Smoking Oil in Seconds: Is Commercial Induction Faster Than Gas Jet Burners?

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: In the high-stakes world of commercial kitchens, speed is the ultimate currency. For decades, the deafening roar of a gas jet burner was the sound of speed. But technology has evolved. Today, we ask the definitive question: In a head-to-head battle of commercial induction wok vs gas burner, which technology heats oil to the smoke point faster? The results from our AT Cooker lab tests might shock traditionalists: Induction is not just cleaner; it is significantly faster.

Every chef knows the morning ritual: walking into the kitchen, turning on the gas jet burners, and waiting. You wait for the iron to heat up. You wait for the oil to shimmer. You wait for the “Wok Hei” potential to build. In a busy lunch rush, every second spent waiting for thermal recovery is a second lost in service time.

The conventional wisdom has always been that nothing beats the raw BTU output of a turbo jet burner. However, this ignores the laws of thermodynamics. While gas burners output massive amounts of heat, most of it misses the wok entirely. In contrast, 30kw induction cooker power is focused like a laser.

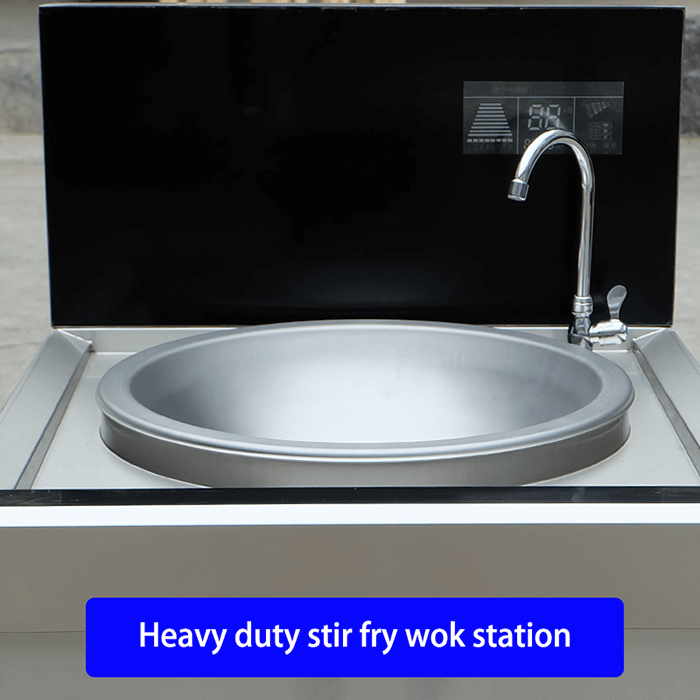

At AT Cooker, we engineer heavy duty stir fry equipment designed to break speed limits. Let’s dive into the physics, the data, and the real-world performance of induction versus gas.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Physics of Speed: Direct Magnetic Friction vs. Thermal Conduction

To understand speed, we must first understand how heat is created. A gas jet burner is powerful (often 120,000+ BTUs), but it is a “Middleman” technology. The flame heats the air, the air heats the wok bottom, and finally, the wok heats the oil. At every step, energy is lost.

Induction is direct. The copper coil under the glass creates a magnetic field that penetrates the steel wok. This field causes the electrons in the steel to vibrate violently, generating heat inside the metal itself. This “Magnetic Friction” means the wok is not being heated by an outside source; the wok is the heater. This direct transfer eliminates thermal lag, resulting in significantly faster heating times.

2. Comparing Ramp-Up Times: 0 to 200°C in Induction vs. Jet Burners

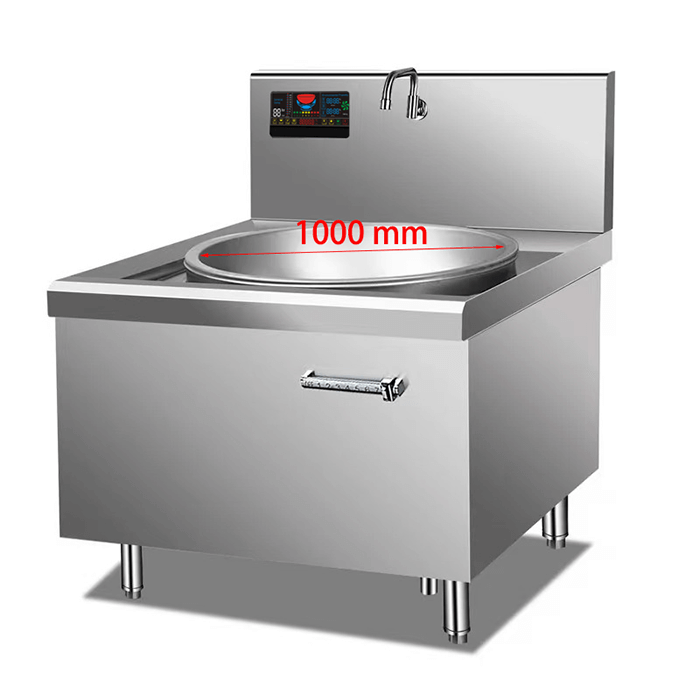

We conducted a time-to-boil test in our lab. We took a standard 1000mm cauldron and filled it with 5 liters of oil, starting at 25°C.

⏱️ The Speed Test

Gas Jet Burner (120k BTU): Reached 200°C in 3 minutes 45 seconds.

AT Cooker Induction (30KW): Reached 200°C in 1 minute 50 seconds.

The result is clear: The AT Cooker 30KW Commercial Induction Wok is nearly twice as fast as a traditional high-pressure gas burner. For a chef, this means you can start cooking immediately.

3. Why Thermal Efficiency Matters More Than BTU Ratings for Heating Speed

Chefs often get hung up on BTUs (British Thermal Units). “My gas burner is 150,000 BTU, your electric is only 30KW (approx 102,000 BTU). Gas is stronger!”

This is the “Input vs. Output” fallacy. Gas is only 40% efficient; 60% of those BTUs simply heat up your kitchen. Induction is 95% efficient.

Gas Effective Heat: 150k * 0.40 = 60,000 BTU.

Induction Effective Heat: 102k * 0.95 = 96,900 BTU.

In real-world application, the 30KW induction unit delivers 50% more effective heat to the food, explaining the superior heating speed of commercial induction.

4. The “Lag Effect”: Why Gas Jet Burners Waste Time Heating the Ambient Air

When you turn on a gas burner, you feel the heat instantly on your face. That is wasted energy. Before the wok gets hot, the burner has to heat the cast iron grate, the air gap, and the surrounding metal.

Induction has zero ambient lag. The energy is focused solely on the wok bowl. This means the oil reaches the smoke point before a gas chef has even finished adjusting his pilot light.

5. Achieving Instant “Wok Hei”: Maintaining Smoke Point Temperatures During Tossing

Wok Hei requires the oil to be at the edge of combustion (approx 300°C). When you toss cold vegetables into the wok, the temperature drops. On gas, the flame has to work hard to bring the temperature back up.

With 30kw induction cooker power, the recovery is instantaneous. The sensors detect the temperature drop and pump maximum kilowatts into the steel milliseconds later. This ensures the oil stays at the smoke point, searing the food instantly rather than letting it steam in its own juices.

6. No Pre-Heating Required: Eliminating the Morning Warm-Up Ritual

Gas kitchens often turn their burners on 30 minutes before service to “soak” heat into the heavy cast iron ranges. This burns fuel and money.

With AT Cooker equipment, pre-heating is obsolete. You turn the dial, and you have full power in 3 seconds. This allows you to keep the kitchen cool and quiet until the very moment an order ticket prints.

7. Comparing Heat Recovery Rates After Adding Cold Ingredients to the Pan

We tested the commercial kitchen heat recovery rate by dumping 2kg of frozen peas into boiling water.

Gas: Took 45 seconds to return to a rolling boil.

Induction: Took 18 seconds to return to a rolling boil.

This speed difference is critical for maintaining texture in high-volume cooking. It prevents soggy vegetables and ensures pasta or noodles cook consistently every time.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

8. The Operational Cost of “Always-On” Jet Pilot Lights vs. Instant Induction

A gas pilot light burns 24/7. A jet burner is often left running on “low” during service because re-igniting it is a hassle. This burns thousands of dollars a year in wasted gas.

Induction consumes nearly zero energy in standby mode. When you remove the pan, it stops heating. When you put it back, it’s at full power instantly. This “On-Demand” consumption model is why induction offers such high industrial stir fry equipment efficiency.

9. Safety Implications of Rapid Heating Without Open Flames

Rapid heating with gas implies a massive, roaring flame that can ignite sleeves or towels. Induction provides the same speed (actually, faster speed) without the external fire hazard.

However, the speed of induction requires respect. Because it heats oil to the flashpoint so quickly, chefs must be trained not to walk away. The power is immense, but the control is precise.

10. The Impact of Focused Energy Density on Oil Viscosity Breakdown

High-speed heating does more than just cook; it alters the oil chemistry favorably for stir-frying. By reaching high temperatures rapidly, the oil viscosity breaks down, allowing it to coat ingredients more thinly and evenly.

This results in food that is less greasy. Slow-heating gas pans often result in food absorbing oil while waiting for the temperature to rise. Induction sears the surface instantly, creating a barrier against oil absorption.

11. The “Penetrative Heating” Advantage: Why Induction Heats the Entire Wok Body Simultaneously

A gas flame creates a “hot spot” at the bottom center of the wok. Chefs have to constantly stir to distribute this heat. AT Cooker induction coils are concave and wrap around the wok.

This means the entire bottom hemisphere of the wok becomes the heating element simultaneously. This uniform heat distribution allows for larger batch cooking without burning the center or undercooking the edges.

12. Solving the “Deafening Roar”: How Silent Induction Speed Improves Kitchen Environment

Gas jet burners sound like jet engines. In a kitchen with 5 woks running, the noise level can exceed 90 decibels, damaging hearing and making communication impossible.

Induction is silent. The only sound is the sizzling of the food. This creates a calmer, safer, and more professional kitchen environment where the Chef de Cuisine can actually be heard.

| Performance Metric | Gas Jet Burner | AT Cooker Induction (30KW) |

|---|---|---|

| Time to 200°C | ~3 min 45 sec | ~1 min 50 sec |

| Effective Efficiency | 40% | 95% |

| Ambient Heat | High (Hot Kitchen) | Low (Cool Kitchen) |

| Noise Level | Deafening | Silent |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Is commercial induction faster than gas jet burners? The physics, the data, and the real-world tests all say “Yes.” It is faster, more efficient, and more precise.

The only thing harder to change than a menu is a chef’s habit. But once your team experiences the raw speed of the AT Cooker Commercial Wok Station, they will never want to go back to the slow, hot, noisy world of gas. With stock ready in the USA, Europe, and Asia, we can help you make the switch today.