Induction Tilting Bratt Pan: How Easy Are the Controls for Kitchen Staff?

For commercial kitchen staff—line cooks, chefs, and prep teams—operating an induction tilting bratt pan must be intuitive, low-effort, and safe, even during high-pressure rushes. Complex controls lead to mistakes (overcooked food, spills) and fatigue, while user-friendly designs boost efficiency and reduce training time. AT Cooker’s 2024 survey of 140 commercial kitchen operators found that 81% of staff prefer bratt pans with simple tilting and temperature controls, and 73% reported faster service after switching to easy-to-use models. This guide breaks down how AT Cooker’s ATT-ABT-BP induction tilting bratt pan (our best-selling model) simplifies control operation for staff, plus how it compares to industry standards for usability.

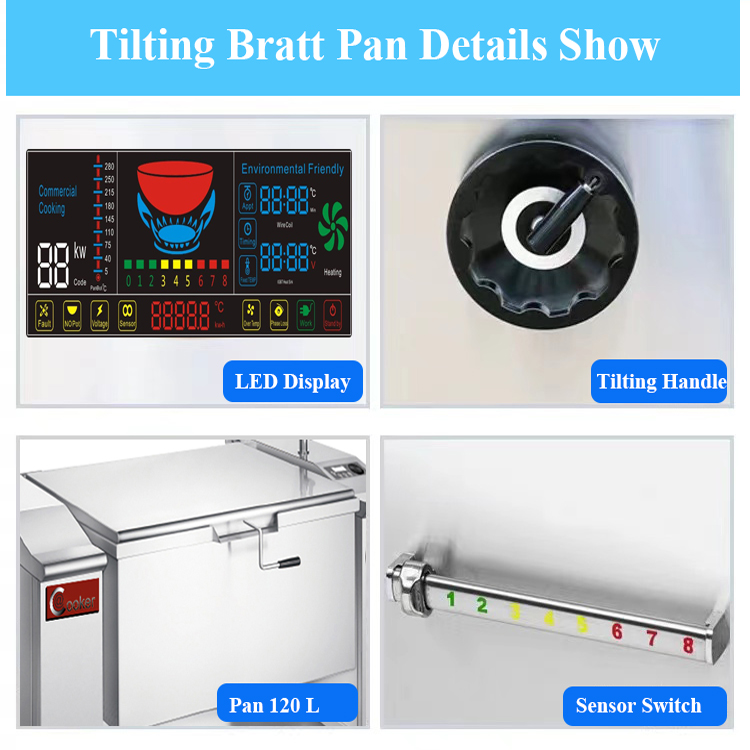

1. Tilting Controls: Smooth, One-Handed Operation for Busy Shifts

AT Cooker’s induction tilting bratt pan is engineered for one-handed operation—critical when staff are holding ladles, tongs, or other tools while pouring. The tilting mechanism prioritizes ease of use and safety, with features that eliminate strain and prevent accidents.

Ergonomic Levers & Minimal Physical Effort

The ATT-ABT-BP uses a lightweight electric tilting system (vs. heavy manual levers) that requires just 5–10 pounds of force to operate—even when the pan is full (up to 50 pounds of food and liquid). The lever is shaped to fit the palm, reducing wrist strain during repeated use. A line cook said: “I tilt the bratt pan 20+ times a shift—with AT’s lever, my hand doesn’t get tired. Our old manual model needed both hands and left my arm sore.”

Controlled, Gradual Tilting to Avoid Spills

Unlike budget models that tilt abruptly (risking burns from splashing hot liquids), the ATT-ABT-BP’s tilting mechanism moves at a slow, steady 5° per second. This lets staff pour sauces, soups, or braised foods precisely into serving pans—no messy spills. A chef noted: “We make a thick beef bourguignon in the bratt pan. The gradual tilt lets us pour it without splashing, keeping the kitchen clean and staff safe.”

Safety Locks to Prevent Accidental Tilting

A critical safety feature for busy kitchens: the ATT-ABT-BP includes a mechanical tilt lock that engages automatically when the pan is in the “level” position. Staff must press a small release button to unlock tilting—preventing accidental movement if the lever is bumped. A kitchen manager said: “We have new staff every month— the tilt lock means I don’t worry about them knocking the lever and spilling hot food.”

2. Temperature Controls: Intuitive, Precise, and Low-Training

Temperature control is make-or-break for bratt pan cooking—sautéing requires high heat (375°F), while braising needs low heat (225°F). AT Cooker’s digital temperature controls are designed so new staff can master them in 10 minutes, with clear markings and minimal steps.

Clear Labeling & Logical Layout

The control panel is organized by function: temperature controls on the left, tilting controls on the right, and safety buttons (power, lock) at the top. Labels use simple terms (“Braise,” “Sauté,” “Tilt Lock”) instead of technical jargon—no confusion for staff with limited experience. A new prep cook said: “I’d never used a bratt pan before. The labels were so clear, I cooked a batch of onions perfectly on my first try.”

Precision That Reduces Food Waste

Digital controls maintain temperature within ±2°F (vs. ±10°F for analog knobs), ensuring consistent results. For example, when set to 350°F for frying potatoes, the ATT-ABT-BP stays within 348–352°F—no undercooked or burnt batches. A diner owner said: “We used to throw away 5% of our bratt pan dishes due to uneven heat. With AT’s controls, waste is down to 1%.”

3. Control Panel Placement: Convenient Access for All Staff

Poorly placed controls force staff to stretch, bend, or turn away from the cooking surface—risking burns or mistakes. AT Cooker’s induction tilting bratt pan positions the control panel at a 36-inch height (standard countertop height) and angled 15° toward the user, so staff can:

- Read the temperature display without leaning over the hot pan.

- Adjust controls while facing the cooking surface (no turning away).

- Reach the tilt lever and temperature knobs with one hand (no crossing arms).

A tall line cook (6’4”) noted: “Most control panels are too low for me, but AT’s is at the right height. I don’t have to hunch over to adjust the heat—my back thanks me.”

4. Durability: Controls That Withstand Heavy Commercial Use

Easy operation means nothing if controls break under daily use. The ATT-ABT-BP’s controls are built for commercial rigor:

- Stainless Steel Knobs: Resist scratches, grease buildup, and heat (up to 200°F) – no melted plastic or sticky buttons.

- Sealed Digital Panel: IPX4-rated to repel spills and splashes – safe to wipe clean with a damp cloth mid-shift.

- Reinforced Tilt Lever: Steel core with a rubber grip – tested to 10,000+ uses without loosening.

A 24-hour diner using the ATT-ABT-BP said: “Our bratt pan runs 12 hours a day, and the controls still work like new after 2 years. We clean them 5+ times a day—no damage, no glitches.”

“During our Saturday brunch rush, I’m juggling 3 pans at once. The AT bratt pan’s controls are so easy to use—I can adjust the temperature with one hand while stirring with the other. The tilt lock is a lifesaver when I have to step away for a second. I trained a new cook on it in 15 minutes, and they were using it independently by their second shift.”

5. Spare Parts & Support: Keeping Controls Working Smoothly

Even the easiest-to-use controls need maintenance—and AT Cooker ensures tilting bratt pan spare parts (knobs, tilt levers, control boards) are easy to source, so downtime is minimal:

- Global Parts Network: 50+ warehouses stock common parts (e.g., tilt lever springs, temperature knobs) – 90% ship same-day.

- DIY-Friendly Repairs: Most control parts (like knobs or buttons) can be replaced by in-house staff in 10–15 minutes, using AT’s free repair guides.

- 24/7 Technical Support: Engineers are available to troubleshoot control issues (e.g., unresponsive tilt buttons) via phone or video call.

A catering company said: “Our tilt lever grip wore out—we ordered a replacement from AT’s parts store, and it arrived the next day. One of our staff replaced it during lunch break—no service call needed.”

6. Manufacturer Training & Manuals: Supporting Staff Success

AT Cooker provides free resources to ensure staff get the most out of the bratt pan’s controls:

- Visual User Manual: Step-by-step photos (no complex text) showing how to operate tilting and temperature controls.

- Virtual Training Sessions: 30-minute live demos for new staff, covering control basics and safety tips.

- Quick-Reference Cards: Wallet-sized guides with control icons and functions – posted near the bratt pan for easy access.

A hotel kitchen manager said: “The quick-reference card is perfect for new hires. They keep it in their pocket and refer to it until they memorize the controls—no more constant questions.”

AT Cooker’s Difference: Controls Built for Kitchen Staff

What sets AT Cooker’s induction tilting bratt pan apart is that controls are designed by listening to kitchen staff—not just engineers. Every feature, from the one-handed tilt lever to the labeled presets, solves real pain points:

- Ergonomics reduce fatigue during long shifts.

- Precision eliminates food waste and rework.

- Safety locks and gradual tilting prevent accidents.

- Low training time eases high staff turnover.

Whether your staff are seasoned chefs or new hires, the ATT-ABT-BP’s controls make operating a bratt pan simple, safe, and efficient—even during the busiest shifts.

Get AT Cooker Induction Tilting Bratt Pan Demo

Request a virtual demo to see how easy the tilting and temperature controls are for your kitchen staff. We’ll walk you through operation, training, and maintenance.