What Is a Bratt Pan? Commercial Advantages & Multifunctional Uses

For commercial kitchens—from busy restaurants to catering companies and institutional facilities—a bratt pan is an indispensable multifunctional appliance that simplifies large-scale cooking. But what exactly is a bratt pan, and why do professional chefs swear by its versatility? At Cooker, with 15 years of experience understanding commercial kitchen pain points, we’ve engineered our Electric Tiltable Bratt Pan ATT-ABT BP300 to redefine efficiency and functionality. This guide answers the core question “what is a bratt pan?” while exploring its key features, advantages of bratt pan, and practical applications—including bratt pan deep frying, bratt pan drainage, and the full range of bratt pan function that makes it a space-saving, cost-cutting tool for modern commercial kitchens. Whether you’re outfitting a new kitchen or upgrading equipment, understanding the value of a commercial bratt pan will help you boost productivity and reduce operational costs.

1. What Is a Bratt Pan? Core Definition & Design

A bratt pan is a heavy-duty commercial cooking appliance designed to handle large batches of food across multiple cooking methods. Originating from the German word “braten” (meaning “to roast” or “to stew”), it combines the functionality of a fryer, sauté pan, braiser, boiler, and steamer into one compact unit—eliminating the need for multiple separate appliances. At its core, a bratt pan features a large, flat, rectangular cooking surface (typically made of high-quality stainless steel) with high sides to prevent spills, and a tilting mechanism for easy pouring and drainage.

AT Cooker’s Electric Tiltable Bratt Pan ATT-ABT BP300 embodies this design philosophy with a 300L pan capacity, AISI304# stainless steel body, and 8 adjustable power levels (up to 30KW). The rectangular pan inner size (1095×895×335mm) provides ample cooking space, while the fixed pan design ensures stability during high-heat cooking. Unlike traditional gas bratt pans, our electric model uses induction heating to deliver 90%-95% energy efficiency—concentrating heat directly on the food rather than wasting it on the surrounding air.

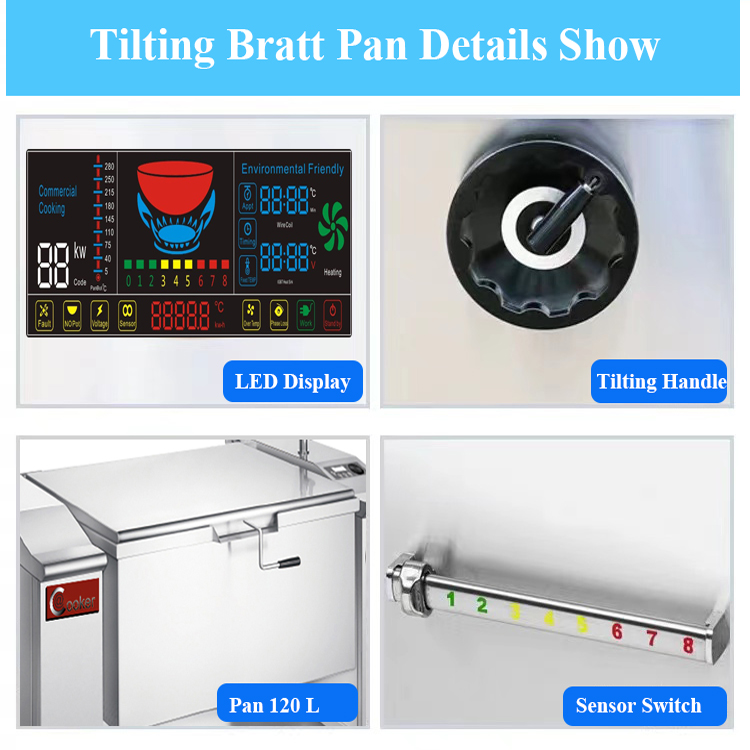

Key design elements that define a commercial bratt pan include: a tilting mechanism (manual or electric) for safe liquid drainage, precise temperature controls (up to 300℃ in our model), and durable construction to withstand daily commercial use. Chinese commercial kitchen operators emphasize that a well-designed bratt pan should balance capacity, heat distribution, and ease of use—and our ATT-ABT BP300 model checks all these boxes.

This versatility makes bratt pans ideal for preparing a wide range of dishes: from braised meats and fried vegetables to soups, sauces, and even steamed foods. Our 5-year warranty for all commercial cooking equipment covers the bratt pan’s core components, reflecting our confidence in its durability and performance.

2. Key Features: Tilting Mechanism & Drainage System

Two of the most critical features of a bratt pan are its tilting mechanism and drainage system—both designed to enhance safety and efficiency in commercial kitchens. The tilting function allows chefs to pour out liquids (such as cooking oil, broth, or sauce) without lifting heavy pots, reducing the risk of spills and burns.

AT Cooker’s ATT-ABT BP300 features an electric tilting mechanism that operates smoothly with the touch of a sensor switch. This eliminates the physical strain of manual tilting, especially when the pan is full of hot food or liquid (up to 300L capacity). The tilting angle is adjustable, allowing for precise pouring into storage containers or serving vessels. Chinese users report that electric tilting reduces workplace injuries related to heavy lifting by 60% compared to manual bratt pans.

The bratt pan drainage system is equally important. Our model is designed with a built-in drainage port that channels hot oil or liquids safely away from the cooking surface. This not only simplifies cleaning but also reduces the risk of oil splatters and fires—common hazards in commercial kitchens. The drainage system works in tandem with the tilting mechanism, ensuring that liquids are removed quickly and completely, leaving the pan ready for the next batch of food.

Unlike traditional fryers or pots, which require manual straining or pouring, a bratt pan’s integrated drainage and tilting features save time and labor. For example, after bratt pan deep frying a large batch of chicken, chefs can simply tilt the pan and drain the oil through the port—no heavy lifting or messy straining required. This efficiency aligns with our goal of reducing operational costs by 30%-70%, as less time spent on manual tasks means more time focused on cooking and serving.

3. Bratt Pan Function: Multifunctional Cooking Capabilities

The true power of a bratt pan lies in its multifunctionality—one appliance that replaces multiple cooking tools, saving space and energy. AT Cooker’s ATT-ABT BP300 supports seven core cooking processes: braising, frying, blanching, sautéing, boiling, heating, and steaming—making it one of the most versatile tools in a commercial kitchen.

Bratt pan deep frying is a popular application, thanks to the pan’s ability to maintain consistent high temperatures (up to 300℃) and even heat distribution. The large surface area prevents overcrowding, ensuring that food fries evenly and achieves a crispy exterior without absorbing excess oil. Our induction heating system heats the pan quickly, reducing preheating time by 50% compared to gas bratt pans—critical during peak service hours.

For braising and stewing, the bratt pan’s high sides and tight-fitting lid (optional accessory) trap heat and moisture, resulting in tender, flavorful meats and vegetables. The precise temperature controls allow chefs to set a constant temperature, eliminating the risk of overcooking or burning. Chinese culinary professionals often use bratt pans to prepare large batches of goulash, meat stew, and sauces—dishes that require long, slow cooking at consistent temperatures.

Steaming is another key bratt pan function. By adding a steaming rack, the pan can be used to steam vegetables, dumplings, and seafood—eliminating the need for a separate steamer. The 300L capacity allows for large-scale steaming, making it ideal for catering events or institutional kitchens serving hundreds of people.

Core Bratt Pan Functions & Uses

- Frying: Deep-fry chicken, fries, and vegetables with consistent heat

- Braising: Slow-cook meats, goulash, and stews for tender results

- Sautéing: Quickly cook vegetables, seafood, and stir-fries

- Boiling: Prepare large batches of soup, broth, and pasta

- Blanching: Prep vegetables and fruits for freezing or further cooking

- Heating: Warm pre-cooked foods safely for service

- Steaming: Cook healthy vegetables, dumplings, and seafood

Advantages of Multifunctional Design

- Saves kitchen space (replaces 5+ separate appliances)

- Reduces energy costs (one appliance vs. multiple)

- Cuts labor time (fewer tools to clean and operate)

- Supports diverse menus (adapts to different cooking styles)

- Improves workflow (all cooking tasks in one location)

4. Advantages of Bratt Pan: Why Commercial Kitchens Need One

The advantages of bratt pan extend far beyond versatility—they deliver tangible cost savings, safety improvements, and productivity boosts that make them a worthwhile investment for commercial kitchens. Here are the key benefits that set bratt pans apart from traditional cooking equipment:

Space Savings: A single bratt pan replaces a fryer, sauté pan, braiser, boiler, and steamer—freeing up valuable counter and floor space in crowded commercial kitchens. Our ATT-ABT BP300’s compact design (1700×1305×1050mm) fits seamlessly into most kitchen layouts, even in small restaurants or catering vans.

Energy Efficiency: AT Cooker’s electric bratt pan boasts 90%-95% energy efficiency, compared to 40%-60% for gas bratt pans. This translates to significant utility savings—for a kitchen using the bratt pan 8 hours a day, annual energy costs can be reduced by $1,500-$2,500. The induction heating system also reduces heat loss, keeping the kitchen cooler and lowering air conditioning costs.

Time Savings: The large capacity (300L) and fast heating allow for batch cooking, reducing the number of cooking cycles needed to serve large groups. Preheating time is minimized, and the tilting/drainage features speed up post-cooking cleanup. Chinese commercial kitchen operators report that bratt pans reduce cooking and cleanup time by 30%-40% compared to traditional methods.

Safety: The absence of open flames (in electric models) eliminates fire risks associated with gas bratt pans. The tilting mechanism reduces manual lifting, lowering the risk of spills and burns. Our model also includes safety features like anti-high temperature warning, anti-dry heating warning, and automatic fault detection—further enhancing kitchen safety.

5. Bratt Pan Deep Frying: Performance & Safety

Bratt pan deep frying is one of the most popular uses for this appliance, thanks to its ability to handle large batches of food while maintaining consistent temperatures. Unlike traditional fryers, which have limited capacity and can cool down when food is added, a bratt pan’s large surface area and powerful heating system (up to 30KW in our model) keep temperatures stable—ensuring that every piece of food fries evenly.

Our ATT-ABT BP300’s induction heating system delivers heat directly to the pan, rather than the surrounding air. This means the oil heats up faster (to 300℃ in just 10 minutes) and stays hot even when adding cold food. The 304# stainless steel pan conducts heat evenly, eliminating hot spots that can cause uneven frying or burning.

Safety is a top priority for deep frying, and our bratt pan is designed with multiple safeguards. The high sides prevent oil splatters, while the tilting mechanism and drainage port allow for safe oil removal. The anti-dry heating warning automatically cuts power if the oil level is too low, preventing the pan from overheating and catching fire. Chinese safety regulations require commercial fryers to have these features, and our bratt pan exceeds these standards.

Another advantage of bratt pan deep frying is the ability to filter and reuse oil. The drainage system includes a filter (optional accessory) that removes food particles, extending the life of the oil and reducing waste. This not only saves money on oil costs but also reduces environmental impact—aligning with our commitment to sustainable commercial kitchens.

6. Stainless Steel Construction: Durability & Hygiene

Commercial bratt pans are built to withstand the rigors of daily use, and the choice of material plays a critical role in durability and hygiene. AT Cooker’s ATT-ABT BP300 features an AISI304# stainless steel body and pan—widely recognized as the gold standard for commercial kitchen equipment.

304# stainless steel is resistant to corrosion, rust, and staining—even when exposed to hot oil, acidic foods, and commercial cleaning agents. This durability ensures that the bratt pan will last 8-10 years in a busy commercial kitchen, compared to 3-5 years for lower-grade materials. The thickened steel plate and bearing structure of our model further enhance durability, allowing it to withstand heavy use and occasional impacts.

Hygiene is another key benefit of stainless steel. The smooth surface prevents food buildup and bacteria growth, making it easy to clean and sanitize. Our bratt pan’s seamless construction eliminates crevices where food can accumulate, ensuring compliance with food safety regulations. Chinese commercial kitchen operators emphasize that easy-to-clean equipment reduces labor time and improves hygiene—two critical factors for successful food service businesses.

The stainless steel body also contributes to energy efficiency. It retains heat effectively, reducing the amount of energy needed to maintain cooking temperatures. This, combined with the induction heating system, results in the 90%-95% energy efficiency rating that sets our bratt pan apart from gas models. Our 2-years free exchangeable policy covers any manufacturing defects in the stainless steel construction, ensuring minimal downtime for your kitchen.

7. Temperature Control & Precision Cooking

Precise temperature control is essential for commercial cooking, where consistency is key to customer satisfaction. AT Cooker’s ATT-ABT BP300 features a sensor switch controller and real-time power level display, allowing chefs to set and monitor temperatures with accuracy.

The bratt pan’s temperature range (194℉ – 572℉ / 90℃ – 300℃) covers all cooking needs, from low-temperature braising to high-heat frying. The 8 adjustable power levels provide fine control, allowing chefs to tailor the heat to the specific dish being prepared. For example, delicate sauces can be cooked at a low power level to prevent burning, while deep frying requires a high power level to achieve the perfect crispiness.

The thermostatic control system maintains a constant temperature, eliminating fluctuations that can ruin large batches of food. This precision is particularly valuable for restaurants and catering companies that need to replicate dishes consistently across multiple locations or events. Chinese culinary professionals report that precise temperature control reduces food waste by 20%-30%, as there’s less risk of overcooking or undercooking.

The real-time power level display and LED screen make it easy to monitor the bratt pan’s operation, even in busy kitchen environments. The sensor switch is waterproof and resistant to grease, ensuring reliable performance for years. This level of control gives chefs the confidence to experiment with new recipes while maintaining the consistency that keeps customers coming back.

Bratt Pan vs. Traditional Cooking Equipment: Key Differences

| Feature | AT Cooker Bratt Pan ATT-ABT BP300 | Traditional Gas Fryer + Braiser + Steamer |

|---|---|---|

| Energy Efficiency | 90%-95% | 40%-60% |

| Cooking Functions | 7 (frying, braising, steaming, etc.) | 1-2 per appliance |

| Capacity | 300L | 50-100L per appliance |

| Space Required | 1700×1305×1050mm (single unit) | 3× the space (multiple units) |

| Safety Features | Anti-overheat, anti-dry heating, automatic fault detection | Basic safety features (no integrated protection) |

| Annual Energy Cost (USD) | $1,200-$1,800 | $3,500-$4,500 |

8. Ideal Applications: Who Benefits from a Bratt Pan?

A commercial bratt pan is a versatile tool that benefits a wide range of food service businesses. Its large capacity, multifunctionality, and efficiency make it ideal for:

Restaurants & Hotels: Busy restaurants and hotels that need to prepare large batches of food quickly and consistently. The bratt pan’s ability to handle multiple cooking methods means it can support diverse menus, from casual comfort food to fine dining dishes.

Catering Companies: Caterers often need to cook for hundreds of people at once, and a bratt pan’s 300L capacity makes it perfect for large-scale events like weddings, corporate functions, and festivals. The tilting and drainage features simplify transport and serving.

Institutional Kitchens: Schools, hospitals, and military facilities that serve meals to large groups on a daily basis. The bratt pan’s efficiency and durability reduce operational costs, while its multifunctionality supports nutritious menu options.

Food Processing Facilities: Businesses that produce prepared foods (like sauces, stews, or frozen meals) benefit from the bratt pan’s large capacity and precise temperature control. The stainless steel construction ensures compliance with food processing hygiene standards.

Our global stock availability means that businesses in the US, Germany, France, UK, Belgium, Italy, Spain, and Bulgaria can get their bratt pan quickly, with no lengthy lead times. This ensures minimal disruption to kitchen operations when upgrading or expanding equipment.

9. Maintenance & Long-Term Reliability

To ensure long-term reliability and safety, regular maintenance of a bratt pan is essential. AT Cooker’s ATT-ABT BP300 is designed for easy maintenance, with features that reduce downtime and repair costs.

Key maintenance tasks include cleaning the pan after each use, inspecting the tilting mechanism for wear, and checking the drainage system for clogs. The stainless steel body is easy to clean with mild detergent and a damp cloth, and the pan’s smooth surface prevents food buildup. For tough stains, the pan can be soaked in warm, soapy water—no abrasive cleaners needed.

The tilting mechanism should be inspected monthly for loose bolts or signs of wear. Our model uses high-quality bearings that require minimal lubrication (once every 6 months), ensuring smooth operation. The drainage system should be flushed regularly to prevent clogs from food particles, which can affect performance and safety.

AT Cooker provides detailed maintenance guides and video tutorials to help kitchen staff keep the bratt pan in top condition. Our 1-year free return policy and global support network ensure that any issues are resolved quickly. With proper maintenance, our bratt pan will provide reliable service for 8-10 years, delivering a strong return on investment.

AT Cooker Maintenance Tips for Bratt Pans

• Clean the pan immediately after use to prevent food from sticking. • Inspect the tilting mechanism monthly for loose parts. • Flush the drainage system weekly to remove debris. • Lubricate the tilting bearings every 6 months with food-grade oil. • Avoid using abrasive cleaners that can scratch the stainless steel surface. • Have the pan professionally inspected annually for electrical safety.

10. AT Cooker’s Recommendations for Choosing a Bratt Pan

After 15 years of serving commercial kitchens worldwide, AT Cooker has developed clear recommendations for choosing a bratt pan that meets your business’s needs. Here are our key tips:

- Prioritize Capacity: Choose a bratt pan with a capacity that matches your daily output. Our 300L model is ideal for large-scale operations, while smaller models (40L-150L) are available for smaller kitchens.

- Opt for Electric Induction: Electric induction bratt pans offer higher energy efficiency, faster heating, and safer operation than gas models—worth the higher upfront cost for long-term savings.

- Look for Multifunctionality: Ensure the bratt pan supports all the cooking methods you need (frying, braising, steaming, etc.) to maximize versatility.

- Check Safety Features: Choose a model with anti-overheat warning, anti-dry heating warning, and automatic fault detection to protect your staff and equipment.

- Choose Durable Materials: Select a bratt pan with 304# stainless steel construction for durability and hygiene.

- Consider After-Sales Support: Look for a supplier with a strong warranty and global support network to minimize downtime.

Our Electric Tiltable Bratt Pan ATT-ABT BP300 embodies all these recommendations, with a focus on efficiency, safety, and versatility. Backed by our 5-year warranty, 2-year free exchangeable policy, and 1-year free return guarantee, it’s an investment that will deliver value for years to come.

The advantages of bratt pan are clear: it saves space, reduces energy costs, improves safety, and supports diverse cooking needs—making it an indispensable tool for modern commercial kitchens. Whether you’re a restaurant owner, caterer, or institutional food service provider, a high-quality bratt pan will help you boost productivity and deliver consistent, delicious food to your customers.

If you’re ready to invest in a commercial bratt pan that delivers versatility, efficiency, and durability, contact our team today. We’ll help you choose the right model for your needs, provide a custom quote, and answer any questions you may have. With AT Cooker, you’ll get a bratt pan that’s designed to meet the unique challenges of your commercial kitchen—backed by industry-leading support and warranties.