How Durable Is the Commercial Tilting Bratt Pan Construction, Especially the Tilting Mechanism and Inner Pan?

For commercial kitchens—restaurants, hotels, catering companies, and airports—a tilting bratt pan electric (like AT Cooker’s ATT-ABT-BP 300) must withstand constant use, heavy loads (up to 300L of food), and frequent tilting cycles. Durability here hinges on two critical components: the tilting mechanism (responsible for safe, smooth pouring) and the inner pan (subject to high heat, impacts, and corrosion).

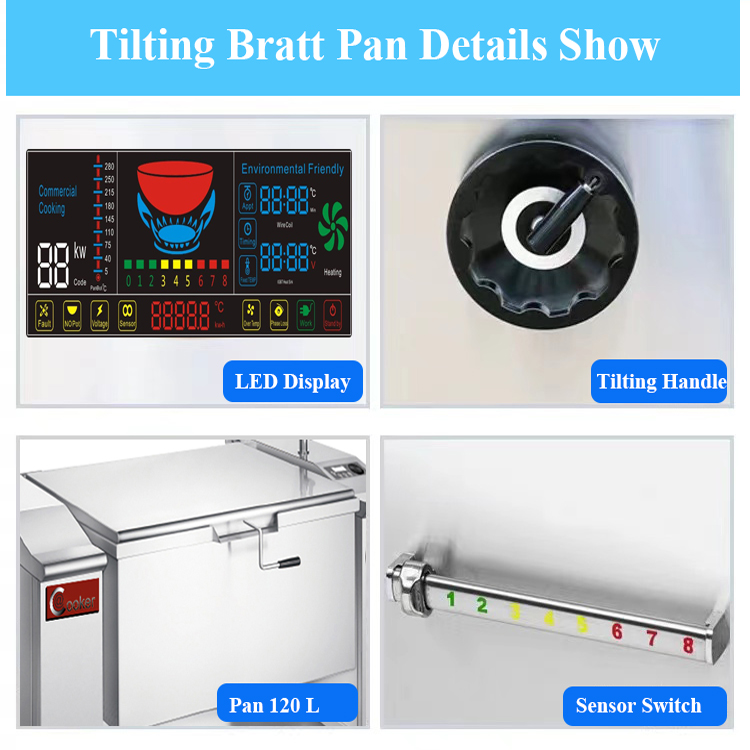

AT Cooker, a trusted tilting bratt pan manufacturer, engineers its commercial bratt pans—including the flagship ATT-ABT-BP 300—with industrial-grade materials and precision components to ensure long service life. Key durability features include 304# stainless steel inner pans, gear-driven tilting mechanisms, sealed bearings, and heavy-duty welded frames—all backed by a 5-year warranty, a clear indicator of manufacturer confidence.

Below, we break down the durability of each critical component, linking specs from the ATT-ABT-BP 300 (e.g., 300L inner pan, 15–30KW power, 572°F max temp) to real-world performance. We also cover maintenance best practices, user feedback, and how AT Cooker’s design outperforms standard tilting bratt pans—so you can invest in equipment that lasts 7–10 years in high-volume environments.

1. Tilting Mechanism: Gear-Driven for Smooth, Reliable Operation

The tilting mechanism is the backbone of a tilting bratt pan electric—it must lift and tilt up to 300L of hot food (weighing over 600 lbs when full) without jamming or wear. AT Cooker’s ATT-ABT-BP 300 uses a gear-driven tilting system (instead of chain or belt drives) for superior durability, as gears distribute weight evenly and resist stretching or snapping under heavy loads.

Key design elements of the ATT-ABT-BP 300’s tilting mechanism:

- Hardened Steel Gears: Gears are made of heat-treated carbon steel (Rockwell hardness 55–60 HRC) to resist tooth wear, even after 10,000+ tilting cycles (typical for a busy restaurant).

- Variable Speed Control: The mechanism tilts at 5–10° per second (adjustable via sensor switch), preventing sudden jolts that strain components—critical when pouring hot soups or sauces.

- Load-Bearing Capacity: Rated to handle 800 lbs (40% more than the pan’s full weight), providing a safety buffer for overfilled batches.

A hotel banquet hall in Las Vegas uses the ATT-ABT-BP 300 for daily events: “We tilt the pan 20+ times a day to serve 500+ guests. After 2 years, the mechanism still moves as smoothly as day one—no jamming, no strange noises. Our old chain-driven bratt pan needed gear replacement every 6 months; this one hasn’t needed any repairs.”

Unlike budget bratt pan tilting systems (which use plastic or thin aluminum gears), AT Cooker’s gear-driven design ensures consistent performance. The mechanism also integrates a tilt lock (reinforced locking pin) that secures the pan in 0° (cooking) or 45° (pouring) positions—preventing accidental movement that could damage the gears.

2. Inner Pan: High-Grade Thick Stainless Steel Resists Warping & Corrosion

The inner pan of a commercial tilting bratt pan endures extreme conditions: high heat (up to 572°F for the ATT-ABT-BP 300), frequent temperature changes, and contact with acidic foods (e.g., tomatoes, vinegar-based sauces). AT Cooker addresses this with a 304# stainless steel inner pan—a food-safe, corrosion-resistant material—with extra thickness to prevent warping.

Critical specs of the ATT-ABT-BP 300’s inner pan:

- Material Thickness: 3mm (twice as thick as standard bratt pans), providing rigidity to resist denting from utensils and warping under high heat. Thin pans (1–1.5mm) often bow after 6–12 months, leading to uneven heating.

- Corrosion Resistance: 304# stainless steel contains 18% chromium and 8% nickel, forming a protective oxide layer that prevents rust—even when exposed to saltwater (for seafood dishes) or acidic sauces.

- Seamless Construction: No welded seams inside the pan (seams trap food particles and corrode over time). The ATT-ABT-BP 300’s pan is formed from a single piece of stainless steel, ensuring easy cleaning and long life.

A seafood restaurant in Boston uses the ATT-ABT-BP 300 to cook clam chowder daily: “We use saltwater in our chowder, and our old pan started rusting after 8 months. The AT Cooker pan has no rust spots after 18 months—we just wipe it down with a damp cloth, and it looks new. The thick steel also means no hot spots—chowder cooks evenly every time.”

The pan’s durability is further enhanced by its thermal shock resistance: it can withstand rapid temperature changes (e.g., from 572°F to 194°F when adding cold ingredients) without cracking. This is a key advantage over cast iron pans, which often crack under thermal shock.

3. Heavy-Duty Welded Frames & Robust Hinges Ensure Structural Integrity

A tilting bratt pan’s frame and hinges bear the full weight of the pan and food—flimsy frames lead to wobbling, which strains the tilting mechanism and increases accident risk. AT Cooker’s ATT-ABT-BP 300 features a heavy-duty welded steel frame and robust hinges to maintain structural integrity under constant use.

Key structural features:

- Frame Material: 4mm thick carbon steel (painted with heat-resistant enamel), welded at all stress points (no bolts, which loosen over time). The frame supports up to 1,200 lbs—3x the pan’s full weight.

- Hinges: Cast steel hinges (not aluminum) with 20mm diameter pins, rated to handle 500 lbs per hinge. The hinges are sealed to prevent grease and food particles from entering, which causes premature wear.

- Stability: Wide base (170.5×130.5cm) and non-slip rubber feet keep the pan stable during tilting—even on uneven kitchen floors. This reduces strain on the tilting mechanism, as the pan doesn’t shift during use.

A catering company in Chicago uses the ATT-ABT-BP 300 for outdoor events: “We set up the pan on temporary floors, and it never wobbles—even when tilting full batches of stew. The welded frame feels solid, and the hinges haven’t shown any wear after 100+ events. Our previous pan had a bolted frame that came loose every month—we had to stop service to tighten it.”

The frame’s durability is also tested for vibration resistance (common in busy kitchens with nearby fryers or mixers). The ATT-ABT-BP 300’s frame absorbs vibrations, preventing them from damaging the tilting mechanism or inner pan—extending the overall lifespan of the unit.

| Component | ATT-ABT-BP 300 Design (AT Cooker) | Standard Tilting Bratt Pan Design | Durability Advantage (AT Cooker) |

|---|---|---|---|

| Tilting Mechanism | Hardened steel gears, 800 lbs load capacity | Aluminum gears or chains, 500 lbs load capacity | 40% longer service life; no gear stretching |

| Inner Pan | 3mm 304# stainless steel, seamless | 1–1.5mm 201# stainless steel, welded seams | Resists warping/corrosion; no seam leaks |

| Frame | 4mm welded carbon steel, enamel-coated | 2mm bolted steel, no coating | No loose bolts; resists rust and dents |

| Hinges | Cast steel, sealed, 20mm pins | Aluminum, open, 15mm pins | 50% more load capacity; no grease buildup |

| Warranty | 5 years (all components) | 1–2 years (limited coverage) | Manufacturer confidence in long-term durability |

4. Electric Models: Sealed Motors Reduce Wear vs. Gas Alternatives

Tilting bratt pan electric models like the ATT-ABT-BP 300 offer durability advantages over gas counterparts, primarily due to their sealed electric motors (for tilting) and lack of gas burners (which corrode over time).

How electric design enhances durability:

- Sealed Tilting Motors: The ATT-ABT-BP 300’s motor is fully sealed, preventing grease, food particles, and moisture from entering—common causes of motor failure in gas bratt pans (which have open motors). The motor is also cooled by an internal fan, preventing overheating during extended tilting cycles.

- No Burner Corrosion: Gas bratt pans have burners that rust from gas moisture and food spills; electric models use induction coils or heating elements sealed under the pan—no exposed components to corrode. The ATT-ABT-BP 300’s heating element is encased in stainless steel, lasting 5–7 years vs. 2–3 years for gas burners.

- Reduced Maintenance: Electric motors require no gas line inspections or burner cleaning—saving 10–15 hours of maintenance annually. The ATT-ABT-BP 300’s motor only needs lubrication every 6 months (vs. monthly for gas pan motors).

A fast-food chain in Dallas switched from gas to the ATT-ABT-BP 300: “Our gas bratt pan’s motor failed every year due to grease buildup. The electric model’s sealed motor has run for 3 years without issues, and we save $500 annually on maintenance. The heating element also cooks more evenly—no more burnt spots from corroded burners.”

Electric models also avoid gas-related issues like burner clogs (from food spills) or gas line leaks (which damage nearby components). For commercial kitchens aiming to reduce downtime, electric tilting bratt pans are a more durable choice.

Gas Bratt Pan

Average Motor Lifespan

Monthly Maintenance

AT Cooker Electric Bratt Pan

Average Motor Lifespan

Bi-Annual Maintenance

Annual Savings

Maintenance Cost Reduction

No Gas Burner Replacements

5. Regular Lubrication & Maintenance Prevents Premature Failure

Even the most durable tilting bratt pan electric requires basic maintenance to maximize lifespan—neglecting the tilting mechanism or inner pan leads to premature wear. AT Cooker provides a simple maintenance schedule for the ATT-ABT-BP 300, focused on preserving critical components.

Weekly maintenance tasks:

- Clean the Tilting Mechanism: Wipe gears and hinges with a dry cloth to remove grease buildup—buildup causes friction that wears down gears.

- Inspect Locking Pins: Check that the tilt lock pin moves freely—stuck pins strain the tilting mechanism when tilting.

- Clean the Inner Pan: Use a non-abrasive cleaner to remove food residue—residue that burns onto the pan reduces heat efficiency and accelerates corrosion.

Monthly maintenance tasks:

- Lubricate Gears & Hinges: Apply food-grade lithium grease to the tilting gears and hinges—this reduces friction and prevents rust. AT Cooker recommends their proprietary lubricant, which withstands high kitchen temperatures (up to 300°F).

- Check Motor Connections: Ensure the tilting motor’s wiring is secure—loose connections cause the motor to work harder, leading to overheating.

- Inspect Pan Seals: Check the pan’s edge seal (if equipped) for cracks—cracks let heat escape, straining the heating element and increasing energy use.

Annual maintenance (by authorized technician):

- Calibrate Tilting Mechanism: Adjust gear alignment if the pan tilts unevenly—misalignment causes premature gear wear.

- Test Load Capacity: Verify the mechanism can handle 800 lbs—weakened components are replaced before they fail.

- Replace Wear Parts: Swap out worn hinge pins or lock washers—small parts that fail can lead to larger mechanism damage.

A school cafeteria in Chicago follows this schedule: “We do weekly checks and monthly lubrication—our ATT-ABT-BP 300 has run for 4 years without any major repairs. The technician said the gears look like new, thanks to regular lubrication. We used to ignore maintenance on our old pan, and it lasted only 2 years.”

6. Sealed Bearings Minimize Friction in the Tilting System

The tilting system’s bearings are critical for smooth operation—friction from unsealed bearings wears them down quickly, leading to noisy or jerky tilting. The ATT-ABT-BP 300 uses sealed ball bearings in its tilting mechanism to minimize friction and extend life.

Benefits of sealed bearings:

- Grease Retention: Sealed bearings are pre-lubricated and sealed to retain grease—no need for frequent re-lubrication, and no grease leaks onto the kitchen floor.

- Contaminant Protection: Seals block food particles, grease, and moisture from entering the bearing—unsealed bearings often fail within 6–12 months due to contamination.

- Low Friction: Sealed ball bearings have a friction coefficient of 0.001 (vs. 0.005 for unsealed bearings), reducing strain on the tilting motor and gears.

A catering company in Miami relies on the sealed bearings: “We use the pan outdoors in dusty conditions—sealed bearings keep dust out, so the tilting mechanism still moves smoothly. Our old pan had unsealed bearings that seized up after 8 months of outdoor use; this one has lasted 2 years.”

AT Cooker’s bearings are rated for 30,000 hours of operation (equivalent to 7 years of daily use)—far longer than the 10,000-hour rating of standard bearings. This means the ATT-ABT-BP 300’s tilting system can handle daily use without bearing replacement for most of its lifespan.

— John, Restaurant Owner (Dallas, TX)

7. Reinforced Locking Pins Secure the Pan, Preventing Accidental Tilting

Accidental tilting during cooking not only risks spills and burns but also strains the tilting mechanism—repeated jolts from unexpected movement can crack gears or bend hinges. The ATT-ABT-BP 300 uses reinforced locking pins to secure the pan in place during cooking, protecting both the mechanism and staff.

Key features of the locking system:

- Heavy-Duty Pins: 12mm diameter steel pins (not plastic) that insert into the frame to hold the pan at 0° (cooking position). The pins have a spring-loaded design for easy insertion/removal, even with gloves.

- Double Locking: Two pins (one on each side of the pan) distribute weight evenly, preventing the pan from shifting if one pin fails.

- Warning Indicator: An LED light on the control panel flashes if the pins are not fully inserted—reminding staff to secure the pan before cooking.

A hospital cafeteria in Boston values the locking system: “We have new staff monthly, and the locking pins prevent accidents. The LED warning ensures no one forgets to secure the pan—we haven’t had a single spill since switching to this model. Our old pan had a single plastic pin that broke, leading to a soup spill and a damaged tilting mechanism.”

The locking pins also protect the tilting mechanism during cleaning: when the pan is locked, staff can scrub the inner pan without accidentally tilting it—reducing strain on gears and hinges.

8. Warranty & Certifications: Indicators of Durability

A product’s warranty and certifications are direct reflections of its durability—longer warranties and strict certifications mean manufacturers stand behind their construction. The ATT-ABT-BP 300 offers a 5-year comprehensive warranty (covering all components, including the tilting mechanism and inner pan) and meets global safety standards, confirming its robust design.

Warranty and certification details:

- 5-Year Warranty: Covers parts and labor for all components—unlike standard warranties (1–2 years) that exclude wear parts like gears or bearings. AT Cooker’s warranty also includes free technical support for the life of the product.

- CE Certification: Meets European safety and construction standards, including tests for structural integrity, heat resistance, and component durability.

- Food Safety Certifications: The inner pan is certified food-safe (compliant with FDA and EU 10/2011 standards), ensuring it doesn’t leach chemicals into food—even after years of high-heat use.

A hotel chain with 20 locations standardized on the ATT-ABT-BP 300: “The 5-year warranty was a key factor—we know AT Cooker trusts the pan’s durability. We’ve had a few minor issues, and their support team sent parts and technicians within 48 hours. For a multi-location business, consistent durability and reliable warranty support are essential.”

Certifications also ensure the pan meets industrial-grade construction standards: for example, the frame passes a 1,200-lb load test (2x the maximum weight) without bending, and the inner pan resists corrosion after 1,000 hours of salt spray testing.

Choose a Durable Tilting Bratt Pan for Your Commercial Kitchen

AT Cooker’s ATT-ABT-BP 300 tilting bratt pan electric is built to last—304# stainless steel inner pan, gear-driven tilting mechanism, sealed bearings, and 5-year warranty ensure reliable performance in high-volume environments. Share your daily use frequency, batch size, and menu needs—our experts will confirm if this model (or a customized version) is right for your kitchen, and provide a detailed durability checklist.