Does Heat Cut Off When Chefs Toss the Wok? The Truth About Commercial Induction Continuity

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: The rhythmic “clank-swish” of a tossing wok is the heartbeat of an Asian kitchen. For chefs transitioning to electric, the biggest fear is losing heat mid-air. Does the power cut when you lift? Theoretically, yes. Practically? No. With advanced magnetic field engineering and high-retention 430 stainless steel cauldrons, the AT Cooker DCT-AB 130 ensures that induction wok tossing heat continuity feels just as seamless as gas.

In a traditional Cantonese kitchen, the wok is rarely still. The “Toss” is essential. It mixes ingredients, aerates sauces, and facilitates “Wok Hei” (the breath of the wok). Gas flames are continuous; they heat the air regardless of where the pan is. Induction, however, relies on contact—or at least, proximity.

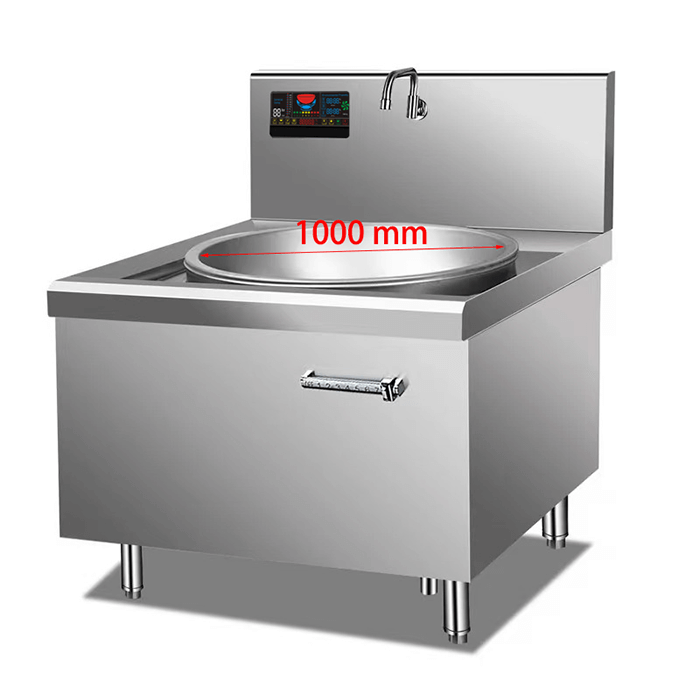

This leads to a common misconception: “If I lift the wok, the cooking stops.” While technically the magnetic connection breaks at a certain distance, modern engineering has solved this practical problem. Using our Freestanding Heavy Duty Induction Wok Cooker DCT-AB 130 as a benchmark, we will analyze the physics of commercial wok pan detection height and why modern induction can keep up with the fastest chefs.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Understanding the “Effective Magnetic Zone”: How High Can You Lift the Pan?

The primary concern regarding induction wok tossing heat continuity is the detection distance. Unlike gas, which has a visible flame, induction uses an invisible magnetic field. The moment the pan leaves this field, energy transfer stops.

However, modern commercial induction coils are designed with a “magnetic envelope” that extends vertically. In the DCT-AB 130, the effective heating zone extends approximately 20-40mm above the ceramic glass. This buffer zone allows chefs to execute the micro-movements of tossing without actually severing the power connection.

2. The Myth of Instant Cooling: Thermal Retention Properties of Heavy-Duty Stainless Steel Woks

There is a flaw in the logic that “heat cuts off.” Heat generation stops, yes, but the heat in the metal does not vanish instantly. The thermal mass of the wok is your battery.

Our DCT-AB 130 uses a 430# stainless iron sheet flanging stamping cauldron. This heavy-duty ferromagnetic material has significant thermal inertia. Even if you lift the wok high into the air for 2 seconds to flip the food, the steel retains its 300°C+ temperature. The food continues to sear mid-air, maintaining the cooking process just as it would over gas.

3. How Smart Sensors Manage the “Micro-Disconnect” During Tossing Motions

Tossing is not a single long lift; it is a series of rapid, rhythmic pulses. You lift, pull back, and drop. The “air time” is often less than 0.5 seconds.

The sensor switch in the AT Cooker controller is programmed with a “hold delay.” When it detects the pan leaving the surface, it doesn’t shut down the system; it enters a “standby-ready” mode. The millisecond the pan re-enters the zone, full power is restored instantly. This rapid cycling is imperceptible to the cooking process.

4. Technique Adjustment: Sliding vs. Lifting for Optimal Induction Connectivity

While you can lift, many chefs find that adjusting their technique yields better results on induction. Instead of the high vertical toss used on a gas “pit” stove, induction favors a “sliding toss.”

By keeping the rear edge of the wok in contact (or near contact) with the curved glass while lifting the front edge to toss, you maintain 100% magnetic connectivity. This technique is more ergonomic, reducing wrist strain, while ensuring zero power loss.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

5. Comparing Heat Recovery Speed: Induction vs. Gas After Pan Re-entry

Let’s say you do lift the pan high enough to cut power. What happens when you land? On a gas stove, the flame is constant, but the pan has cooled slightly in the air.

On the DCT-AB 130, with power options up to 30KW, the recovery is violent (in a good way). The unit dumps massive energy into the steel instantly upon re-entry. This “Turbo Lag” is virtually non-existent, often reheating the pan faster than a gas flame can.

Recovery Time Data

Gas Wok: Linear heating. Recovery relies on flame contact time.

30KW Induction: Exponential heating. Can jump +50°C in seconds upon contact.

6. The Impact of Concave Coil Depth on Magnetic Field Vertical Reach

The shape of the coil matters. Flat coils have very shallow fields. Our concave coils wrap around the sides of the wok. This geometry focuses the magnetic field lines upwards.

This design creates a “bucket” of magnetic energy. Even when the wok is lifted slightly, the sides of the wok often remain within the field generated by the upper edges of the coil, maintaining partial power delivery during the toss.

7. Does the “Clicking” Sound Mean Power Loss During Agitation?

New users often hear a soft clicking or buzzing when tossing. This is not the sound of power failing. It is the sound of the pan detection sensor checking for the wok.

The system pulses rapidly (dozens of times per second) to verify the load. This safety feature ensures that the unit doesn’t waste energy heating the air or a chef’s ring. It is a sign that the commercial wok pan detection height logic is working correctly.

8. Achieving Wok Hei: Is Continuous Fire Essential or Just High Heat?

Wok Hei (breath of the wok) is chemistry: oil polymerization and sugar caramelization at high heat (>300°C). It is not dependent on “fire” but on “temperature.”

Because the AT Cooker induction wok can maintain 300°C on the metal surface even with intermittent contact (thanks to the thermal mass of the heavy cauldron), chefs can achieve authentic Wok Hei without a continuous open flame.

9. The Role of “Holding Time” Settings in Modern Induction Controllers

Advanced commercial units allow for calibration. The pan detection sensor doesn’t have to cut power instantly. In our firmware, there is a micro-tolerance.

This “Holding Time” means the inverter waits a fraction of a second before ramping down power when it detects a lift. If the wok returns within that window (typical of a fast toss), the power curve remains unbroken.

10. Analyzing the Temperature Drop Curve During a 3-Second Toss

Let’s look at the data. If you toss food for 3 seconds:

- Gas: The metal cools by ~15°C due to air exposure, despite the flame below.

- Induction: The metal cools by ~15°C due to air exposure (power off).

The drop is identical. The difference is the recovery. Induction recovers that 15°C in 2 seconds upon landing; gas might take 5 seconds. Therefore, the induction cooker lifting distance “issue” is mitigated by superior recovery speed.

11. Why “Micro-Tossing” Techniques are Preferred by Induction Master Chefs

Chefs adapt. Instead of the exhausting, shoulder-height tossing of the past, induction chefs use “Micro-Tossing.” They use the front lip of the wok as a fulcrum, tilting and shaking the wok vigorously while keeping one point of contact.

This commercial kitchen ergonomic cooking style is faster, requires less energy from the chef, and ensures 100% magnetic continuity for maximum heat transfer.

12. Safety Benefits: Eliminating Grease Flare-Ups When Tossing Over Open Flame

One “feature” of tossing over gas is the flare-up—when oil mist hits the fire. While it looks dramatic, it is a fire hazard and dirties the hood.

Induction eliminates this danger. You get the heat and the toss without the fireball. This results in a cleaner kitchen, lower insurance premiums, and safer staff, all while maintaining the culinary quality of the dish.

| Factor | Gas Wok | AT Cooker Induction (DCT-AB 130) |

|---|---|---|

| Heat Source | Continuous Flame | Magnetic Field (Contact/Proximity) |

| Tossing | Full Lift Possible | 20-40mm Lift or Sliding |

| Recovery | Slow | Instant (30KW) |

| Safety | Flare-up Risk | No Open Flame |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Does heat cut off when you toss? Only for a split second, and it doesn’t matter. The thermal mass of the DCT-AB 130’s 430# stainless cauldron holds the heat, and the 30KW generator restores it instantly.

Modern commercial induction is not about compromising; it’s about evolving. With stock ready in the USA, Germany, France, and beyond, AT Cooker is ready to upgrade your line. Experience the power, precision, and safety of induction stir-frying today. Visit our About Us page to learn more.