The Real Cost of Electrical Upgrades for High-Power Commercial Induction Steamers

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

AT Cooker Executive Insight: Switching from gas to induction is a strategic investment that slashes utility bills by up to 50%. However, installing high-power units like the 25KW AT Cooker ZFGT-A V25 often requires an electrical infrastructure upgrade. How much does this really cost? We break down the expenses—from copper wire to labor—to give you a transparent look at the ROI of modernizing your commercial kitchen.

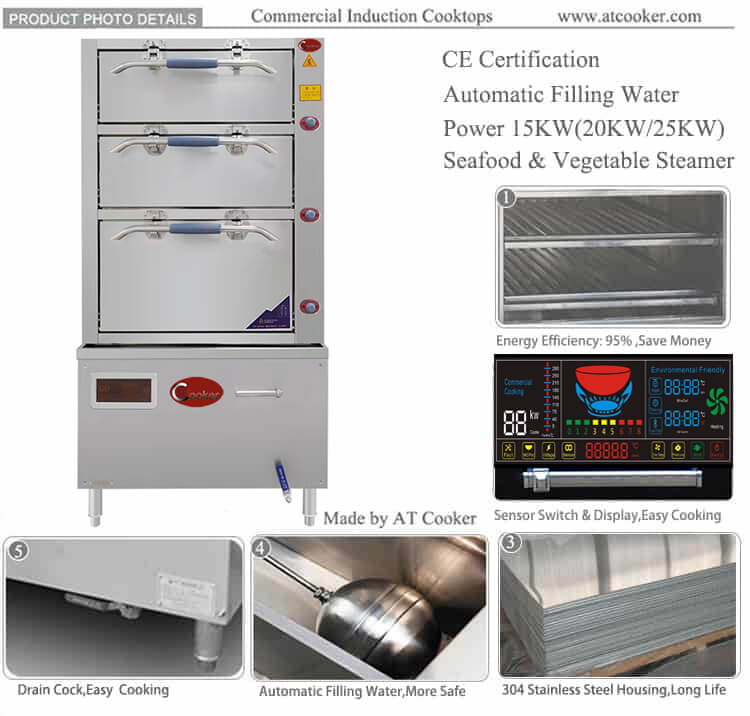

When restaurant owners consider upgrading to induction technology, the first question is usually about the equipment price. The second, and often more important question, is: “How much will it cost to wire this thing?” It is a valid concern. A high-efficiency machine like our Vegetable/seafood steamer ZFGT-A V25 delivers incredible performance—heating to 180℃ rapidly with 95% efficiency—but it requires a robust 380V, 3-phase electrical connection.

Unlike gas equipment, which involves plumbing pipes, electric induction involves panels, breakers, and copper cabling. The commercial kitchen electrical upgrade cost can range from a minor expense to a significant capital project. However, looking at the sticker price alone is misleading. You must calculate the Total Cost of Ownership (TCO), factoring in the massive energy savings and reduced maintenance.

In this guide, AT Cooker draws on 15 years of industry experience to peel back the layers of installation pricing, helping you budget accurately for your kitchen’s future.

Commercial Kitchen Equipment -from AT Cooker

- As a brand manufacturer of the professional commercial induction cooking equipment, AT Cooker has responded to restaurants’ & hotels’ needs and research normative commercial cooking equipment using the very latest induction technology.

- These seamless, real commercial quality commercial cooking equipment provides us with the opportunity to incorporate equipment of our choice into one seamless, multipurpose cooking equipment creating an efficient, low cost, safe, green and sustainable commercial kitchen. We have standerd equipment can service many commercial kitchens.

- AT Cooker always offers professional service. From material, design, to producing, we focuse on quality, performance and reliability to ensures the best solution is delivered for each and every one of our customers. Have a commercial kitchen? We will be one of your best partners.

Work Voltage

| Single-Phase | Three-Phase |

|---|---|

| 120V, 220V | 208V/ 240V, 380V, 480V |

Global In-Stock + Fast Pickup

| US | UK | Germany | France |

|---|---|---|---|

| Italy | Spain | Belgium | Bulgaria |

1. Breakdown of Licensed Electrician Labor Rates vs Material Expenses

The total cost of an upgrade is a split between parts and labor. Material costs (wires, panels, breakers) are relatively fixed, but labor varies wildly by region. In the US, a licensed commercial electrician charges between $85 and $150 per hour.

For a straightforward dedicated line installation for the ZFGT-A V25, expect:

- Materials: 20-30% of the budget (Breakers, Conduit, Copper).

- Labor: 70-80% of the budget (Pulling wire, panel work, permitting).

Hiring a cheap, unlicensed handyman is illegal for commercial work and dangerous. Always prioritize a licensed professional to ensure your warranty and insurance remain valid.

2. Cost Comparison: Upgrading Existing Panels vs Installing New Sub-Panels

If your main breaker panel is full, you have two choices. Installing a sub-panel is usually cheaper ($800 – $1,500) and faster. It involves adding a smaller box next to your main panel to create more slots.

However, if your main service amperage (e.g., 200 Amps) is maxed out, a sub-panel won’t help. You need a Main Service Upgrade (e.g., to 400 Amps). This is expensive ($3,000 – $8,000+) because it involves the utility company and shutting down power to the building. Verify your total amp load first.

3. The Impact of Cable Run Length on Copper Wire Material Costs

Copper is expensive. The distance from your breaker box to the kitchen location of the ZFGT-A V25 dramatically affects the price. A 10-foot run might cost $100 in wire. A 100-foot run through a ceiling plenum could cost $800+ in wire alone.

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

4. Calculating the Payback Period: Energy Savings vs Upfront Electrical Costs

This is where the math gets exciting. Yes, spending $3,000 on an electrical upgrade hurts. But let’s look at the operational savings.

A gas steamer wastes 60% of its energy into the air. The ZFGT-A V25 puts 95% of its energy into the food. In a busy dim sum restaurant or hotel kitchen, this efficiency difference can save $300-$500 per month in utility bills.

ROI Snapshot

Upgrade Cost: $4,000

Monthly Savings: $400 (Energy + Water + HVAC)

Payback Period: 10 Months

After less than a year, the electrical upgrade is paid for, and the savings become pure profit.

5. Typical Permit and Inspection Fees for Commercial Kitchen Alterations

Don’t forget the government. Almost every jurisdiction requires an electrical permit for adding a new circuit over 20 Amps. Permit fees typically range from $100 to $500. While tempting to skip, unpermitted work can lead to fines, insurance denial in a fire, and trouble when selling the business.

6. Price Differences Between Installing 208V and 380V Circuit Configurations

In the US, 208V is standard. In Europe and Asia, 380V/400V is standard. The AT Cooker ZFGT-A V25 is optimized for 380V to keep amperage low (~38 Amps).

If your building only has 208V, running a 25KW machine requires nearly 70 Amps. This requires much thicker, more expensive wire and a larger breaker. Sometimes, installing a step-up transformer (to create 380V) is actually cheaper than running heavy-gauge copper for 208V, especially over long distances.

7. Factoring in Revenue Loss from Kitchen Downtime During Installation

An upgrade requires shutting off power. If you schedule this during prep time, you lose money. Smart operators schedule electrical work overnight or on closed days. The cost of “downtime” should be zero if planned correctly. Our energy efficient commercial cooking equipment is designed for plug-and-play installation once the wire is ready, minimizing disruption.

8. HVAC Savings: How Lower Heat Load Offsets Electrical Infrastructure Costs

Gas steamers turn kitchens into saunas. Your AC works overtime to fight that heat. Induction steamers like the ZFGT-A V25 release minimal ambient heat.

Reducing your kitchen temperature by 10-15 degrees can lower your cooling bill by 30%. This “invisible” saving helps offset the initial commercial kitchen electrical upgrade cost rapidly.

9. Long-Term Maintenance Costs: Electrical Wiring vs Gas Plumbing Repairs

Gas lines leak. Pilot lights fail. Burners clog. Gas infrastructure requires regular, expensive maintenance. Electrical wiring, once installed correctly, is virtually maintenance-free for decades.

By switching to the ZFGT-A V25, you eliminate the headaches of gas plumbing repairs. The long-term stability of an electrical connection far outweighs the initial setup cost.

10. Understanding Grid Capacity Expansion Fees for High-Wattage Equipment

In rare cases, your local utility might charge a fee if your new equipment requires them to upgrade the transformer on the street pole. This is more common in rural areas or undersized strip malls. Always check with your landlord or utility provider if you are adding significant load (e.g., converting an entire gas line to electric).

11. Budgeting for Standardized Fire-Resistant Cables in High-Temperature Zones

Commercial kitchens are hot, greasy environments. Standard vinyl-coated wire (NM cable) is not allowed. You must budget for commercial-grade wire (THHN/THWN) run inside metal conduit (EMT).

Using the correct fire-resistant materials protects your investment and ensures the AT Cooker steamer receives clean, safe power for years to come.

| Cost Factor | Gas Installation | Induction Installation (380V) |

|---|---|---|

| Connection | Plumbing & Gas Flex | Breaker & Copper Wire |

| Ventilation | Expensive Makeup Air | Standard Hood |

| Monthly Energy | High (40% Efficiency) | Low (95% Efficiency) |

| Maintenance | Frequent (Leaks/Clogs) | Minimal (Solid State) |

5-year Warranty | 2-year Free Exchangeable | 1-year Free Return

Final Thoughts from AT Cooker

The “cost” of an electrical upgrade is actually an entry fee to a more profitable, efficient business model. While writing a check for electrical work isn’t fun, the return on investment from the ZFGT-A V25 is undeniable. Lower bills, faster cooking, and a happier staff make it worth every penny.

We are ready to support your transition. With stock in the USA, Germany, France, and beyond, we can get you the equipment fast. For installation guidance, visit our About Us page. For pricing data on construction materials, refer to resources like RSMeans or China’s Mysteel for copper trends.