Is the Transition Hard? Helping Traditional Chefs Adapt to Commercial Induction Woks

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Change is hard, especially in a professional kitchen. For a veteran chef who has spent 30 years controlling heat by the roar of a gas burner, the silence of induction can be unsettling. “Will it be fast enough? Does it feel right?” These are common fears. However, transitioning from gas to induction wok cooking is not about erasing skill; it’s about upgrading the tool. At AT Cooker, we find that once chefs experience the speed, comfort, and precision of our equipment, they never want to go back. Here is the roadmap for a smooth transition.

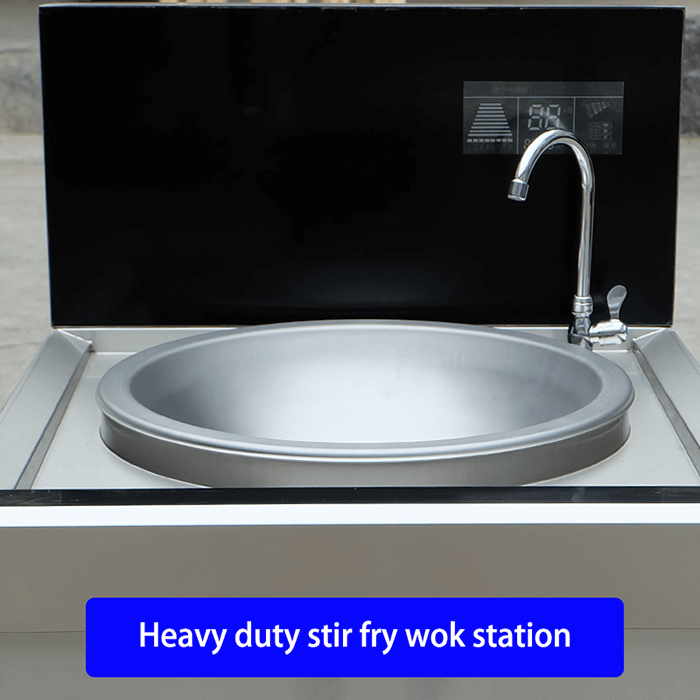

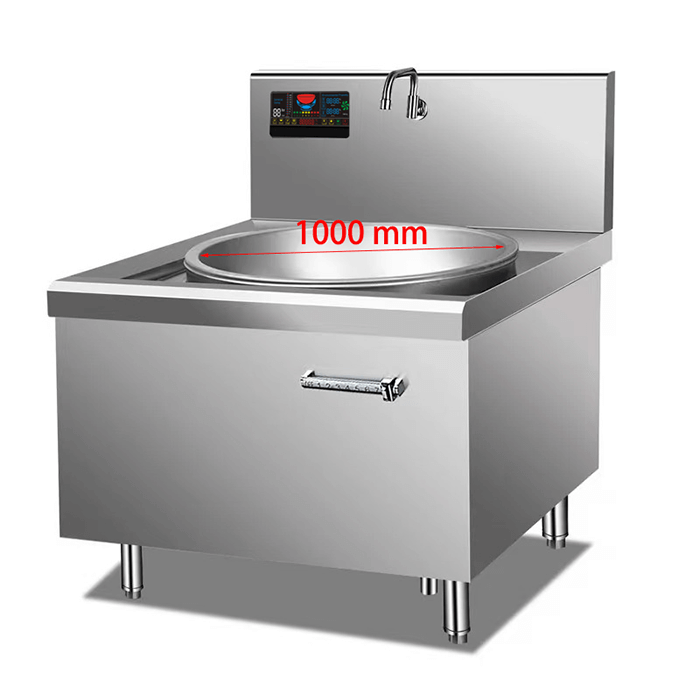

The resistance to new technology in commercial kitchens is legendary. Chefs are creatures of habit, relying on muscle memory and sensory cues—the sight of the blue flame, the sound of the jet burner, the heat on their forearms. Replacing a gas dragon with a high-tech glass-ceramic bowl feels like a fundamental shift in reality.

But the shift is inevitable. Rising gas prices, ventilation costs, and the need for cooler kitchens are driving owners toward electric. The good news? The induction cooking learning curve is much shorter than most expect. With the right training and mindset, a team can adapt to an AT Cooker Commercial Wok Station in less than a week.

In this guide, we address the psychological and physical adjustments required to modernize your workflow.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Overcoming the “No Flame” Psychological Barrier: Relying on Sizzle Instead of Sight

Chefs cook with their eyes. The biggest hurdle to transitioning from gas to induction wok cooking is the absence of visual feedback. There is no blue flame to judge intensity.

We train chefs to shift their senses. Instead of looking at the fire, listen to the sizzle. The sound of oil hitting the smoking hot steel of an AT Cooker wok is identical to gas. Once a chef realizes the heat is there—instantly and powerfully—the need for a visual crutch disappears.

2. Adjusting Tossing Techniques: Staying Within the Magnetic Field Vertical Range

On a gas pit, you can lift the wok 6 inches, and the flame follows. On induction, the magnetic field drops off after 2-4 cm. This requires a technique adjustment.

Chefs must learn the “Slide and Tilt” method. Instead of lifting the entire wok, keep the back edge close to the curved glass while tossing. This maintains the magnetic connection and keeps the power at 100%. Our concave coil design is forgiving, but muscle memory needs a slight recalibration.

3. Retraining Muscle Memory: Digital Dial Controls vs. Traditional Knee Valves

Old-school chefs use knee valves to control gas flow hands-free. Commercial induction uses knobs, sliders, or magnetic sensors.

This is the hardest muscle memory to break. However, digital controls offer exact repeatability. “Level 8” is always the same heat. We encourage chefs to see this as a precision tool. After a few shifts, the hand movement becomes as automatic as the knee movement was.

4. The Speed Factor: Learning to Prep Ingredients Faster to Match Instant Heat

Induction is too fast for some chefs at first. On gas, you turn on the burner and then chop the garlic while the pan heats. On induction, if you turn it on and walk away, the oil smokes in seconds.

Modernizing commercial kitchen workflow means prepping everything before heating the pan. Mise en place must be tighter. This discipline actually improves overall kitchen speed and organization.

5. Improving Kitchen Communication: How Lower Noise Levels Aid Team Coordination

A gas kitchen is a roar of combustion fans. Chefs have to shout to be heard. Induction is silent.

The first thing chefs notice is the quiet. This lowers stress levels and allows for normal conversation. Expeditors don’t have to scream. This improving kitchen ergonomics factor is often the most appreciated benefit after the first week.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

6. The Ergonomic Buy-In: Why Chefs Appreciate the Cooler Working Environment

The “Buy-In” happens when the chef realizes they aren’t sweating. A gas wok station is 50°C. An induction station is 25°C.

Once a veteran chef finishes a Friday night service without being dehydrated and exhausted from heat stress, they become the biggest advocates for induction. The comfort factor wins them over.

7. Standardizing “Huo Hou”: How Digital Precision Helps Junior Chefs Catch Up

“Huo Hou” (control of fire) usually takes years to learn. With digital power levels, it becomes data.

Head chefs can tell juniors: “Sear at Level 9 for 30 seconds.” This shortens the commercial kitchen staff training time significantly, allowing new recruits to produce high-quality stir-frys in weeks, not years.

8. Cleaning Incentives: The Shift from Scrubbing Carbonized Burners to Wiping Glass

Nobody likes cleaning gas burners. They are greasy, carbonized, and heavy. Cleaning an induction wok involves spraying water and wiping a smooth glass surface.

This 90% reduction in cleaning labor is a massive morale booster for the closing shift. It is a tangible benefit that staff feel every night.

9. Handling Pan Weight: The Difference Between Composite Induction Woks and Traditional Iron

Induction woks (made of ferritic stainless or clad layers) can be slightly heavier than thin carbon steel hand-hammered woks.

Chefs may need a few days to adjust to the balance. However, since the tossing technique is more “sliding” than “lifting,” the perceived weight during cooking is often less strain on the wrist.

10. Addressing the “Wok Hei” Myth: Proving Flavor is About Temperature, Not Fuel Source

The hardest heart to win is the one that believes in the magic of fire. We prove it with a blind taste test.

When chefs see that the oil vaporizes and the scallions char exactly the same way at 300°C on induction as they do on gas, the myth dissolves. Heat is physics, not magic.

11. Feedback Loops: How Visual Power Displays Replace the Intuition of Flame Height

On gas, you look at the flame size. On induction, you look at the LED bar graph.

This visual feedback is actually more accurate. A flame can look big but be weak due to low gas pressure. A digital display reading “30KW” guarantees you are getting 30KW. Chefs quickly learn to trust the screen.

12. Typical Adaptation Timeline: How Long Before a Veteran Chef Feels Comfortable?

- Day 1-2: Frustration. “It’s too fast! I burned the garlic.”

- Day 3-5: Calibration. “Okay, Level 4 is for simmering, Level 8 is for searing.”

- Week 2: Preference. “Please don’t make me go back to the hot gas kitchen.”

The transition is a U-curve, but the destination is a happier, faster kitchen team.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

The transition to induction is not a hurdle; it is an evolution. By supporting your chefs with training and high-quality equipment like the AT Cooker Commercial Wok Station, you are investing in their future and yours.

With global stock in the USA, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria, we can help you modernize today. Visit our About Us page to start the journey.