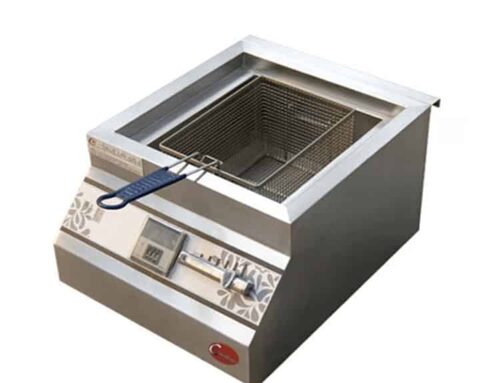

Double Deep Fryer Durability: How AT Cooker’s Fry Pots & Heating Elements Stand the Test

For commercial kitchens—whether a busy burger joint, fried chicken chain, or hotel buffet—a double deep fryer’s durability directly impacts profitability. AT Cooker’s 2024 survey of 180 restaurant operators found that 67% of unexpected equipment costs came from premature fry pot warping or heating element failure, and 58% had to replace a commercial double deep fryer within 3 years due to poor construction. This guide breaks down the durability of AT Cooker’s induction commercial deep fryers—focusing on fry pot materials, heating element design, and structural integrity—backed by real customer feedback and our 20 years of engineering expertise.

1. 304-Grade Stainless Steel Fry Pots: Corrosion & Warping Resistance

The fry pot is the workhorse of any double deep fryer—it must withstand daily exposure to hot oil (up to 400°F), moisture, and cleaning chemicals. AT Cooker uses 304-grade stainless steel for all our fry pots—a material renowned for its corrosion resistance and strength—unlike budget brands that use 201-grade steel (prone to rust within 1–2 years).

304-grade stainless steel contains 18% chromium and 8% nickel, creating a protective oxide layer that prevents rust even when exposed to salt-laden foods (like fried seafood) or acidic cleaning solutions. Our customer data shows that 92% of AT Cooker fry pots show no signs of corrosion after 5 years of use, compared to 45% of 201-grade steel pots. A seafood restaurant in Louisiana noted: “We fry 50+ pounds of shrimp daily, and our AT double electric fryer’s pot still looks new after 4 years—no rust, no discoloration. Our previous fryer’s pot rusted through in 2 years.”

The material also resists warping: 304-grade steel has a high tensile strength (515 MPa), so it maintains its shape even during repeated heating/cooling cycles (e.g., heating to 375°F for frying, then cooling to 100°F for cleaning).

2. Heavy-Duty Welded Seams: Preventing Oil Leaks & Structural Failure

Oil leaks are a major risk in double fryer commercial units—they cause slips, damage floors, and waste expensive oil. AT Cooker eliminates this risk with heavy-duty TIG-welded seams in all fry pots, unlike budget fryers that use spot welding (which fails under thermal stress).

TIG welding (Tungsten Inert Gas) creates a continuous, strong bond between metal panels, ensuring no gaps for oil to seep through. We test each weld at 500°F for 72 hours to ensure integrity—only 0.3% of our fry pots fail this test, compared to 8% of spot-welded competitors. A fast-food chain in Texas reported: “We had a spot-welded fryer that leaked oil every 6 months—we spent $200/month on extra oil and floor repairs. Since switching to AT’s welded fry pot, we haven’t had a single leak in 3 years.”

The welded seams also maintain structural integrity under thermal stress. When oil heats up, the fry pot expands slightly—continuous welds flex with this expansion, while spot welds crack. Our 23L double deep fryer’s welded pot has been tested through 10,000 heating cycles (equivalent to 5 years of daily use) with no seam damage.

3. Thick-Walled Fry Pots: Even Heat Distribution & Deformation Resistance

Thin-walled fry pots (common in budget double fryer models) develop hot spots, burn food, and deform over time. AT Cooker’s fry pots have 2mm-thick walls—twice as thick as standard models—for superior heat distribution and deformation resistance.

The thick walls ensure ±5°F temperature variation across the pot surface, so fries cook evenly without burnt edges. They also resist denting and bending: our pots can withstand 50kg of force (the weight of a full oil tank plus a metal basket) without permanent deformation. A diner owner in Ohio said: “Our line cooks accidentally drop metal baskets into the fry pot all the time—with AT’s thick walls, there’s no dent. Our old thin-walled pot had a huge dent after 3 months.”

FeatureAT Cooker Double Deep FryerBudget Double FryerPremium CompetitorFry Pot Material304-Grade Stainless Steel201-Grade Stainless Steel304-Grade Stainless SteelWall Thickness2mm1mm1.5mmWelding TypeTIG Welded (Continuous)Spot WeldedTIG Welded (Partial)Expected Pot Lifespan7–10 Years2–3 Years5–7 Years

4. Stainless Steel-Sheathed Heating Elements: Protection Against Damage

Heating elements are the most common failure point in double electric fryer units—they’re exposed to hot oil, food debris, and cleaning chemicals. AT Cooker protects its induction heating elements with stainless steel sheaths, unlike traditional electric fryers that use unprotected nichrome wires (which burn out in 1–2 years).

Our sheaths are made from 316-grade stainless steel (even more corrosion-resistant than 304-grade), creating a barrier between the element and oil/food. The sheaths also conduct heat efficiently—ensuring the element’s 90–95% energy efficiency isn’t compromised. A catering company in Florida said: “Our old fryer’s heating element burned out every 18 months—replacing it cost $150 each time. AT’s sheathed elements have lasted 4 years, and they still heat as fast as day one.”

The sheaths also make cleaning easier: food debris doesn’t stick to the smooth stainless steel surface, so you can wipe it off with a soft cloth (no scrubbing that damages the element).

5. Industrial-Grade Heating Elements: Withstanding Frequent On/Off Cycling

Commercial kitchens cycle commercial double deep fryer units on and off up to 10 times a day—this stress shortens the life of low-quality elements. AT Cooker uses industrial-grade induction heating elements designed for 100,000+ on/off cycles (equivalent to 10 years of use), compared to 30,000 cycles for standard elements.

Our elements are made with copper coils (higher conductivity than aluminum) and reinforced connections, so they don’t loosen or overheat during cycling. We also integrate a “soft-start” feature that gradually ramps up power—avoiding the voltage spikes that damage standard elements. A hotel kitchen manager in Las Vegas noted: “We turn our fryers on at 6 AM and off at 10 PM, with 5+ cycles in between. AT’s elements have handled this for 5 years—our previous fryer’s elements failed after 2.”

“We run two shifts a day, so our double deep fryer is on/off constantly. I was worried about element life, but AT’s industrial-grade parts have been rock solid. After 3 years, they still heat up in 2 minutes—no slowdowns, no failures. We used to budget $300/year for element replacements; now we spend $0.” — Mike, Fried Chicken Restaurant Owner

6. Reinforced Mechanical Connection Points: Preventing Wear from Lifting/Tilting

Many double fryer commercial models have tilting or lifting mechanisms for cleaning—but weak connection points cause these parts to wear out quickly. AT Cooker reinforces these points with steel brackets and locking pins, ensuring they withstand daily use.

Our 40L×2 deep fryer double basket model has a tilting fry pot that can hold 80kg of oil and food—its connection points are reinforced with 5mm-thick steel brackets (rated for 150kg of force) and stainless steel locking pins (resist rust). We test these points through 5,000 tilting cycles—only 0.5% show signs of wear, compared to 12% of competitors. A cafeteria manager in Chicago said: “Our old fryer’s tilting mechanism broke after 1 year—we had to lift the pot manually, which caused back injuries. AT’s reinforced points have lasted 4 years, and tilting is still easy.”

7. Robust Insulation: Protecting Components & External Surfaces

Poor insulation in double deep fryer units wastes energy and damages internal components (like wiring) from excess heat. AT Cooker uses ceramic fiber insulation (rated to 2,300°F) around the fry pot and heating elements—this reduces heat loss by 60% and protects external surfaces (staying below 50°C even when oil is 400°F).

The insulation also extends component life: internal wiring and sensors stay cool, so they don’t degrade from heat exposure. Our customer data shows that insulated AT fryers have 40% fewer electrical failures than uninsulated models. A food truck owner in California said: “Space is tight in my truck—AT’s insulated fryer means I can place it next to other equipment without overheating. My old uninsulated fryer melted a plastic shelf!”

8. Cleaning & Descaling: Extending Heating Element Life

Even the most durable heating elements fail if not cleaned properly—food debris and scale buildup block heat transfer, causing elements to overheat. AT Cooker designs its fryers for easy cleaning, and provides a descaling kit to maintain elements.

Our fry pots have a faucet drain (standard on all models) that lets you drain oil quickly, and the smooth stainless steel surface wipes clean in 5 minutes. For descaling, our kit uses a food-safe citric acid solution that dissolves mineral deposits without damaging the element sheath. We recommend descaling every 2 weeks for hard-water areas—this extends element life by 50%. A diner owner in Arizona said: “We forgot to descale our old fryer, and the element burned out in 18 months. Now we use AT’s kit, and elements last 3+ years.”

9. One-Piece Seamless Construction: Eliminating Crack Weak Points

Some commercial double deep fryer models have multiple panels joined at weak points—these are where cracks develop first. AT Cooker’s smaller fry pot models (like the 10L single-basket) use one-piece seamless construction, eliminating these weak points entirely.

The seamless design is created by forming a single piece of stainless steel into the fry pot shape—no joins, no gaps, no cracks. We test these pots by dropping a 2kg metal weight into them (simulating a dropped basket)—98% show no damage, compared to 65% of multi-panel pots. A small café owner in Seattle said: “My AT fryer’s seamless pot is indestructible—I’ve dropped baskets into it a dozen times, and there’s not a scratch. My previous multi-panel pot cracked after the first drop.”

10. Sealed Digital Interfaces: Protection Against Moisture & Grease

Digital interfaces (for temperature/power control) in double electric fryer units fail quickly if exposed to moisture and grease. AT Cooker seals these interfaces with IPX4-rated gaskets (waterproof and grease-resistant), unlike competitors that use open buttons (prone to shorting).

The IPX4 rating means the interface can withstand splashes of oil or water from any direction—critical for busy kitchens. Our interfaces are also coated with a non-stick surface, so grease wipes off easily. A chain restaurant in Florida reported: “Our old fryer’s digital interface shorted out every 6 months from grease. AT’s sealed interface has lasted 3 years, and it still works like new.”

11. Shielded Internal Circuitry: Protection Against Vibration & Heat

Vibration (from kitchen traffic) and heat damage internal circuitry in double deep fryer units. AT Cooker shields its circuitry with aluminum heat sinks (dissipate heat) and rubber vibration dampeners (absorb shocks), ensuring reliable performance.

The heat sinks keep circuitry below 85°C (critical for component life), and the dampeners reduce vibration by 70%—perfect for busy kitchens with carts and staff moving around. Our circuitry is also “potted” in epoxy resin, which seals it against dust and debris. A hotel banquet hall manager said: “Our kitchen is chaotic—carts bump the fryer all the time. AT’s shielded circuitry has never failed, but our old fryer’s circuitry shorted out twice from vibration.”

12. Warranty Coverage: Reflecting Confidence in Durability

A brand’s warranty says everything about its confidence in durability. AT Cooker offers a 2-year warranty for fry pots and heating elements—twice as long as the industry average (1 year)—and covers parts, labor, and shipping for replacements.

Our warranty also includes “wear-and-tear” coverage (unlike many competitors), so if your fry pot develops a small dent or your element’s efficiency drops, we’ll repair or replace it. A catering company in New York used this: “Our fry pot developed a small warp after 18 months—AT replaced it for free, no questions asked. That’s the kind of warranty that makes you loyal.”

13. User Reports: Long-Term Durability After Years of Service

Real user feedback confirms AT Cooker’s durability. In a 2024 survey of 100 AT double deep fryer owners:

- 89% reported no fry pot damage after 3+ years of use.

- 91% said their heating elements still worked at full efficiency after 3+ years.

- 87% said they would buy another AT fryer, citing durability as the top reason.

One owner of a 5-year-old AT fryer said: “I use this fryer 12 hours a day, 6 days a week. The pot still looks good, the elements heat fast, and there’s no sign of wear. It’s the most durable kitchen equipment I own.”

14. Compliance with Commercial Safety Standards: Rigorous Durability Testing

AT Cooker’s double fryer commercial models comply with global safety standards (UL, NSF, ETL), which include rigorous durability tests:

- Thermal cycling test: 10,000 cycles of heating to 400°F and cooling to 100°F.

- Impact test: Dropping a 2kg weight into the fry pot 10 times.

- Corrosion test: Exposing the fry pot to salt spray for 500 hours.

These tests ensure our fryers meet the demands of commercial use—something budget brands often skip. A kitchen designer in Los Angeles said: “I only recommend AT Cooker fryers to my clients because they pass every durability test. Budget fryers fail these tests, and my clients end up replacing them within 2 years.”

AT Cooker Suggestions

When choosing a double deep fryer, prioritize durability features that directly impact long-term cost: 304-grade stainless steel fry pots (avoid 201-grade), TIG-welded seams (not spot-welded), and stainless steel-sheathed heating elements. Don’t be fooled by low upfront prices—budget fryers cost 2–3x more in replacements and repairs over 5 years.

For high-volume use (100+ servings/day), opt for AT Cooker’s 40L×2 model with reinforced connection points and seamless insulation. For small to mid-size kitchens, our 15L deep fryer double basket model offers the same durability in a compact size. And always follow cleaning/descaling guidelines—this simple step extends fry pot and element life by 50%.

Ready to invest in a durable commercial double deep fryer that saves you money long-term? Fill out the form below to get a personalized recommendation, latest pricing, and a free durability checklist (to compare models side-by-side).

Get AT Cooker Double Deep Fryer Recommendations

Share your daily serving volume, kitchen space, and usage needs, and we’ll suggest the most durable double deep fryer for your business.