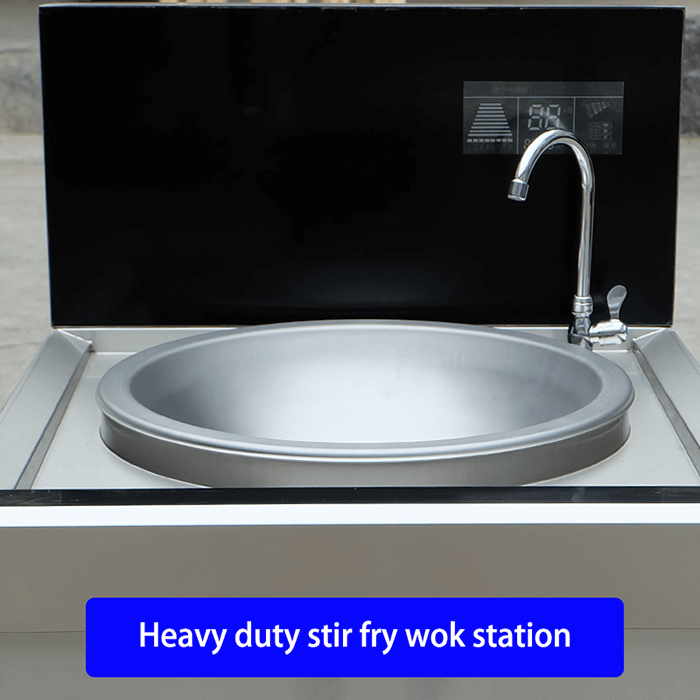

Standardizing “Wok Hei” Flavor: How Restaurant Chains Achieve Consistency with Commercial Induction

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: “Wok Hei”—the breath of the wok—is the holy grail of Asian cuisine. It is that smoky, caramelized flavor that separates a masterpiece from a mediocre stir-fry. For restaurant chains, the challenge isn’t achieving Wok Hei once; it’s achieving it thousands of times a day across 50 different locations. Gas burners rely on the individual skill of the chef, which is variable. Standardizing wok hei flavor requires a digital solution. With AT Cooker Commercial Induction Wok Stations, we turn the art of “Huo Hou” into a programmable science, ensuring every customer tastes the fire, regardless of who is cooking.

For franchise owners and culinary directors, consistency is the currency of brand loyalty. If your Kung Pao Chicken tastes smoky and rich in your flagship store but bland in your suburban outlet, you lose customers. The variable is almost always the heat source. Gas pressure fluctuates, burner nozzles clog, and most importantly, every chef manages a flame differently.

To scale an Asian restaurant concept, you must remove the variables. Commercial induction wok benefits for franchises include precise temperature control, instant recovery, and digital repeatability. By using the AT Cooker Commercial Wok Station, chains can replicate authentic Asian taste with the precision of a computer.

In this strategic guide, we analyze how leading chains use induction to automate excellence and solve the skilled labor shortage.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. The Challenge of Replicating “Breath of the Wok” Across Multiple Locations

Wok Hei is the soul of Cantonese cooking. It is a complex interplay of Maillard reactions, oil vaporization, and extreme heat. In a single restaurant, a master chef can achieve this by feel. In a chain of 100 restaurants, relying on “feel” is a recipe for disaster.

When you have different chefs with different skill levels operating gas burners with varying pressure, the flavor drifts. One location serves smoky, perfect Char Kway Teow; another serves oily, boiled noodles. This inconsistency kills franchise brands. The challenge is not cooking; it is replication.

2. How Digital Power Levels Replace Chef Intuition for Consistent Heat

Gas is analog. “High heat” is a visual estimate. AT Cooker induction is digital. Our units have 8 precise power levels. Level 8 is exactly 30KW of power, every single time, in every single city.

This allows corporate chefs to write recipes based on data, not intuition. “Stir fry at Level 8 for 45 seconds” yields the exact same thermal input in New York as it does in London. This digital backbone is the foundation of chain restaurant kitchen automation.

3. Reducing Dependency on Highly Skilled Wok Chefs for Franchise Expansion

The “Wok Chef” is a dying breed. It takes years to master the temperature control of a gas dragon burner. Finding these masters is hard; retaining them is harder.

Induction simplifies the skill set. Because the heat recovery is instant and the temperature is stable, a junior chef can achieve Wok Hei with weeks of training, not years. This democratizes the skill, allowing franchises to expand without being throttled by a labor shortage.

4. Implementing Standardized SOPs: Locking in Temperature and Time Variables

Standard Operating Procedures (SOPs) are the bible of franchise operations. With gas, SOPs are guidelines. With induction, they are rules.

The Digital SOP

You can program the workflow: Step 1: Heat oil at Level 5 (180°C). Step 2: Sear beef at Level 8 (300°C) for 60 seconds. Step 3: Add sauce, drop to Level 4 to simmer. This repeatability ensures the customer gets the same brand experience every time.

5. The Role of Induction Precision in Eliminating Gas Pressure Variables

Gas pressure fluctuates based on the building, the time of day, and other equipment usage. A “high flame” at 11 AM might be stronger than a “high flame” at 7 PM when the whole block is cooking.

Induction voltage is regulated. The magnetic field output is constant. By eliminating the variable of fuel supply pressure, you remove a major source of cooking inconsistency.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

6. Training New Staff: Shortening the Learning Curve for Wok Hei Mastery

Training on gas involves teaching a chef to “read the fire.” Training on induction involves teaching them to “read the display.” The latter is infinitely faster.

Visual feedback from the LED screen confirms the power output. This immediate feedback loop helps new cooks build muscle memory faster, reducing training costs and waste during the onboarding process.

7. Menu Engineering: Adapting Traditional Recipes for Digital Wok Stations

Adapting a menu for digital control stir fry equipment is a strategic process. Culinary directors work with AT Cooker to map traditional thermal curves to induction power settings.

Once mapped, these settings become the standard. You can deploy a “Spicy Szechuan Beef” recipe that specifies “Level 7” instead of “High Heat,” ensuring the chilies toast without burning across 50 locations.

8. Hardware Consistency: Why Pan Material and Shape Must Be Uniform Across Branches

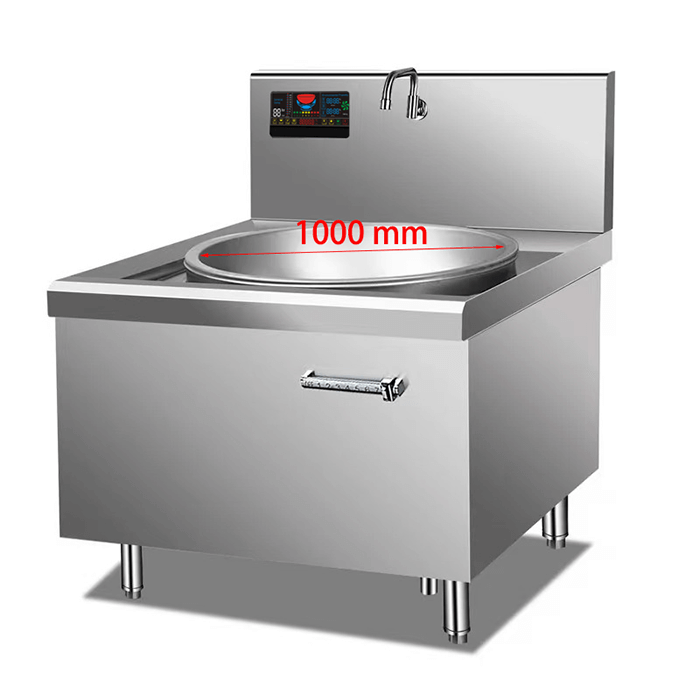

Induction relies on the interaction between the coil and the pan. To achieve standardization, the hardware must be identical. AT Cooker supplies matched woks (409/430 stainless steel) with specific curvatures.

Using the exact same pan on the exact same coil ensures that the magnetic coupling efficiency is identical in every store, removing hardware variables from the flavor equation.

9. Ensuring Flavor Profile Identity in Quick Service Restaurant (QSR) Chains

In QSR, speed and sameness are virtues. If your “Smoky Fried Rice” is smoky in Branch A but oily in Branch B, your brand suffers.

Induction’s ability to recover temperature instantly (Zero Lag) ensures that every batch gets the thermal shock needed to vaporize oil and create flavor, regardless of how busy the store is.

10. Digitizing “Huo Hou”: Converting Master Chef Heat Curves into Programmable Data

“Huo Hou” (Heat Control) is the art of manipulating fire over time. We digitize this art. By analyzing the thermal profile of a master chef’s dish, we can break it down into data points.

This data becomes the programming logic for the induction controller. It is essentially “cloning” the master chef’s technique into the microchip of every unit in your chain.

11. Solving the “Satellite Kitchen” Dilemma: Preserving Wok Hei During Distribution

Central kitchens often cook sauces or proteins to be finished at satellite locations. Maintaining quality during this “finish” is hard.

Induction allows satellite kitchens (which often lack heavy gas infrastructure) to execute high-heat finishing moves that restore Wok Hei to pre-cooked items, ensuring the final product tastes fresh, not reheated.

12. Cost Analysis: Reducing Food Waste from Inconsistent Cooking Quality

Inconsistent heat leads to burnt food or soggy returns. This waste cuts into margins. By stabilizing the heat source with induction, you reduce the error rate.

Less burnt food means lower food costs. Consistent quality means fewer customer refunds. The ROI of induction comes not just from energy savings, but from yield optimization.

| Metric | Gas Kitchen | AT Cooker Induction |

|---|---|---|

| Heat Consistency | Variable (Pressure dependent) | Exact (Digital) |

| Chef Skill Needed | High (Master) | Medium (Trained) |

| SOP Adherence | Difficult | Enforced |

| Scalability | Hard | Easy |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

Standardizing Wok Hei is no longer a paradox. With AT Cooker Commercial Induction Woks, it is a replicable business process. We empower chains to serve authentic flavor at scale.

With stock ready for rapid deployment in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we are the partner you need for franchise expansion. Visit our About Us page to start standardizing your success.