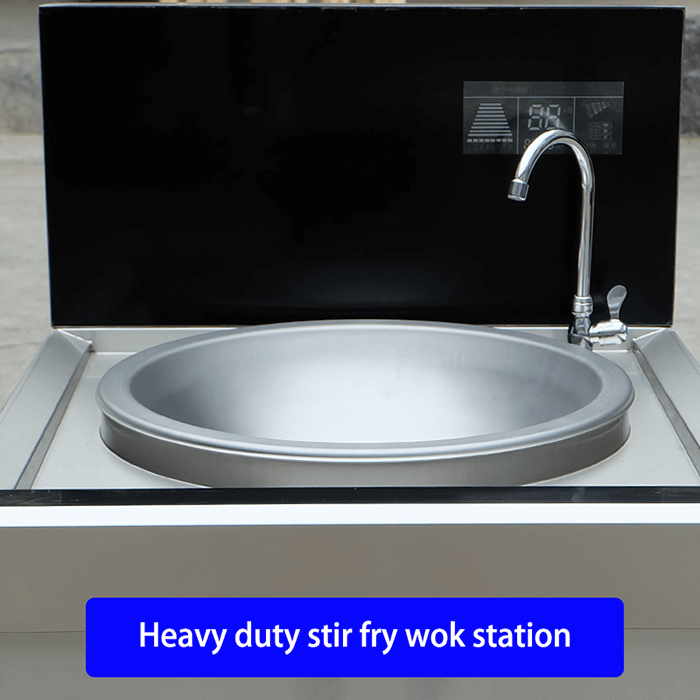

Zero Lag Performance: Can Commercial Induction Woks Match the Aggressive Speed of Gas Jet Burners?

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

For decades, the Asian kitchen has been dominated by one sound: the roar of the atmospheric gas jet burner. Chefs love the visible aggression of fire. It feels fast, it feels powerful, and it demands respect. When commercial induction wok heating speed is mentioned, many veterans are skeptical. “It’s too slow,” they say. “It can’t keep up with my ladle.”

This perception is outdated. Modern 30kw induction wok power equivalent technology has not only caught up to gas—it has overtaken it. At AT Cooker, we engineer equipment that offers “Zero Lag” performance. By eliminating the thermal barriers of traditional heating, we provide instant heat response technology that matches the most aggressive stir-fry techniques beat for beat. In this technical breakdown, we pit physics against fire to prove why induction is the new king of speed.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Physics of Speed: Why Magnetic Friction Heats Faster Than Thermal Conduction

To understand speed, you must understand heat transfer. Gas cooking is “Thermal Conduction.” The flame heats the air, the air heats the bottom of the pan, and the pan heats the food. It’s a chain reaction with three steps. Each step loses energy and time.

Induction is “Magnetic Friction.” The copper coil generates a magnetic field that penetrates the steel of the wok. The iron molecules inside the wok vibrate millions of times per second, generating heat directly within the metal. There is no middleman. The heat doesn’t travel to the pan; the heat is created by the pan. This direct generation creates zero lag induction cooking performance that gas physically cannot replicate.

2. Comparing Ramp-Up Times: Reaching Smoke Point in Seconds vs Minutes

In a head-to-head test, a 100,000 BTU gas burner takes about 60-90 seconds to bring a wok of oil to the smoke point (230°C). An AT Cooker 30KW induction wok does it in 15-20 seconds.

3. The “Lag” Myth: Analyzing Sensor Response Times During Rapid Pan Tossing

The myth of lag comes from early residential induction units that would shut off for 2-3 seconds every time the pan was lifted. This ruined the rhythm of stir-frying.

Commercial units are different. Our high speed commercial stir fry equipment uses advanced sensors with a polling rate of milliseconds. We know you are tossing. The system is designed to “ride” the toss, maintaining a ready-state so that the nanosecond the pan touches the glass, full power is restored. There is no waiting. There is no lag.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

4. Thermal Recovery Benchmark: Maintaining 200°C When Adding Cold Proteins

The real test of a wok burner isn’t getting hot; it’s staying hot. When you dump 1kg of marinated beef into the wok, the temperature crashes. With gas, the flame fights to reheat the cooled pan metal from the outside.

With induction vs gas wok recovery time, the difference is stark. The induction coil forces energy into the steel regardless of its temperature. The recovery curve is virtually vertical. This means your beef sears instantly instead of stewing in its own juices, preserving texture and flavor.

5. BTU vs KW: Why 30KW Induction Outperforms 100,000 BTU Jet Burners

Chefs are used to BTUs. A typical jet burner is 100,000 to 120,000 BTU. A 30KW induction unit converts to roughly 102,000 BTU. They look similar on paper, but this is misleading.

Gas is ~40% efficient. That means of your 100,000 BTU, only 40,000 BTU actually heats the food; the rest heats the kitchen. Induction is ~95% efficient. Of your 102,000 BTU, 97,000 BTU goes into the food. In effective cooking power, a 30KW induction wok is more than double the strength of a standard jet burner.

6. Miao Hui Technology: Millisecond Power Restoration for Seamless Chef Rhythm

We call our instant-response algorithm “Miao Hui” (Second Return). It ensures that the power cycle is synchronized with the chef’s movements.

Unlike mechanical gas valves that have a delay in fuel flow, our digital inverters manage electricity at the speed of light. This millisecond power restoration ensures that the equipment becomes an extension of the chef’s hand, never breaking the flow of service.

7. The Impact of Pan Material: How Composite Steel Reacts Faster Than Cast Iron

Traditional cast iron woks are great for holding heat, but they are slow to change temperature. For induction, we recommend 409/430 ferritic stainless steel.

This material is magnetically reactive and allows for lightning-fast temperature adjustments. If you need to drop the heat to simmer a sauce, it happens instantly. If you need to blast it for the final sear, it happens instantly. The combination of the right metal and the right machine gives you ultimate control.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

8. Eliminating the Pre-Heat Ritual: The Operational Speed of Instant-On Cooking

Gas kitchens start their day by lighting the pilots and blasting the woks for 20 minutes to “soak” the heat into the cast iron rings. This is wasted time and fuel.

With AT Cooker induction, you walk in, turn the knob, and cook. There is no pre-heat ritual. This operational speed allows you to start service faster and shut down faster, optimizing your labor hours.

9. Digital Precision: How Fast Processors Eliminate the Delay of Mechanical Valves

When you turn a gas valve, a mechanical linkage opens a hole for gas to flow. It’s analog and imprecise.

Our units use 32-bit Infineon processors. When you adjust the power knob, the change in the magnetic field is calculated and executed digitally. There is no mechanical delay. The response is linear, precise, and immediate, giving the chef fine-grained control over the thermal environment.

10. Sustained Aggression: Does Cooling Efficiency Affect Long-Term Speed Stability?

Some induction units overheat and throttle down power after an hour of heavy use. This is “Thermal Throttling,” and it kills speed.

AT Cooker designs commercial kitchen thermal performance for marathon runners, not sprinters. Our dual-channel cooling capability ensures the IGBTs and coil stay cool even when the wok is white-hot. This means the speed you get at 11:00 AM is the same speed you get at 9:00 PM peak service.

11. The Role of Concave Coil Design in Delivering Immediate Surround Heat

Gas flames wrap around the wok. Flat induction coils only heat the bottom. We solve this with “Deep Concave” coils that mirror the shape of the wok.

This design ensures that magnetic energy is projected into the sides of the wok, not just the base. This “surround heat” mimics the thermal envelope of a gas burner, ensuring that food tossed up the sides continues to cook evenly and aggressively.

12. Voltage Stability: Ensuring Grid Fluctuations Don’t Throttle Heating Speed

In a commercial zone, voltage can fluctuate. A drop in voltage usually means a drop in power.

Our mainboards feature broad voltage adaptability. Even if your grid fluctuates, our capacitors stabilize the output to the coil. This ensures that your heating speed remains consistent, protecting your kitchen’s rhythm from external electrical variables.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts: The Future is Faster

Nostalgia for gas is understandable, but the data is undeniable. With superior efficiency, instant response, and zero lag recovery, AT Cooker commercial induction woks don’t just match gas—they leave it in the dust. It’s time to upgrade your speed.

Want to Feel the Speed?

Contact us to schedule a live demo or video call and see our 30KW units in action.