The Secret to Perfect Even Heating: Why Concave Design Matters in Commercial Induction Woks

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Asian cuisine is defined by the wok. Unlike Western pans, the wok is curved for a reason—it facilitates the rapid movement and tossing of ingredients. However, the most common complaint about electric woks is “hot spots” at the center and cold zones on the sides. The solution lies in the concave commercial induction wok design. At AT Cooker, we have spent 15 years mastering even heating commercial cooking equipment. In this guide, we analyze the physics of curvature and why a 360-degree magnetic field is the only way to achieve authentic results.

In a traditional gas kitchen, the flames lick up the sides of the wok, creating a wide heating zone. Flat induction hobs, designed for flat-bottom pans, fail miserably when paired with a traditional round-bottom wok. They only heat the tiny point where the metal touches the glass, leading to burnt centers and raw edges. This is why round bottom wok induction technology was developed.

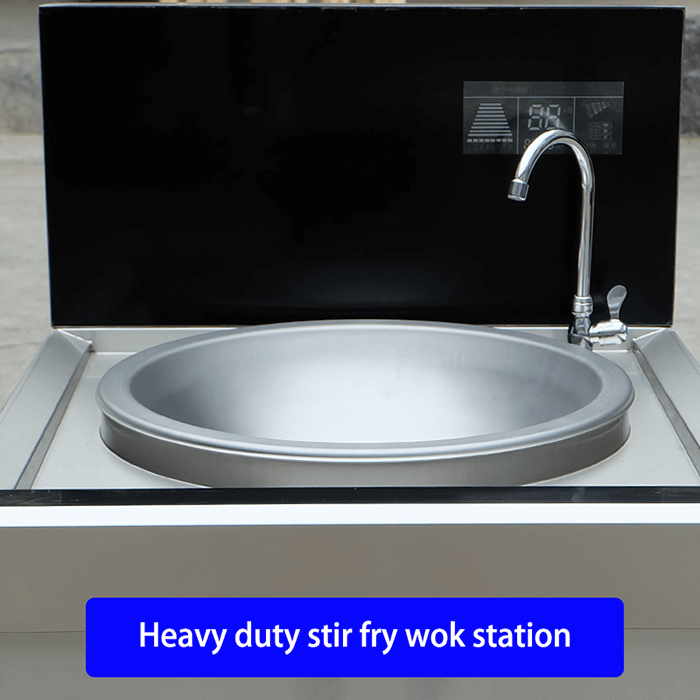

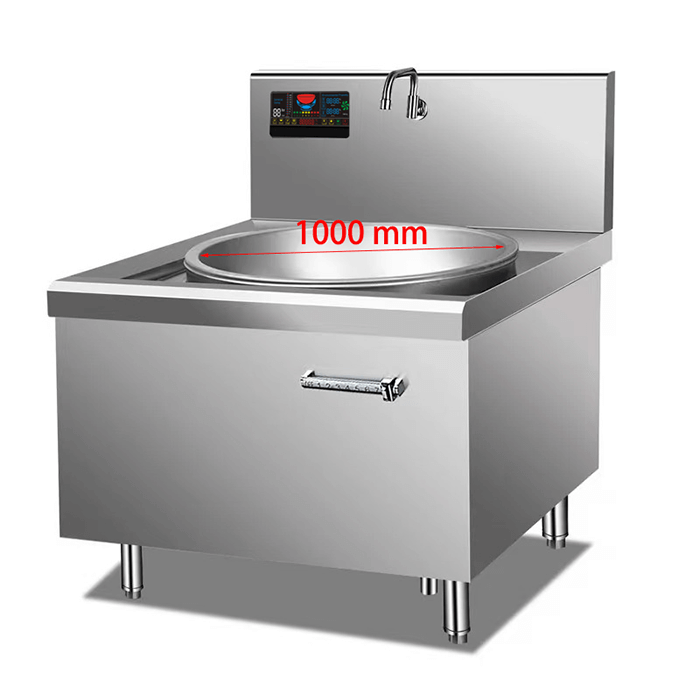

The AT Cooker Commercial Wok Station utilizes a concave glass-ceramic bowl that mirrors the shape of the pan. This allows the induction coil underneath to sit just millimeters away from the entire lower hemisphere of the wok. This engineering feat delivers heavy duty asian cooking technology that rivals the heat distribution of a 150,000 BTU gas burner.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Physics of Curvature: How Concave Coils Perfectly Match Round-Bottom Woks

Heat transfer efficiency is a function of distance. In induction, the magnetic field strength drops off exponentially as the distance between the coil and the metal pan increases. For a round-bottom wok, a flat induction hob is a disaster—only the tiny apex of the curve receives heat.

The concave commercial induction wok design solves this by curving the copper induction coil into a high-precision bowl shape. This engineering ensures that the gap remains constant across the entire surface of the wok. This “Perfect Match” means that every part of the steel wok is energized simultaneously, enabling even heating commercial cooking equipment performance at an industrial scale.

2. Eliminating the “Flat-Bottom Limit”: Heating the Sides for True Stir-Frying

Authentic stir-frying requires “climbing the walls.” When a chef tosses ingredients, they travel up the hot sides of the wok to aerate and sear. If the sides are cold, the food loses thermal momentum.

Induction hobs with flat surfaces force chefs to use flat-bottomed pans, which limit the tossing motion and trap steam, resulting in soggy food. By using round bottom wok induction technology, we restore the chef’s ability to utilize the vertical space of the pan, maintaining heat throughout the entire tossing arc.

3. Magnetic Field Distribution: Ensuring Uniform Energy Density Across the Entire Pan Surface

A major secret of the AT Cooker wok station is the density of the coil windings. In standard units, the center of the coil is often hotter than the edges. Our concave coils are wound to provide uniform induction coil magnetic field coverage.

This uniform energy density means that if you place a cold load of meat in the center, and cold vegetables on the side, both will sear at the same rate. This is the hallmark of heavy duty asian cooking technology designed for high-volume commercial kitchens.

4. The “Surround Heating” Effect: Simulating Traditional Gas Flame Coverage Without Fire

Gas flames are chaotic but effective because they wrap around the vessel. Induction is often criticized for being too directional. Our concave design creates a “Surround Heating” effect that mimics the gas flame envelope.

The magnetic field doesn’t just hit the bottom; it surrounds the lower third of the wok. This creates a thermal “reservoir” of heat that maintains the wok temperature even when cold ingredients are added, providing a seamless transition for chefs moving from gas to electric.

5. Preventing Localized Scorching: Why Flat Induction Burns but Concave Sears Evenly

When all the power of a 30KW unit is focused on a 5-inch circle (the contact point of a round wok on a flat hob), scorching is inevitable. The metal in that spot superheats and warps, while the rest of the pan stays cool.

The concave design spreads that 30KW over 200 square inches of surface area. This reduces the energy density per square inch while increasing the total thermal output. The result is a perfect sear across the entire batch, preventing hot spots in stir fry production.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

6. The Importance of Gap Consistency Between Wok Steel and Internal Copper Coil

If the gap between the glass and the coil is inconsistent, you get uneven heating. Our manufacturing process uses laser-aligned mounting brackets for the internal coil assembly.

This ensures that the benefits of curved glass ceramic are fully realized. By maintaining a perfect 3mm gap between the coil and the glass across the entire curve, we ensure that every unit performs identically, recipe after recipe.

7. Material Stress Analysis: Why Curved Glass Ceramic Handles Heavy Wok Impact Better

A flat sheet of glass is vulnerable to bending stress. An arch (concave shape) is one of the strongest structures in engineering.

When a chef slams a 10kg wok onto the cooktop, the concave shape distributes the impact force outwards toward the stainless steel chassis. This structural advantage contributes to a longer heavy duty induction cooktop lifespan, especially in high-stress canteens or army kitchens.

8. Optimizing the “Wok Hei” Zone: Where Maximum Heat Concentration Occurs in the Curve

Wok Hei requires oil to reach its smoke point (approx 300°C) instantly. In a concave induction unit, the “Energy Ring”—the area of highest magnetic flux—is positioned exactly where the oil pools at the bottom of the curve.

This allows for immediate oil vaporization. When food is tossed through this superheated zone, you achieve that authentic smoky flavor that defines premium Asian stir-fry.

9. Sensor Accuracy: How Concave Designs Improve Real-Time Temperature Feedback Loops

Temperature control on induction relies on a sensor (NTC) touching the glass. In flat designs, the pan might lift or tilt, losing contact with the sensor and giving false readings.

In a concave nest, gravity keeps the wok centered and in constant contact with the sensor area. This improves the accuracy of the 8 power levels, allowing chefs to manage “Huo Hou” (heat control) with digital precision.

10. Oil Pooling Dynamics: How Gravity and Uniform Heat Distribution Work Together

In a curved wok, oil naturally pools at the bottom. If the heat is only at the bottom, the oil gets too hot while the sides stay cold. Concave induction heats the sides, ensuring that as you toss the food, the oil and ingredients are hitting a uniformly hot surface.

This synergy between gravity and magnetic field geometry is the “Secret Sauce” to achieving a crispy texture on vegetables and a deep sear on proteins without burning the aromatics.

11. Energy Transfer Efficiency: Reducing Magnetic Leakage at the Pan Edges

Flat induction units lose a significant amount of magnetic energy to the air when used with curved pans (Magnetic Leakage). This is a waste of electricity.

The concave bowl acts as a magnetic “trap.” Because the metal pan sits deep within the coil’s field, the energy transfer efficiency remains at 90% – 95%. This is why our units can reach cooking temperatures faster than any gas jet burner on the market.

12. Ergonomic Advantages: How the Concave Nest Stabilizes Heavy Woks During Agitation

Stir-frying at scale involves woks weighing up to 5kg plus ingredients. On a flat stove, the pan slides everywhere. The concave “nest” of the AT Cooker unit provides lateral stability.

The wok stays centered naturally. This reduces the physical effort required by the chef to control the pan, leading to improving kitchen ergonomics and reducing staff fatigue during high-volume shifts.

| Design Feature | Flat Induction Hob | AT Cooker Concave Design |

|---|---|---|

| Heat Distribution | Center Only (Hot Spot) | Full Surface (360 Degree) |

| Wok Compatibility | Flat Bottom Only | Authentic Round Bottom |

| Wok Hei Potential | Low (Low Temp Sides) | High (Simulates Gas Flame) |

| Energy Efficiency | ~70% (Magnetic Leakage) | ~95% (Perfect Coupling) |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

The secret to perfect even heating is not more power; it is better geometry. The concave commercial induction wok design is the only way to deliver the speed and flavor of a traditional Asian kitchen in a modern, electric environment.

With stock ready for immediate delivery in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, AT Cooker is your partner in kitchen modernization. Don’t settle for flat performance. Upgrade to the curve. Visit our About Us page to learn more.