Zero Recovery Time: How Commercial Induction Woks Dominate the Lunch Rush

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

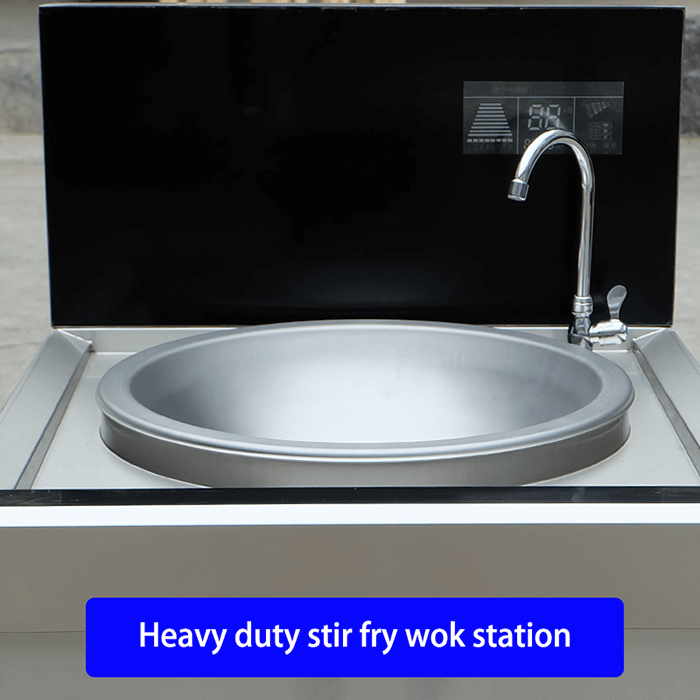

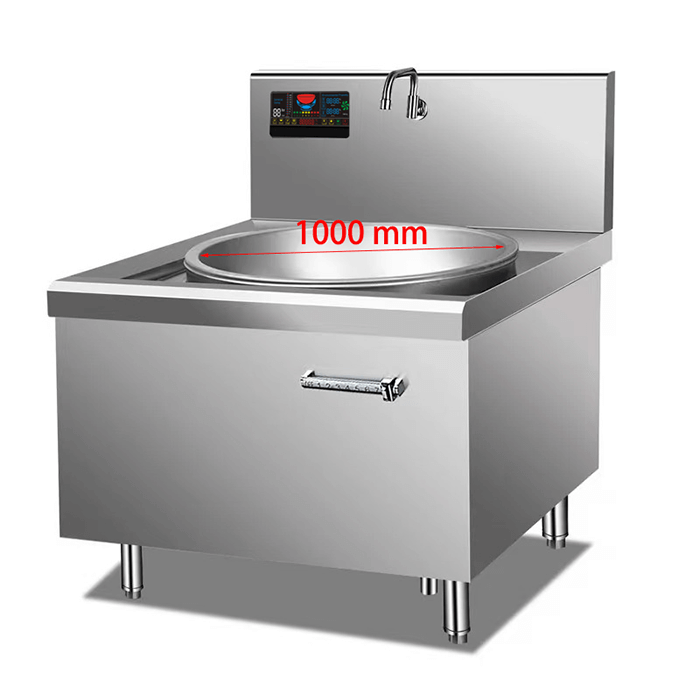

AT Cooker Executive Insight: The lunch rush is a war against time. Every second a chef waits for a pan to reheat is a second that a customer waits for food. In high-volume Asian kitchens, “Thermal Lag” is the enemy. Traditional gas burners struggle to recover heat after cold ingredients are added. The solution is the fast heat recovery induction wok. With AT Cooker commercial induction stations, we deliver “Zero Recovery Time”—instant heat restoration that keeps the line moving and table turnover high.

Speed is the defining characteristic of a profitable lunch service. When orders for Pad Thai, Fried Rice, and Stir-Fry pile up, the equipment becomes the bottleneck. A gas burner might output a lot of BTUs, but it wastes time heating the air and the metal grate before it heats the food.

Modern commercial kitchen lunch rush efficiency demands better. By utilizing 30KW high-frequency magnetic drivers, AT Cooker Commercial Wok Stations achieve a thermal response that is physically impossible with gas. This capability allows chefs to cook continuously without pausing for the pan to catch up.

In this performance guide, we analyze the physics of heat recovery and how induction dominance translates to revenue.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Defining “Zero Recovery Time”: The Holy Grail of High-Volume Kitchens

In commercial cooking, “recovery time” is the delay between when you drop cold food into a pan and when the temperature returns to the optimal cooking zone. “Zero Recovery Time” means the heat source is so powerful and responsive that this drop is negligible.

For a lunch rush, this is the Holy Grail. It means you can chain-smoke stir-frys without waiting for the wok to heat back up. The AT Cooker 30KW induction system achieves this by dumping massive energy into the steel instantly, obliterating thermal lag.

2. Thermodynamics 101: Why Gas Burners Lag Behind Magnetic Friction Heating

Gas is limited by physics. The flame heats the air, then the wok, then the food. When you add cold meat, the steel cools down. The flame has to work hard to reheat the mass of the wok before it can heat the food.

Induction uses magnetic friction. The heat is generated inside the wok metal. When the sensor detects a 1°C drop, the inverter responds in milliseconds, pushing energy directly into the food. This induction vs gas thermal recovery rate difference is why induction feels “instant.”

3. Eliminating the “Soggy Vegetable” Syndrome Caused by Pan Temperature Drops

Soggy vegetables happen when the wok temperature drops below 140°C. Instead of searing (Maillard reaction), the vegetables steam in their own juices.

With fast heat recovery induction wok technology, the temperature never dips into the “steaming zone.” Even when you dump 1kg of cold broccoli, the 30KW power maintains the sear, ensuring crisp, bright green results every time.

4. How Instant Heat Restoration Directly Boosts Lunch Hour Table Turnover Rates

If you save 30 seconds per dish because you don’t have to wait for the wok to reheat, and you serve 60 dishes an hour, you save 30 minutes of production time.

That is 30 minutes of extra revenue. Faster food means faster eating, which means increasing restaurant table turnover. Your kitchen speed directly dictates your profit ceiling during the rush.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

5. The Impact of Adding Cold Ingredients on Wok Surface Temperature Stability

Thermal shock is real. Adding cold marinade or meat acts like a heat sink. In gas cooking, chefs often crank the flame to maximum before adding ingredients to compensate.

With AT Cooker induction, the system compensates automatically. You don’t need to “pre-game” the heat. The unit reacts to the cold load by surging power, stabilizing the surface temperature instantly.

6. Energy Cost Analysis: The Expense of Idling Gas Burners vs. On-Demand Power

To avoid recovery lag, gas chefs leave burners on full blast all day. This burns thousands of dollars in fuel annually.

Induction’s “Zero Recovery” means you can turn the wok off (or to standby) between orders. When a ticket prints, you turn it on, and it’s ready in 3 seconds. This On-Demand model slashes energy waste.

7. Reducing Guest Wait Times: Shrinking the Gap Between Order and Service

Customers judge you on speed. If a stir-fry takes 8 minutes instead of 5 because the chef is waiting for the wok to heat up, the customer notices.

By removing the thermal bottleneck, you tighten the gap between order and service. This improves customer satisfaction and reduces negative reviews about “slow service.”

8. Chef Workflow Optimization: Removing the “Wait-to-Reheat” Bottleneck

Rhythm is key. A chef wants to toss, plate, wipe, and toss again. Waiting 20 seconds for a gas wok to regain heat breaks this rhythm.

With high speed commercial cooking equipment, the chef sets the pace, not the stove. This fluid workflow reduces frustration and increases output per man-hour.

9. Ensuring Consistent “Wok Hei” for Both the First and Last Order of the Shift

Consistency builds brands. Wok Hei shouldn’t fade during a rush. Gas pressure can drop when all burners are on, reducing heat.

Induction voltage is regulated. The 30KW output is constant. The first customer at 11:00 AM gets the same smoky flavor as the last customer at 2:30 PM.

10. The “Chao Niu He” Test: Maintaining Constant 200°C+ for Rice Noodle Integrity

Beef Chow Fun (Chao Niu He) is the ultimate test. Rice noodles break if they stick; they stick if the wok isn’t hot enough.

The AT Cooker unit maintains the critical 200°C+ temperature needed to sear the beef and noodles simultaneously without breakage, passing the toughest test in Cantonese cooking.

11. Overcoming the “Thermal Inertia” of Traditional Iron Woks with High-Frequency Drivers

Iron is heavy. It resists temperature change. High-frequency magnetic drivers vibrate the iron molecules so fast that they overcome this inertia instantly.

This allows a heavy commercial wok to behave with the agility of a lightweight pan, giving chefs the best of both worlds: heat retention and heat responsiveness.

12. Selecting the Right Power Rating (15KW vs 30KW) for Continuous Batch Cooking

Not every kitchen needs 30KW. For light sauté, 15KW is enough. But for continuous stir fry capability during a lunch rush, 30KW is the standard.

| Application | Recommended Power | Recovery Speed |

|---|---|---|

| A La Carte / Light Sauté | 12KW – 15KW | Fast (< 5s) |

| High Volume / Wok Hei | 20KW – 25KW | Instant (< 2s) |

| Heavy Batch / Canteen | 30KW+ | Zero Lag |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Zero Recovery Time is the competitive advantage your kitchen needs. By eliminating the lag of gas, you unlock higher volume, better quality, and lower costs. The AT Cooker Commercial Wok Station is built to dominate the lunch rush.

With stock ready for fast delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we can help you upgrade your speed today. Visit our About Us page to learn more.