Can Busy Chinese Kitchens Really Cut Energy Bills by 50% with Commercial Induction Wok Stations?

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Chinese restaurant kitchens are some of the most energy-intensive environments in the culinary world. High-pressure “Dragon Burners” run all day, consuming vast amounts of gas to maintain the intense heat required for Wok Hei. But is this waste necessary? Data shows that switching to commercial induction wok energy efficiency can slash utility bills by half. By replacing 40% efficient gas burners with 95% efficient AT Cooker induction stations, you don’t just save money—you transform your kitchen’s profitability. Here is the financial breakdown.

The roar of a gas wok burner is the sound of money burning. In a traditional Chinese kitchen, energy costs are often the second highest expense after labor and food. The inefficiency is structural: to heat a wok with gas, you must heat the air around it. This wasted heat escapes up the hood, taking your profits with it.

Modern sustainable asian cooking equipment changes the physics of the kitchen. With 30kw induction wok running cost being significantly lower than gas equivalents due to direct energy transfer, the ROI is undeniable. In this guide, we perform a deep-dive audit into reducing chinese restaurant utility bills through electrification.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Comparing Thermal Efficiency: 95% Direct Energy Transfer vs 40% Gas Combustion

The core of the savings is physics. A gas flame loses 60% of its heat to the environment. It heats the air, the cooktop frame, and the chef, before it heats the wok. This means for every $1.00 of gas, you only get $0.40 of cooking power.

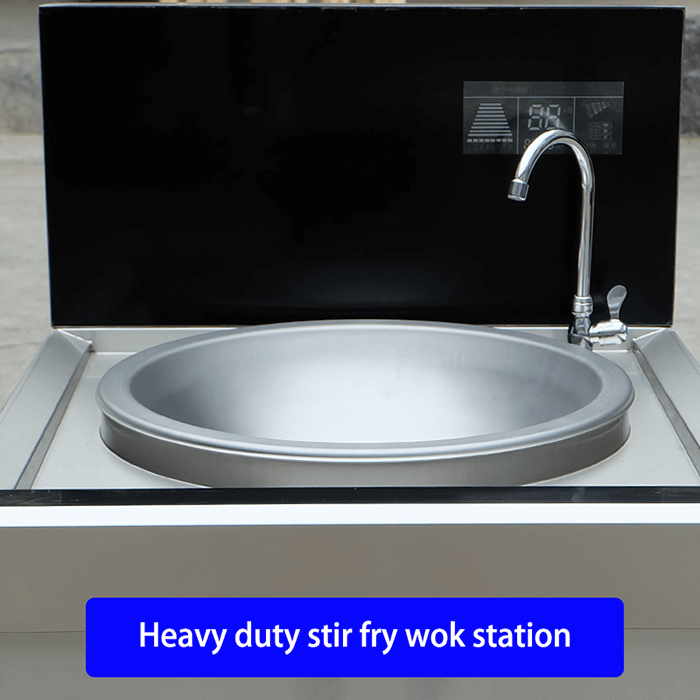

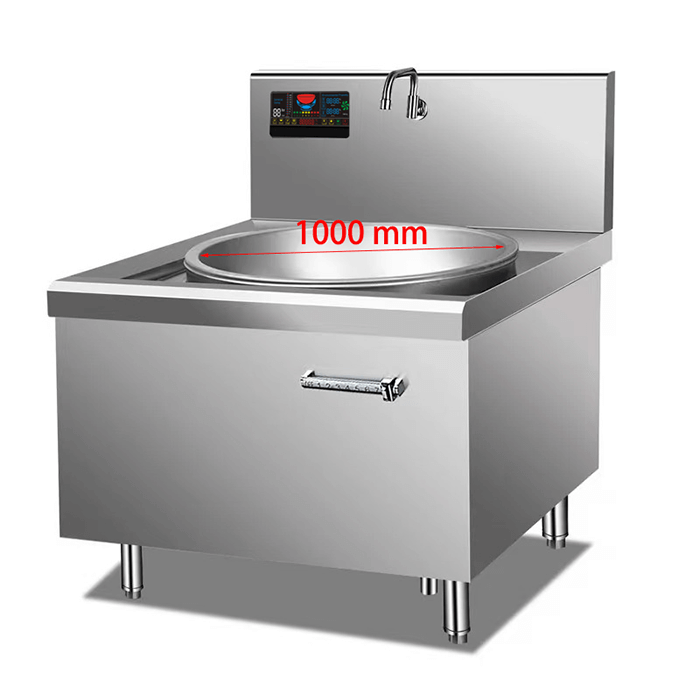

The AT Cooker Commercial Wok Station uses induction technology to generate heat directly within the metal of the wok pan. There is no open flame, no hot air rising around the sides. The efficiency is 95%. You pay for the heat you use, not the heat you waste.

2. The Hidden Cost of “Always-On” Gas Pilot Lights in High-Volume Kitchens

In a busy Chinese kitchen, gas woks are rarely turned off. The pilot lights burn 24/7, and chefs often leave main burners on “low” to avoid the delay of re-igniting. This “phantom load” adds up to hundreds of dollars a month.

Induction consumes virtually zero power in standby. When you lift the wok, the energy stops. When you put it down, it’s instant. This “On-Demand” usage model eliminates the waste of idling equipment.

3. Calculating the HVAC Bonus: Lowering AC Bills by Reducing Kitchen Ambient Heat

A gas kitchen is a sweatbox. The 60% of waste heat from gas burners puts a massive load on your air conditioning system. You pay to generate the heat (gas bill), and then you pay again to remove it (electric bill).

❄️ The Cool Kitchen Effect

Switching to induction lowers the ambient kitchen temperature by 5-10°C. This reduces the workload on your HVAC system by up to 30%, creating a hidden “Double-Dip” saving that most owners overlook.

4. Speed vs. Consumption: How Shorter Cook Times Drastically Lower Total KWh Usage

A 30KW induction wok heats faster than a 120,000 BTU gas burner. Because the heat is instant and focused, cook times are reduced.

If you can cook a stir-fry in 2 minutes instead of 3, you are running the machine for 33% less time. Over thousands of dishes a month, this reduction in “active runtime” significantly lowers your total KWh consumption.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

5. Regional Utility Rate Analysis: When Does Electricity Beat Natural Gas Prices?

Even if natural gas is cheaper per unit than electricity in your area, the efficiency gap often tips the scale. You need 2.5 units of gas to do the work of 1 unit of electricity.

Unless gas is 3x cheaper than electricity in your region, induction is almost always cheaper to operate. Plus, induction protects you from the volatility of fossil fuel prices.

6. The Financial Impact of “Pan-Lift” Auto-Cutoff Sensors on Daily Energy Draw

Wok cooking involves constant tossing. With gas, the flame burns the air while the wok is lifted. With induction, the power cuts instantly when the pan leaves the sensor range.

If a chef tosses a wok for 20% of the cooking time, induction saves that 20% of energy automatically. This micro-saving happens hundreds of times a shift, accumulating into massive annual reductions.

7. Maintenance Savings: Eliminating Gas Line Cleaning and Carbon Buildup Removal Costs

Gas nozzles clog. Pilot lights fail. Flues get greasy. Maintaining gas equipment is dirty and expensive work.

The AT Cooker unit is solid-state. There are no burners to scrub, no jets to unclog. The glass-ceramic surface wipes clean. Reducing maintenance labor and parts replacement is a direct contribution to the bottom line.

8. ROI Timeline: Calculating How Many Months to Recoup the Equipment Premium

Induction costs more upfront. But let’s look at the ROI. If you save $300/month on energy and $100/month on maintenance/HVAC, that is $4,800/year.

For most busy Chinese restaurants, the induction vs gas wok cost comparison shows a break-even point in 12-18 months. After that, the savings are pure profit.

9. Peak Demand Charges: Managing Electrical Load Spikes in High-Power Commercial Kitchens

30KW is a lot of power. To avoid peak demand charges from your utility, AT Cooker units feature “Soft Start” technology.

This ramps up the power smoothly, avoiding sudden spikes on the grid. Smart kitchen management—staggering start-up times for equipment—can further mitigate electrical demand costs.

10. Preventing “Empty Burning”: How Induction Reduces Energy Waste During Prep Lulls

Leaving a gas wok on “high” while prepping ingredients is common but wasteful. It warps the wok and burns money.

Induction requires a magnetic load to heat. If you leave an induction wok on “high” without food or water, smart sensors detect the rapid heat rise and shut it down to prevent damage and waste. This intelligence protects your wallet.

11. The Impact of Standardized “Huo Hou” Control on Reducing Over-Firing Energy Waste

Chefs often use “maximum flame” for everything, wasting energy on dishes that only need medium heat. Gas knobs are imprecise.

Induction offers digital levels (1-8). You can mandate that vegetable blanching happens at Level 6, not Level 8. This standardization prevents “Over-Firing” and ensures energy is used precisely as needed.

12. Quantifying Energy Loss Differences During High-Frequency Wok Tossing Actions

Tossing creates air gaps. With gas, the flame continues to burn full fuel while heating nothing but air. With induction, the power draw drops significantly or pauses during the toss.

In a dish that requires 50 tosses, this difference accumulates. Induction only consumes peak power when the pan is in contact, maximizing the efficiency of every movement.

| Cost Factor | Gas Wok Station | AT Cooker Induction |

|---|---|---|

| Thermal Efficiency | 40% | 95% |

| Idle Cost | High (Pilots) | Zero |

| HVAC Load | Massive | Minimal |

| Maintenance | High | Low |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Can you cut energy bills by 50%? Yes. The data is clear: AT Cooker Commercial Induction Wok Stations stop the waste associated with gas cooking. They are cleaner, cooler, and significantly cheaper to run.

With stock ready for immediate delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, you can start saving money on your very next utility bill. Visit our About Us page to request a detailed cost-benefit analysis.