and Ranges

In a hospital kitchen, space is often priced at a premium. A standard setup might require a 4-burner range (900mm), a flat-top griddle (900mm), and a 100L boiling kettle (1000mm). That is nearly 3 meters of hood line.

A single commercial induction bratt pan performs all these functions in a footprint of just 1200mm. This consolidation frees up 50% of your floor space, allowing for wider aisles, more prep tables, or simply a smaller, cheaper kitchen build.

3. The Economic Impact of Reducing Ventilation Hood Length Requirements

Kitchen ventilation is expensive. Hoods cost roughly $1,000 per linear foot to install, plus the ongoing cost of makeup air. By reducing your equipment line from 3 meters to 1.2 meters, you save thousands on the hood installation alone.

Furthermore, because induction produces very little waste heat, the load on your extraction fans is lower, reducing daily electricity costs for ventilation.

4. Workflow Optimization: Minimizing Staff Movement Between Separate Cooking Stations

Efficiency is about motion. If a chef has to walk from the range to the griddle to the sink, they are wasting time. With a Bratt Pan, the chef stands in one spot.

They can sear meat, deglaze the pan, add stock, and switch to braise mode without moving their feet. This stationary workflow is less tiring and significantly faster for bulk production.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

5. Maintenance Cost Analysis: Servicing One Machine Instead of Three Distinct Appliances

Three machines mean three pilot lights, three gas connections, and three maintenance contracts. A single Bratt Pan simplifies your preventative maintenance schedule.

The AT Cooker Bratt Pan is built with a solid-state induction engine. There are no gas valves to clog or thermocouples to fail. The reduction in moving parts translates to higher uptime and lower annual service costs.

6. Energy Efficiency: Lowering Utility Bills with Direct Induction Heat Transfer

A gas griddle radiates heat constantly, even when empty. An induction Bratt Pan consumes energy only when it is actively heating the pan.

With 95% efficiency, the 25KW or 30KW induction generator heats the large rectangular pan surface evenly and instantly. There is no pre-heating hour required. This “On-Demand” capability slashes utility bills compared to keeping three gas appliances idling all day.

7. Capacity Management: Handling High-Volume Hospital Meal Service in Compact Zones

Institutions deal in volume. You need to cook 500 portions of beef stew by 11:30 AM. A standard stock pot is hard to stir and dangerous to pour.

The Bratt Pan’s wide, shallow design offers a massive surface area for browning meat (which adds flavor) before braising. You can cook 100 liters of stew in a vessel that is easy to access, stir, and monitor, improving food quality at scale.

8. Cleaning Speed: How Motorized Tilting Mechanisms Drastically Reduce Turnaround Time

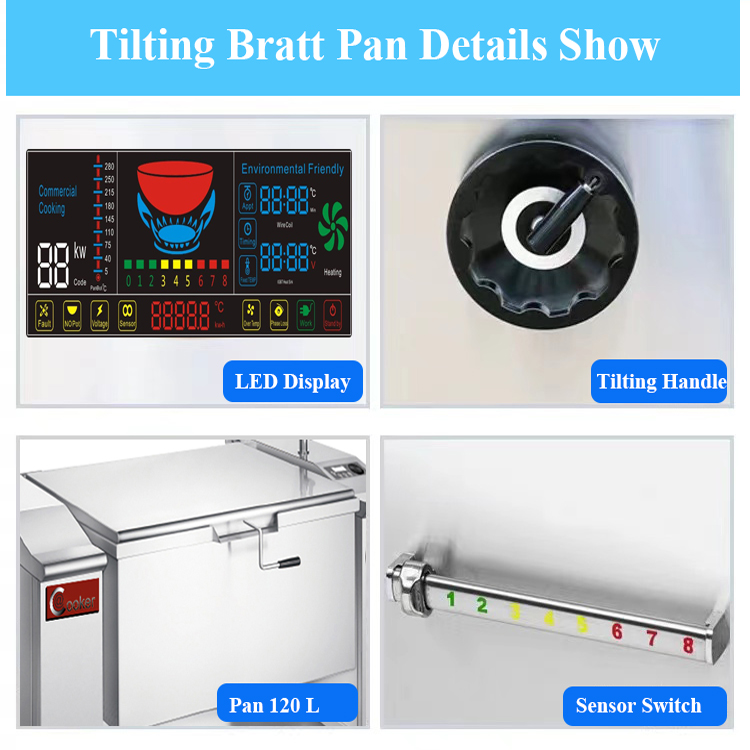

Cleaning a 100L fixed kettle is back-breaking work involving buckets and ladles. The AT Cooker Bratt Pan features a motorized tilt.

With the push of a button, the entire pan tilts forward, pouring liquids directly into a floor trough or transfer container. You can hose it down, tilt it to drain, and be ready for the next batch in 5 minutes. This speed allows for multiple menu items to be cooked in the same pan during a single shift.

9. Installation Simplicity: Reducing Plumbing and Electrical Connection Points

Installing three gas units requires a complex manifold of gas pipes. A single electric Bratt Pan requires one 3-phase electrical connection.

This simplicity reduces installation costs and makes it easier to design the kitchen layout. There are fewer points of failure and fewer potential leak sources.

10. Safety Standards: Eliminating Open Flames and Reducing Ambient Heat in Confined Spaces

Hospital and prison kitchens have strict safety codes. Open flames are a liability. The industrial braising pan efficiency of induction comes with a safety bonus: no fire.

The exterior of the unit stays cooler, reducing burn risks. The lack of combustion gases improves air quality, creating a healthier environment for staff working in confined basement kitchens.

11. Optimizing “Ping Xiao”: Maximizing Production Output Per Square Meter of Kitchen Floor

In Asia, “Ping Xiao” measures the revenue generated per square meter. The Induction Bratt Pan is the king of Ping Xiao.

By stacking vertical cooking functions (boiling/braising) with horizontal functions (grilling/frying) in one footprint, you maximize the productivity of every inch of floor space. This is essential for central kitchens located in high-rent urban areas.

12. Reducing “Labor Intensity”: How Multi-Functional Equipment Simplifies Mass Catering Operations

Moving heavy pots from a range to a sink is dangerous and tiring. With a tilting skillet, the food moves, not the chef.

This multi-functional commercial cooking equipment allows older or less physically robust staff to handle large volumes safely. It democratizes the heavy lifting of the kitchen, allowing you to utilize your labor force more effectively.

| Comparison | 3 Separate Units | AT Cooker Induction Bratt Pan |

|---|---|---|

| Footprint | 3.0 Meters | 1.2 Meters |

| Energy Source | Gas + Electric | Electric Only |

| Cleaning | 3x Effort | Auto-Tilt (Easy) |

| Ventilation | Large Hood | Small Hood |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Space saving is cost saving. By replacing three machines with one AT Cooker Commercial Induction Bratt Pan, you streamline your entire operation. It is the smartest investment for any institutional kitchen.

With stock ready for immediate delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we can help you reclaim your kitchen floor. Visit our About Us page to consult with our layout experts.