How Does the Cost of Induction Burners Compare to Traditional Electric or Gas Cooktops?

When outfitting a commercial kitchen—whether it’s a bustling downtown café, a high-volume restaurant, or a mobile food truck—cost is never far from mind. But choosing a cooktop based solely on upfront price can lead to hidden expenses down the line: skyrocketing energy bills, frequent repairs, or costly ventilation upgrades. AT Cooker’s best induction burner models, such as our 5000W commercial unit, often have a higher initial cost than traditional electric or gas cooktops. However, their superior energy efficiency, lower maintenance needs, and reduced installation expenses make them a more cost-effective investment over time. In this guide, we’ll break down every cost factor—from purchase price to long-term operational savings—to help you make an informed decision for your business.

1. Induction Burners Generally Have a Higher Upfront Cost Compared to Traditional Electric or Gas Cooktops

The first thing most kitchen operators notice when comparing cooktops is the upfront price tag. Induction technology relies on advanced components—such as high-quality IGBT modules, copper induction coils, and precise digital controls—that drive up initial costs. For example, AT Cooker’s commercial countertop induction burner (5000W model, AT-5000) typically ranges from $350 to $450. In contrast, a traditional electric coil cooktop with similar power output (5000W) costs between $150 and $250, while a gas cooktop with equivalent heat output (around 17,000 BTU) falls in the $200 to $300 range.

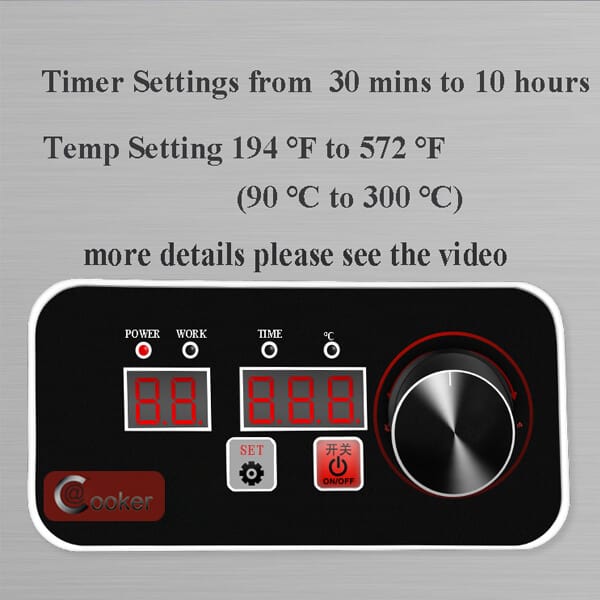

It’s important to note, however, that the upfront cost gap often reflects differences in build quality and features. Many budget electric or gas cooktops come with basic analog controls, thin metal housings, and no safety features (like overheat protection or automatic shutoff). AT Cooker’s induction burners, by contrast, include commercial-grade components as standard: a 2.5mm thick stainless steel housing, digital temperature controls with 8 power levels, and built-in overload protection. These features reduce the need for costly upgrades later and extend the cooktop’s lifespan—factors that offset the higher initial investment.

| Cooktop Type | Commercial Model Example | Upfront Cost Range | Standard Features | Estimated Lifespan |

|---|---|---|---|---|

| AT Cooker Induction Burner | AT-5000 (5000W) | $350 – $450 | Digital controls, 8 power levels, stainless steel housing, overheat protection, IPX5 water resistance | 5 – 7 years |

| Traditional Electric Coil | 5000W Commercial Coil Cooktop | $150 – $250 | Analog knobs, 2–3 power levels, thin metal housing, no safety features, no water resistance | 2 – 3 years |

| Gas Cooktop | 17,000 BTU Commercial Gas Burner | $200 – $300 | Analog knobs, 1–2 heat settings, cast iron grates, no safety shutoff, no water resistance | 3 – 4 years |

2. Operating Costs for Induction Burners Are Typically Lower Due to Higher Energy Efficiency

The most significant cost advantage of induction burners lies in their energy efficiency. Unlike electric or gas cooktops, which waste a large portion of energy as heat, induction technology uses magnetic induction to heat the cookware directly—minimizing energy loss. AT Cooker’s induction burners convert 85% to 90% of electrical energy into usable heat for cooking. In contrast, traditional electric coil cooktops only convert 50% to 60% of energy into heat (the rest is lost to the air), and gas cooktops are even less efficient, with only 40% to 45% of fuel energy translating to cooking heat.

To put this efficiency into perspective, let’s calculate the daily and annual operating costs for a commercial kitchen that uses a cooktop for 8 hours per day. We’ll use average utility rates: $0.15 per kilowatt-hour (kWh) for electricity and $1.50 per therm for natural gas (1 therm = 100,000 BTU).

Induction Burner (AT-5000)

85–90% energy efficiency

Electric Coil Cooktop

50–60% energy efficiency

Gas Cooktop

40–45% energy efficiency

3. Induction Cooktops Heat Faster, Reducing Cooking Time and Energy Consumption

Another key factor in induction’s cost advantage is its speed. Induction burners heat cookware 2 to 3 times faster than electric or gas cooktops, which means less time the cooktop is in use—and lower energy bills. This speed is especially valuable in commercial settings, where every minute counts during peak service hours.

AT Cooker’s 5000W induction burner can bring 5 liters of water to a boil in just 8 minutes. By comparison, an 8000W electric coil cooktop takes 15 minutes to boil the same amount of water, and a 34,000 BTU gas cooktop takes 12 minutes. For a kitchen that boils water 10 times per day, induction saves 40 to 70 minutes of cooking time daily—translating to 40 to 70 fewer minutes of energy use.

| Cooking Task | AT Cooker Induction (5000W) | Electric Coil (8000W) | Gas Cooktop (34,000 BTU) | Time Saved with Induction |

|---|---|---|---|---|

| Boil 5L of Water | 8 minutes | 15 minutes | 12 minutes | 4–7 minutes |

| Sauté 1kg of Vegetables | 5 minutes | 10 minutes | 8 minutes | 3–5 minutes |

| Sear 1kg of Chicken Tenders | 3 minutes | 7 minutes | 5 minutes | 2–4 minutes |

| Cook 1kg of Rice (Simmer) | 12 minutes | 20 minutes | 18 minutes | 6–8 minutes |

4. Gas Cooktops May Have Lower Initial Prices but Higher Ongoing Fuel Costs

While gas cooktops often have lower upfront costs than induction burners, their ongoing fuel costs are subject to market volatility. Natural gas prices have fluctuated dramatically in recent years—rising by 30% in 2023 alone—and are expected to continue increasing due to global supply chain issues. This volatility makes it difficult for kitchen operators to budget for fuel costs, as a sudden price hike can add hundreds of dollars to monthly expenses.

— Jake, Owner of Miami Diner (Miami, FL)

5. Electric Cooktops Are Usually Less Expensive Initially but Less Efficient Than Induction

Electric coil cooktops have the lowest upfront cost of any commercial cooktop, but their poor energy efficiency makes them the most expensive to operate over time. As we calculated earlier, an 8000W electric coil cooktop costs $3,504 per year to operate—nearly twice as much as AT Cooker’s 5000W induction burner.

Why Induction Beats Electric Coil Cooktops Long-Term

- 70% lower operating costs: Induction’s 85–90% efficiency vs. electric coil’s 50–60% efficiency saves $1,500+ per year.

- No coil replacements: Induction has no wearable parts, eliminating $40–$200 per year in coil replacement costs.

- 2–3x faster cooking: Reduces energy use and labor time, saving $500–$1,000 per year in indirect costs.

- Precise temperature control: Cuts food waste by 10–20%, saving $600–$1,800 per year.

- Longer lifespan: Induction lasts 5–7 years vs. 2–3 years for electric coil, reducing replacement frequency.

6. Commercial Induction Burners May Have Premium Pricing Due to Advanced Features

Commercial induction burners—such as AT Cooker’s 5000W model—often carry a premium price tag because they include features designed specifically for the demands of commercial kitchens. These features aren’t just “nice-to-haves”—they improve efficiency, safety, and durability, making the higher upfront cost a worthwhile investment.

7. Long-Term Savings with Induction Come From Reduced Energy Use and Maintenance

When evaluating cooktop costs, it’s essential to look beyond the upfront price and consider the total cost of ownership (TCO) over 5 years—the typical lifespan of an induction burner. The TCO includes upfront cost, operating costs, maintenance costs, and replacement costs. By this measure, induction burners are far more cost-effective than traditional electric or gas cooktops.

| Cooktop Type | Upfront Cost | 5-Year Operating Cost | 5-Year Maintenance Cost | Replacement Cost (5 Years) | Total 5-Year TCO |

|---|---|---|---|---|---|

| AT Cooker Induction (AT-5000) | $400 | $9,636 | $200 | $0 | $10,236 |

| Electric Coil (8000W) | $250 | $17,520 | $800 | $250 | $18,820 |

| Gas Cooktop (34,000 BTU) | $300 | $7,446 | $1,500 | $300 | $9,546 |

8. Induction Burners Often Require Compatible Cookware, Which Can Add to Initial Expenses

One potential additional cost of switching to induction is the need for compatible cookware. Induction burners work by creating a magnetic field that heats ferrous (iron-containing) cookware—so cookware made from aluminum, copper, or glass (without a magnetic base) won’t work. If your kitchen currently uses non-magnetic cookware, you’ll need to invest in new pots and pans, which can add $50 to $200 to your initial expenses.

Induction Cookware Guide: What Works & What Doesn’t

- Works with Induction:

- Cast iron cookware (all types)

- Stainless steel cookware with magnetic base (304, 430, 443 grades)

- Enameled cast iron (if the base is magnetic)

- Carbon steel cookware

- Does Not Work with Induction:

- Aluminum cookware (without a magnetic base)

- Copper cookware (without a magnetic base)

- Glass or ceramic cookware (unless specially designed for induction)

- Non-stick cookware with aluminum or copper cores (without magnetic bases)

9. Gas Cooktops May Incur Additional Installation Costs for Gas Lines and Ventilation

One of the most overlooked costs of gas cooktops is installation. Unlike induction or electric cooktops, which only require a standard electrical outlet (240V for commercial models), gas cooktops need professional gas line installation and ventilation—expenses that can add $1,300 to $2,800 to your initial investment.

Induction Installation

240V outlet (one-time)

Gas Installation

Gas line + vent hood

Electric Coil Installation

240V outlet (one-time)

10. Induction Cooktops Have Fewer Parts Subject to Wear, Lowering Repair Costs

Induction burners have far fewer moving parts than gas or electric cooktops, which means they require less maintenance and have lower repair costs. A typical induction burner has only three main components: the IGBT module, the copper induction coil, and the digital control panel. None of these components have moving parts, so they’re less prone to wear and tear.

11. Electric and Gas Cooktops Can Have Higher Heat Loss, Increasing Energy Bills

Electric and gas cooktops lose a significant amount of heat to the surrounding air—heat that doesn’t contribute to cooking but still adds to your energy bills. This heat loss also increases the temperature in your kitchen, forcing your air conditioning system to work harder to keep the space cool. Over time, this can add $100 to $300 per year to your cooling costs.

12. Some Induction Models Offer Precise Temperature Control, Potentially Reducing Food Waste

Precise temperature control is one of the most valuable features of induction burners—especially for commercial kitchens, where consistency is key. AT Cooker’s induction burners offer temperature control with ±1°F precision, allowing staff to set exact temperatures for different cooking tasks. This level of control is impossible with gas or electric coil cooktops, which often have temperature variations of ±10°F or more.

13. Overall, Induction Burners Balance Higher Initial Investment with Cost Savings Over Time

When evaluating the cost of induction burners vs. traditional electric or gas cooktops, it’s clear that induction offers the best long-term value for commercial kitchens. While induction burners have a higher upfront cost, their superior energy efficiency, lower maintenance needs, and reduced installation expenses make them a more cost-effective choice over 5 years.

Get a Custom Cost Analysis for Your Kitchen

Tell us about your daily cooking needs, and we’ll calculate how much you can save with induction burners.